Type 1032

5

For clockwise output rotation, refer to figure 5. With

actuator pistons installed as shown in figure 5 (fail-

open action for valves with clockwise to close disk

rotation), the supply pressure is applied to port A. This

pressure forces the pistons apart, compresses the

springs, and closes the valve. The linear travel of the

pistons is converted to a clockwise rotation of the pin-

ion and valve shaft by the rack-to-pinion connection.

The volume on top of each piston is exhausted

through port B. Upon loss or removal of supply pres-

sure, the compressed springs move the pistons to-

gether and open the valve.

Maintenance

Actuator parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency

of inspection and replacement depends upon the se-

verity of service conditions. Instructions are given in

subsequent sections for disassembly and assembly of

the actuator.

Because of the care Fisher takes in meeting all

manufacturing requirements (heat treating, dimension-

al tolerances, etc.), use only replacement parts

manufactured by Fisher.

WARNING

Avoid personal injury from sudden re-

lease of process pressure. Before per-

forming any maintenance operations:

Disconnect any operating lines pro-

viding air pressure, or a control signal

to the actuator. Be sure the actuator

cannot suddenly open or close the

valve.

Use bypass valves or completely

shut off the process to isolate the valve

from process pressure. Relieve process

pressure on both sides of the valve.

Drain the process media from both

sides of the valve.

Vent the power actuator loading

pressure and relieve any actuator spring

precompression.

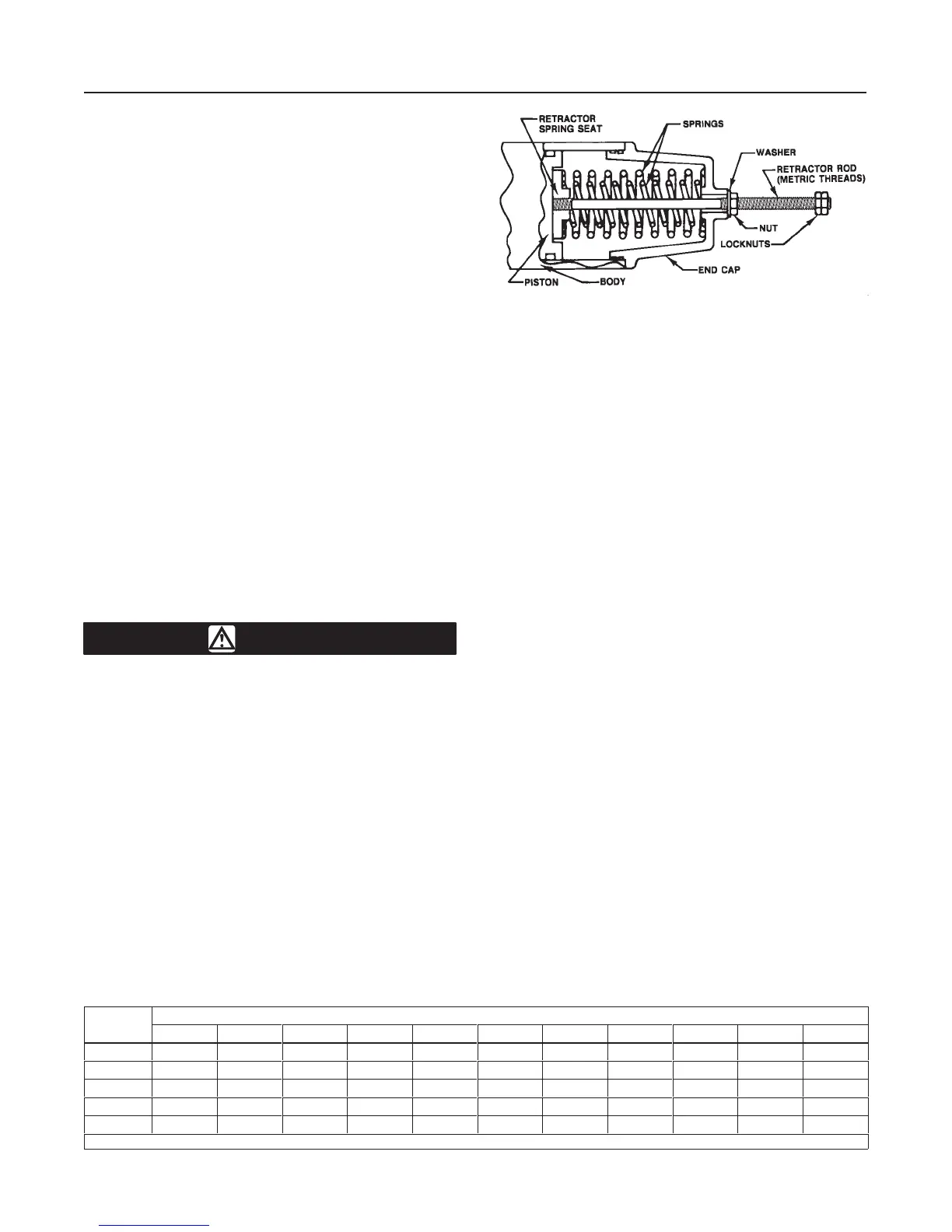

Figure

6. Spring-Return Actuator End Cap

with Retractor Rod Installed

A5833-1 / IL

Use lock-out procedures to be sure

that the above measures stay in effect

while you work on the equipment.

Disassembly

The following procedure describes how the actuator

can be completely disassembled. When inspection or

repairs are required, perform only those steps neces-

sary to accomplish the task. Key numbers referenced

in the following steps are shown in figure 10 for

double-acting actuators and in figure 11 for spring-re-

turn actuators unless otherwise indicated. Disassem-

bly procedures are identical for both double-acting and

spring-return actuators except for removal of the end

caps (key 4).

1. Isolate the control valve from the line pressure, re-

lease pressure from both sides of the valve body, and

drain the process media from both sides of the valve.

If using a power actuator, also shut-off all pressure

lines to the power actuator, release all pressure from

the actuator. Use lock-out procedures to be sure that

the above measures stay in effect while you work on

the equipment. Remove the actuator from the valve.

2. For double-acting actuators, remove the end

caps as described below. The actuator has two end

caps. Perform the same steps on both end caps.

a. Loosen the nut on the safety key (key 5) and

unscrew the threaded portion.

b. Remove the flexible stainless steel safety key

(key 5) by gently pulling on the nut and at the same

time turning the end cap (key 4) towards the safety

key. For larger models, use a wrench on the end

cap boss to assist in turning the end cap.

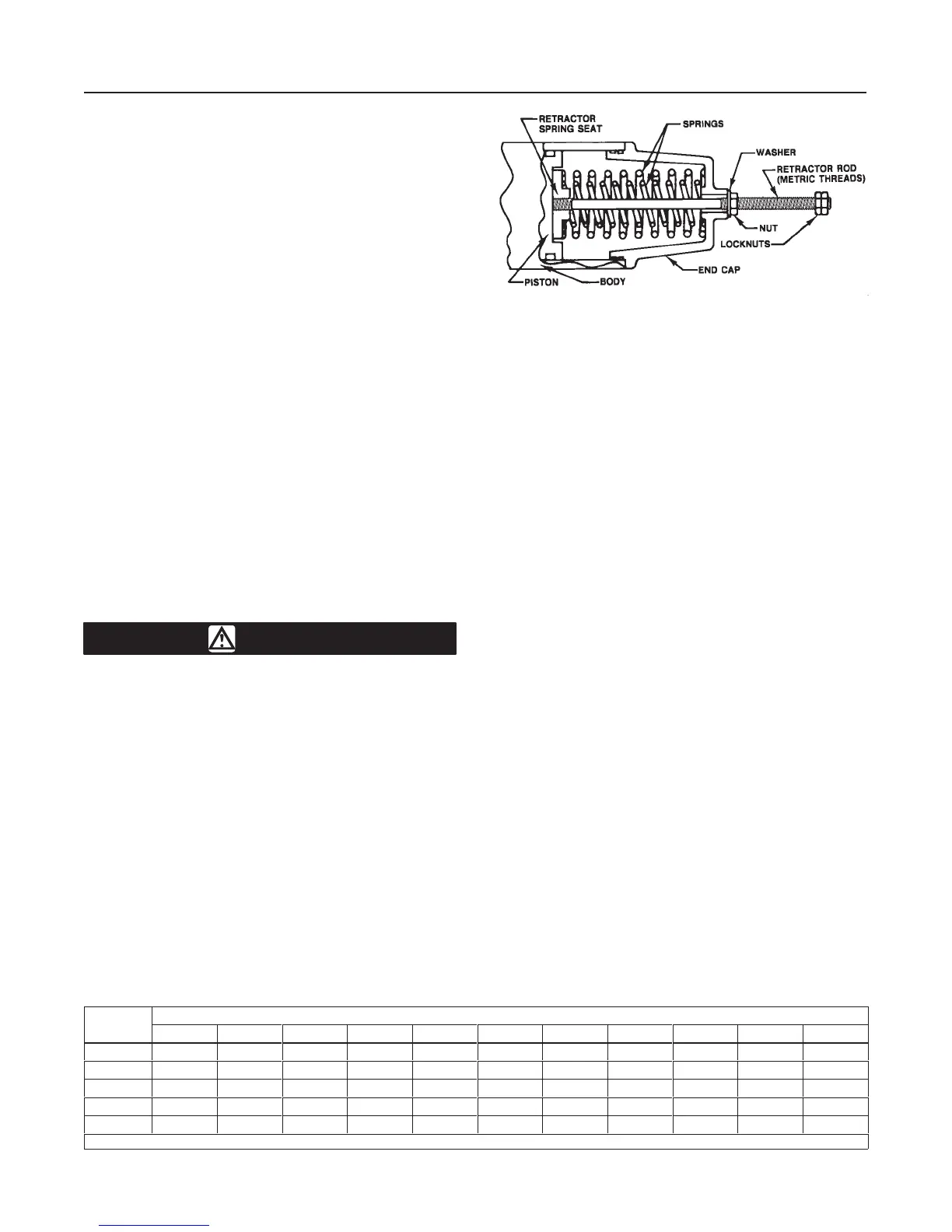

MODEL NUMBER

45 70 130 185 280 425A 680A 1125 1370 2585 4580

A 7.09/180 8.07/205 6.30/160 9.65/245 5.71/145 11.22/285 13.98/355 9.25/235 16.34/415 19.29/490 20.87/530

B 2.99/76 3.23/82 3.62/92 3.94/100 2.95/75 5.00/125 5.87/149 4.92/125 6.89/175 8.23/209 9.92/252

C 0.24/6 0.55/14 0.55/14 0.51/13 0.55/14 0.51/13 0.51/13 0.91/23 0.59/15 0.79/20 0.79/20

D 0.20/5 0.31/8 0.31/8 0.31/8 0.39/10 0.31/8 0.47/12 0.47/12 0.47/12 0.47/12 0.79/20

E

(1)

M5 M8 M8 M8 M10 M8 M12 M12 M12 M12 M20

1. Metric thread designation.

Loading...

Loading...