Type 1032

8

6. Carefully install the pinion (key 2) into the body

(key 1), while making certain that the upper and lower

pinion bearings do not catch on the bores in the body

and become dislodged.

7. Place the thrust bearing (key 19) and the thrust

washer (key 20) over the pinion. Using a snap ring

tool, install the snap ring (key 23).

Installing the Pistons

Key numbers are shown in figures 10 and 11 unless

otherwise indicated.

1. Liberally apply a lithium-based grease to the pis-

tons (key 3) and to the actuator body bore.

2. Apply a light coat of lithium-based grease to the

piston O-rings (key 12), and then install them in their

grooves in the pistons.

3. Insert the piston bearings (key 16) into the holding

grooves of the piston with the piston bearing tag facing

away from piston head. Push the piston bearings in

until the bearing tag snaps into its slot in the piston.

4. Insert one piston (key 3), with rack teeth toward the

pinion (key 2), into each end of the body bore. Make

certain the alignment groove in the end of each piston

is parallel to the long axis of the pinion.

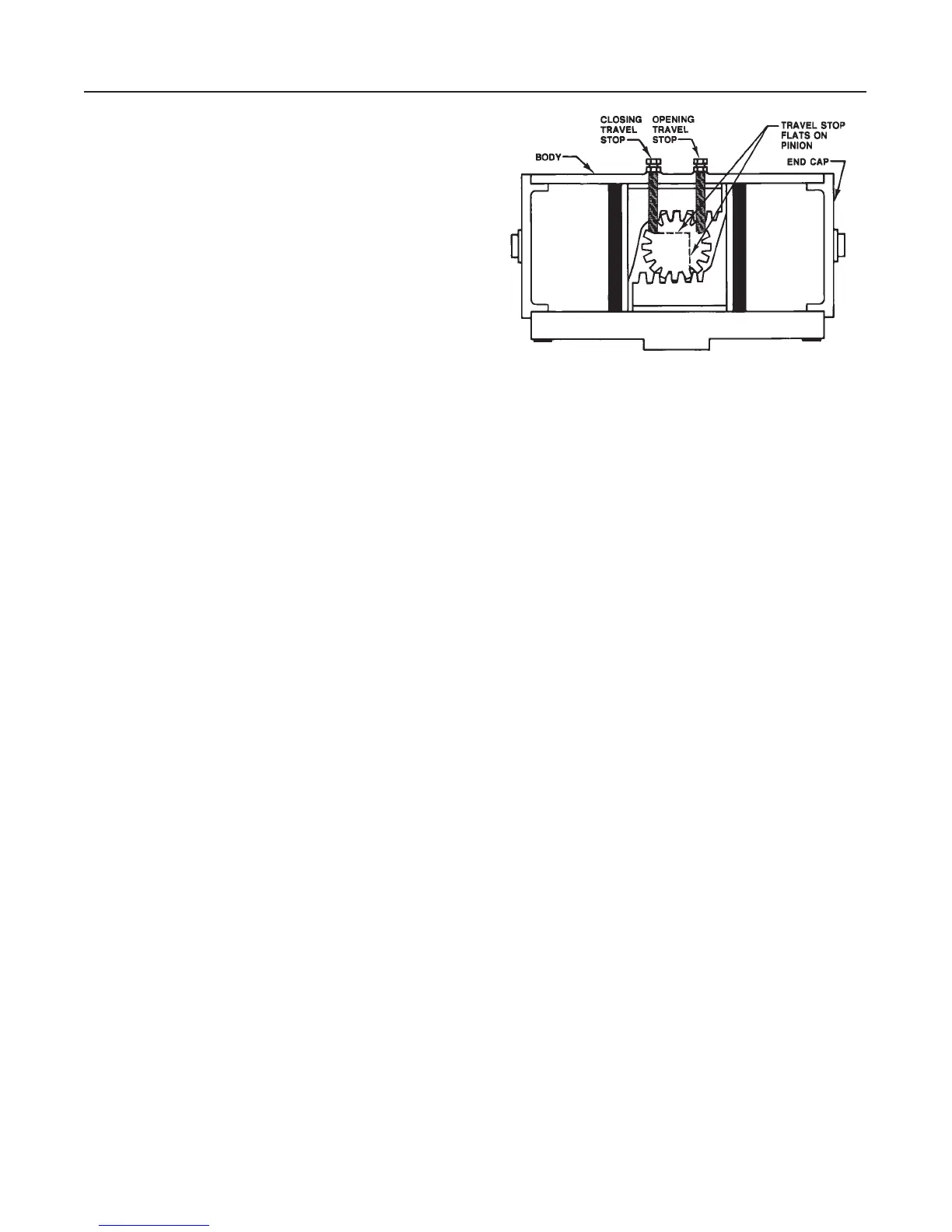

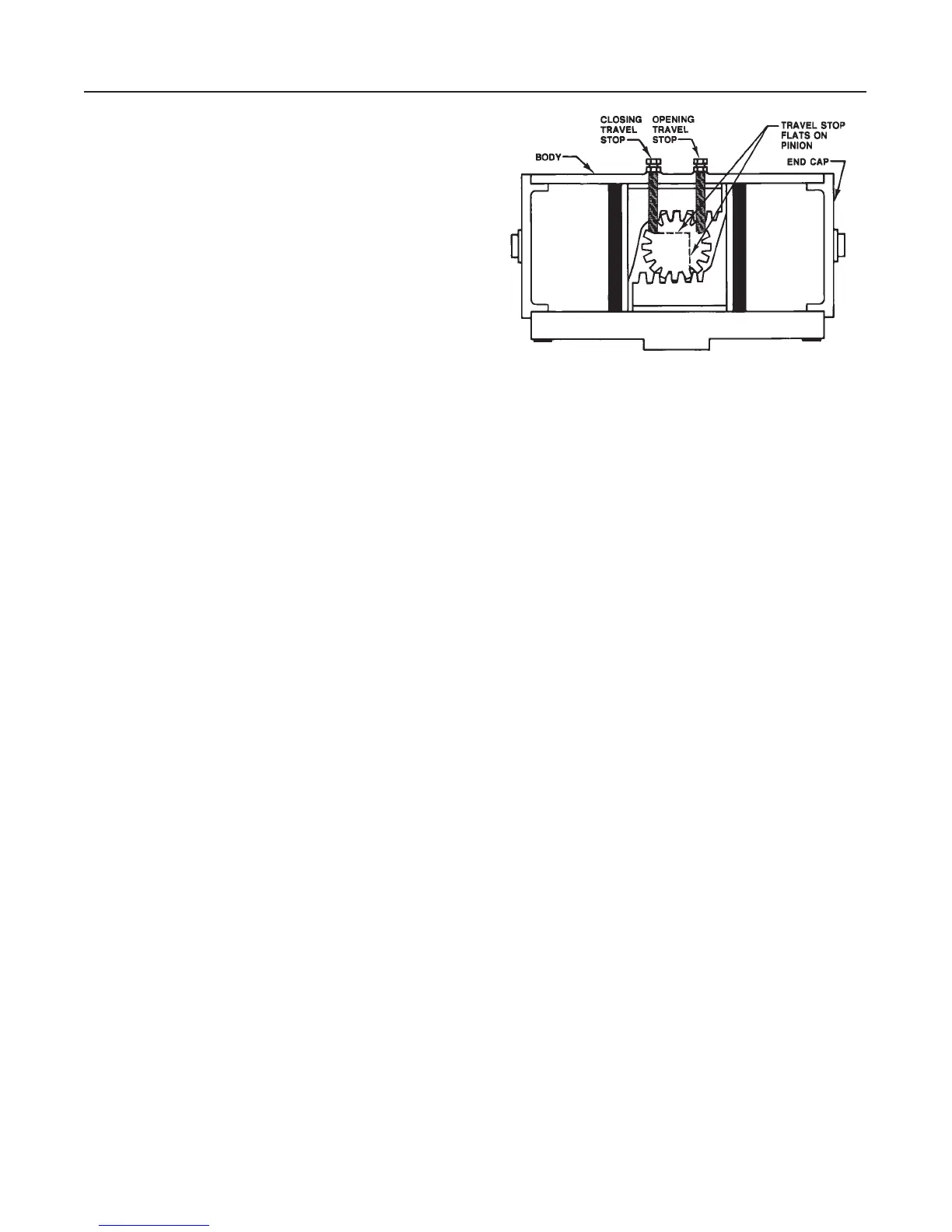

5. Rotate the pinion (key 2) so its travel stop flats are

properly oriented for correct actuator output rotation

and for correct valve rotation (see figure 8). The orien-

tation shown in figure 8 is correct for counterclockwise

output rotation of the actuator and clockwise to close

valves.

6. Push both pistons together until their racks are in

contact with the pinion (key 2). Rotate the pinion

clockwise to draw the pistons together.

Note

When the pistons are together and the

rack teeth are properly engaged by the

teeth on the pinion, the two travel stop

flats will each be at a right angle to an

axis of the body.

Installing the Travel Stops

Key numbers referenced in the following steps are

shown in figure 10 for double-acting actuators and in

figure 11 for spring-return actuators unless otherwise

indicated.

1. Thread the travel stop lock nuts (key 10) on the

travel stop bolts (key 9) if they were removed. Install

Figure 9. Travel Stop Installation for

Counterclockwise Output Rotation

A5835/ IL

the sealing washers (key 11) against the travel stop

lock nuts.

2. With the pistons together, screw in a travel stop

bolt (key 9) for the closing travel stop (see figure 9)

until the bolt just touches the travel stop flat on the

pinion. It may be necessary to move the travel stop

lock nut on the bolt to allow the bolt to touch the pin-

ion.

3. Rotate the pinion 90 to drive the pistons apart.

Make certain the rotation is only 90. Screw in a travel

stop bolt (key 9) for the opening travel stop (see figure

9) until the bolt just touches the travel stop flat on the

pinion. It may be necessary to move the travel stop

lock nut on the bolt to allow the bolt to touch the pin-

ion.

4. Make the final travel stop adjustments in accor-

dance with the Travel Stop Adjustments procedure in

the Installation section after the end caps are installed

and the actuator is mounted on the valve.

Installing the End Caps on Double-Acting

Actuators

Assemble and install the end caps as described be-

low. The actuator has two end caps. Perform these

same steps on both end caps. Key number locations

are shown in figure 10.

1. Apply a lithium-based grease to the end of the

body bore and to the surface of the end cap (key 4)

that fits into the body bore. Make certain the grease

gets into the grooves of the end cap.

2. Apply a light coat of lithium-based grease to the

end cap O-ring (key 13), and then install it in its

groove of the end cap (key 4). The O-ring groove is

the groove adjacent to the flange on the end cap.

3. Insert the end cap (key 4) into the body bore.

Loading...

Loading...