Type EZR

11

2. Back out the pilot adjusting screw(s).

3. For easy initial startup, set the restrictor to the “8”

position. For future startups, the restrictor can be

left in the desired run position.

4. SLOWLY OPEn the valves in the following order:

a. Pilot supply and control line valve(s), if used

b. Inlet block valve

c. Outlet block valve

5.

For a 161 Series pilot with Type 112 restrictor,

turn the restrictor(s) to position “2” or to the desired

run position. For a PRX Series pilot, turn the

restrictor screw 1 turn counterclockwise from

fully seated (turn restrictor fully clockwise then 1

turn counterclockwise) and the damper screw

fully counterclockwise.

6.

set the pilot to the

desired outlet (control) pressure according to the

pilot adjustment procedure

.

adjust the upstream working

pilot until intermediate pressure is higher than

the desired setpoint of the monitor pilot. Adjust

the downstream monitoring pilot to the desired

monitoring takeover pressure. Reduce the

upstream pilot to the normal outlet pressure setting.

adjust the downstream working pilot to a setpoint

higher than the setpoint of the monitor pilot.

Adjust the upstream monitoring pilot to the desired

monitor takeover pressure. Reduce the downstream

pilot setting to normal outlet pressure setting.

adjust the

setpoint of the upstream monitor pilot to the desired

maximum pressure. Adjust the upstream working

pilot to the desired intermediate pressure setting.

Adjust the downstream pilot to a pressure setting

slightly above the upstream monitor pilot pressure

setting. Adjust the upstream monitor pilot to its

desired setpoint. The setpoint of the monitor pilot

should be adjusted at least to the guidelines shown

in Table 9. The maximum may be greater. Then,

establish nal desired downstream pressure by

adjusting the downstream working regulator pilot.

remove the pilot closing cap

(key 16, Figure 19 or key 22, Figure 20) and, on

161EB Series only, loosen the locknut (key 12,

Figure 19). Turn the adjusting screw (key 11,

Figure 19 or key 35, Figure 20) into the spring case

(key 2, Figure 19 or key 3, Figure 20) to increase the

downstream pressure. Turn the adjusting screw out of

the spring case to decrease the downstream pressure.

loosen locknut

(key 2) and turn the adjusting screw into the spring case

to increase (or out of the spring case to decrease) the

downstream pressure. When the required downstream

pressure is maintained for several minutes, tighten the

locknut to lock the adjusting screw in position

and replace the pilot closing cap.

The Restrictor and Damper screws on the PRX Series

pilot control the regulator’s proportional band (droop)

and speed of response. Table 7 includes the appropriate

settings for low ow operation. For additional tuning

follow the steps outlined below:

1. Start with the restrictor screw 1 turn

counterclockwise from fully seated (turn restrictor

fully clockwise then 1 turn counterclockwise) and

the damper screw fully counterclockwise.

2. Turn damper screw clockwise until desired

performance is achieved. This reduces the ow

path of the damper. If the damper becomes fully

seated (no longer able to turn clockwise) and the

desired performance has not been achieved, return

the damper screw to the fully counterclockwise position.

!

WARnInG

3. Turn the restrictor screw an additional turn

counterclockwise from fully seated. This increases

the ow path of the restrictor. If additional tuning

is required, repeat step 2. Follow this method until

desired performance is achieved.

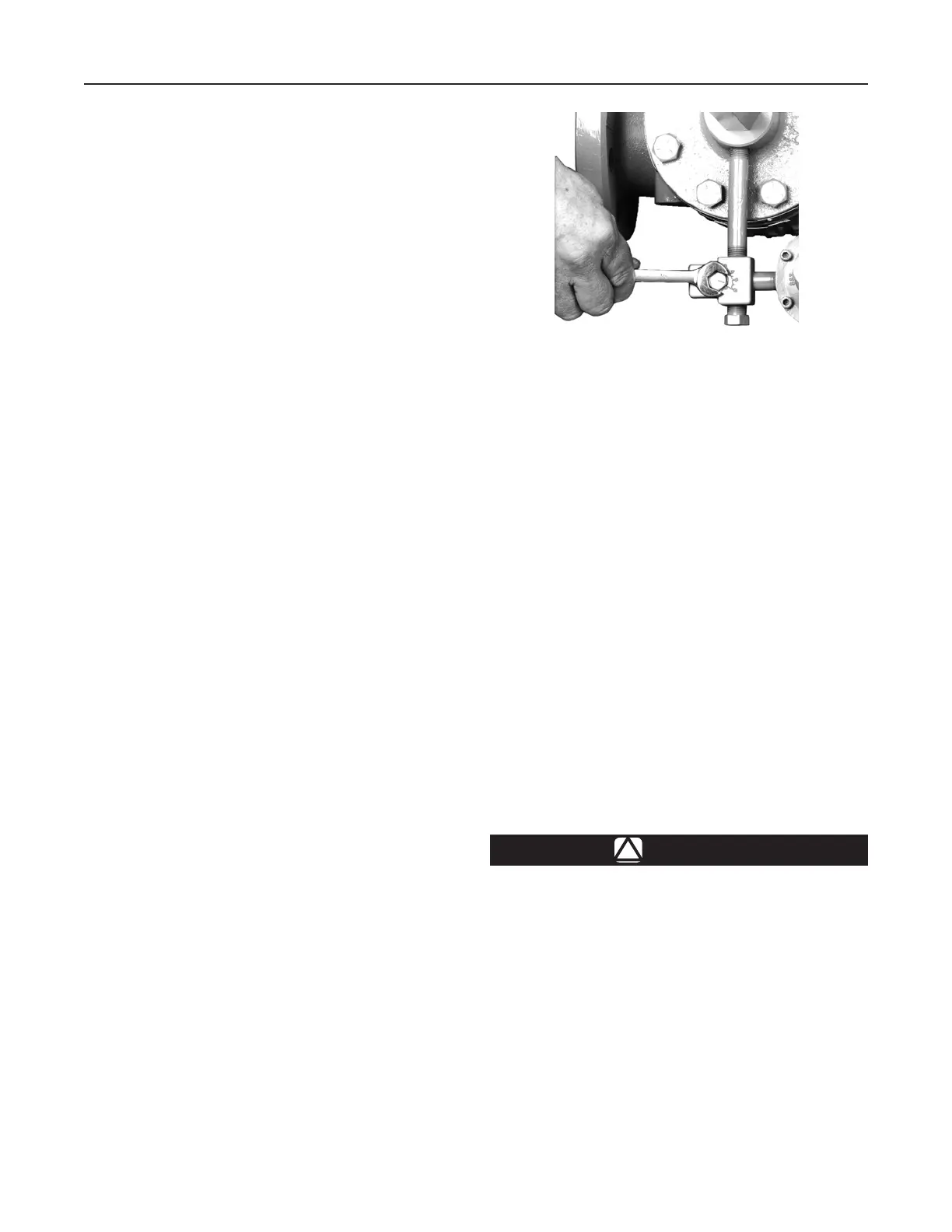

The Type 112 restrictor controls the regulator’s

proportional band (droop) and speed of response. The

restrictor can be used to ne tune the regulator for

Figure 6. Restrictor Adjustment

W4559_1

Loading...

Loading...