Instruction Manual

D103198X012

i2P-100 Transducer

July 2014

11

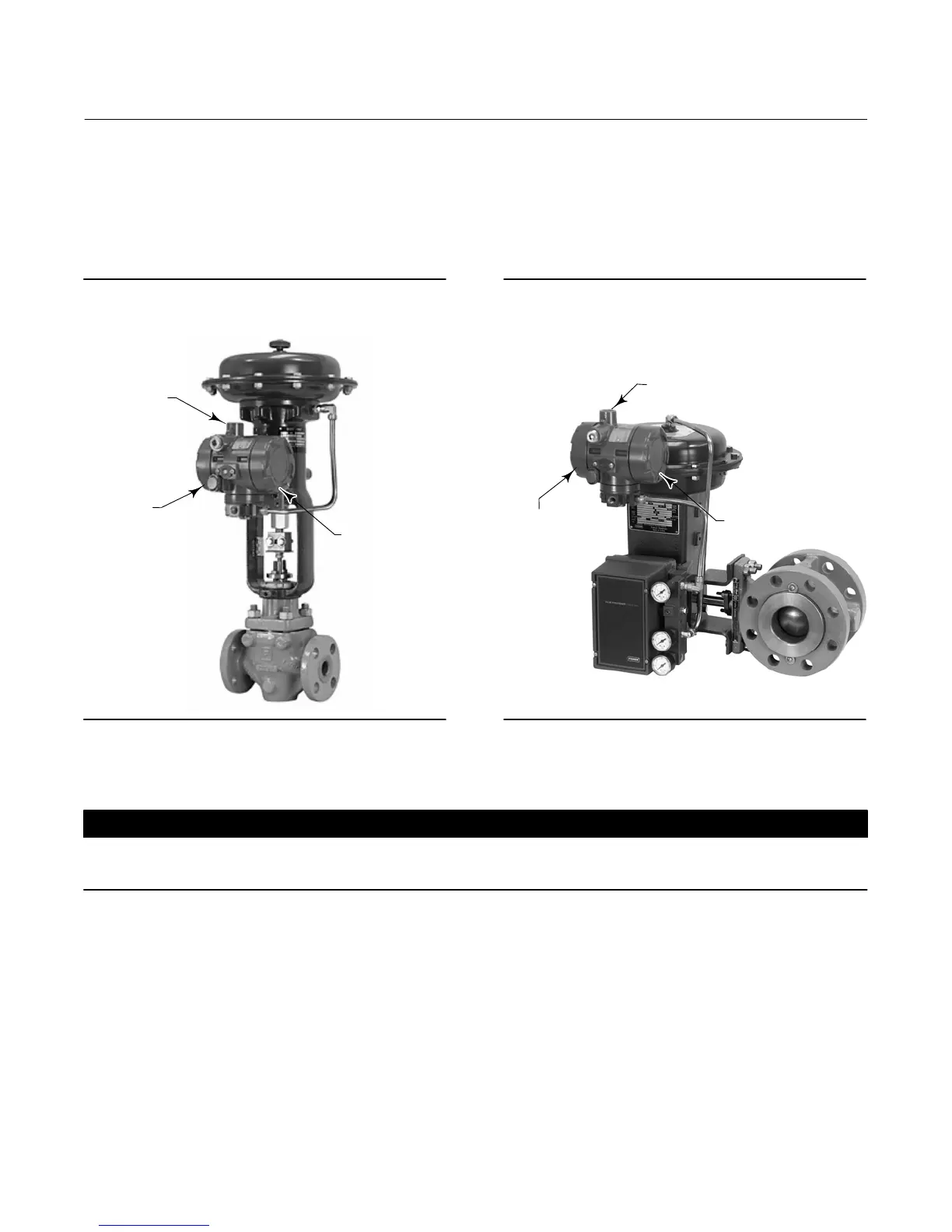

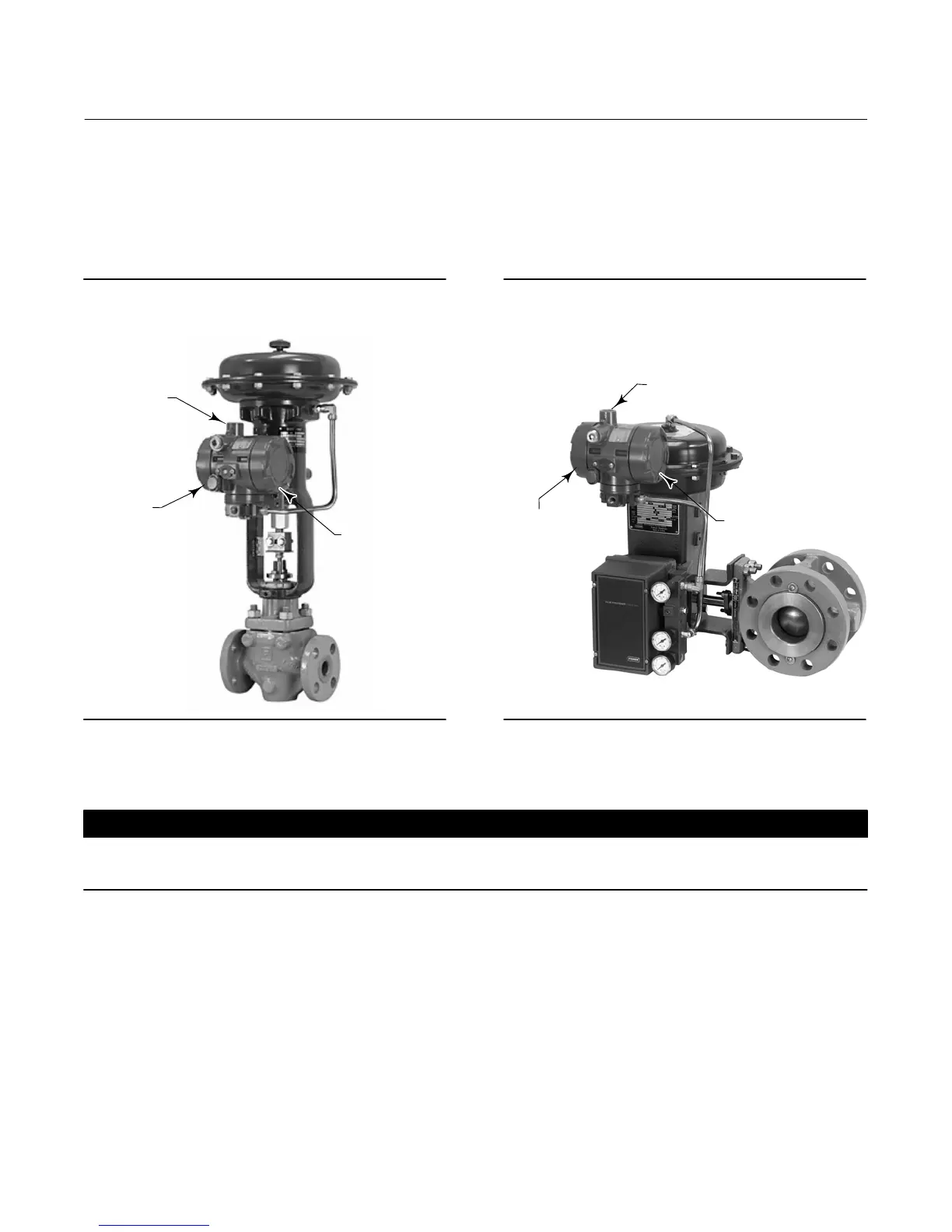

Mounting

When a transducer is ordered as part of a control valve assembly, the factory mounts the transducer on the actuator

and connects the necessary tubing, then adjusts the transducer as specified on the order. See figures 3 and 4 for

typical mounting configurations.

Figure 3. Fisher i2P‐100 Electro‐Pneumatic

Transducer Mounted on a Size 30 667 Sliding‐Stem

Actuator

W8723

CONDUIT

CONNECTION

FIELD

TERMINATION AND

ELECTRONICS

MODULE CAP

CONVERTER

MODULE CAP

Figure 4. Fisher i2P‐100 Electro‐Pneumatic

Transducer Mounted on a Size 33 1052 Rotary

Actuator with 3610J Positioner and V300B Rotary

Valve

W8693

CONDUIT

CONNECTION

FIELD TERMINATION

AND ELECTRONICS

MODULE CAP

CONVERTER

MODULE CAP

Transducers also can be ordered separately for mounting on a control valve assembly already in service, or for

mounting on a 2 inch diameter pipestand, or a flat surface. The transducer may be ordered either with or without

mounting parts.

CAUTION

Do not mount the vent in a downward position as the vent will not drain properly and may become blocked with ice or

debris, resulting in process instability.

Mounting parts include a mounting plate and bolts and, if ordered for pipestand mounting, a pipe clamp. Tubing is not

included if the transducer is not factory mounted. Use 3/8‐inch diameter tubing for all input and output connections.

The length of tubing between the transducer output and the final control element should be as short as possible.

Transducer overall dimensions are shown in figure 5. If weatherproofing is required, mount the transducer so that the

vent can drain. Do not allow moisture or condensate to collect in the vent.

Pneumatic Connections

As shown in figure 5, all pressure connections on the transducer are 1/4 NPT internal connections. Use 3/8‐inch tubing

for all pressure connections. Refer to the vent subsection below for remote vent connections.

Loading...

Loading...