Instruction Manual

D103198X012

i2P-100 Transducer

July 2014

18

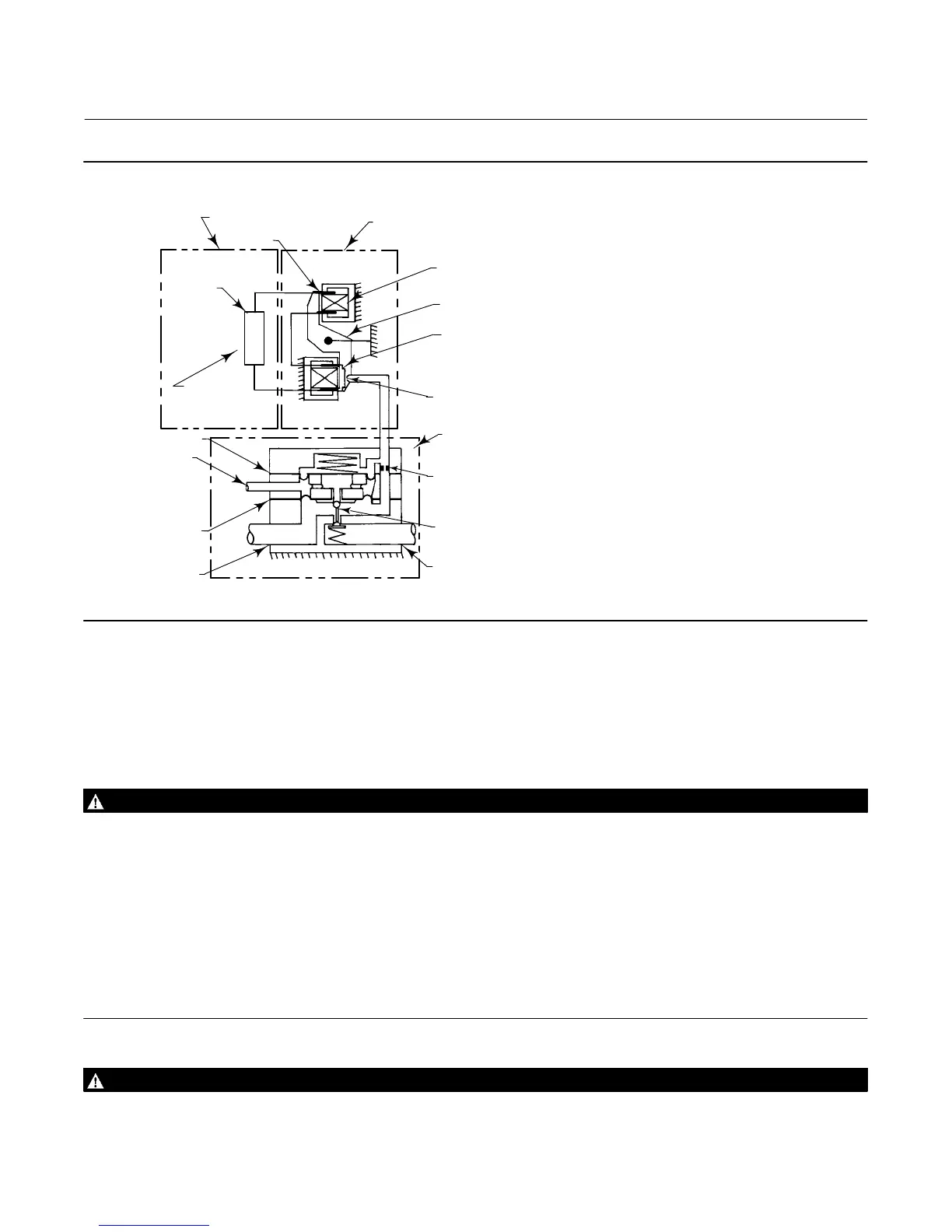

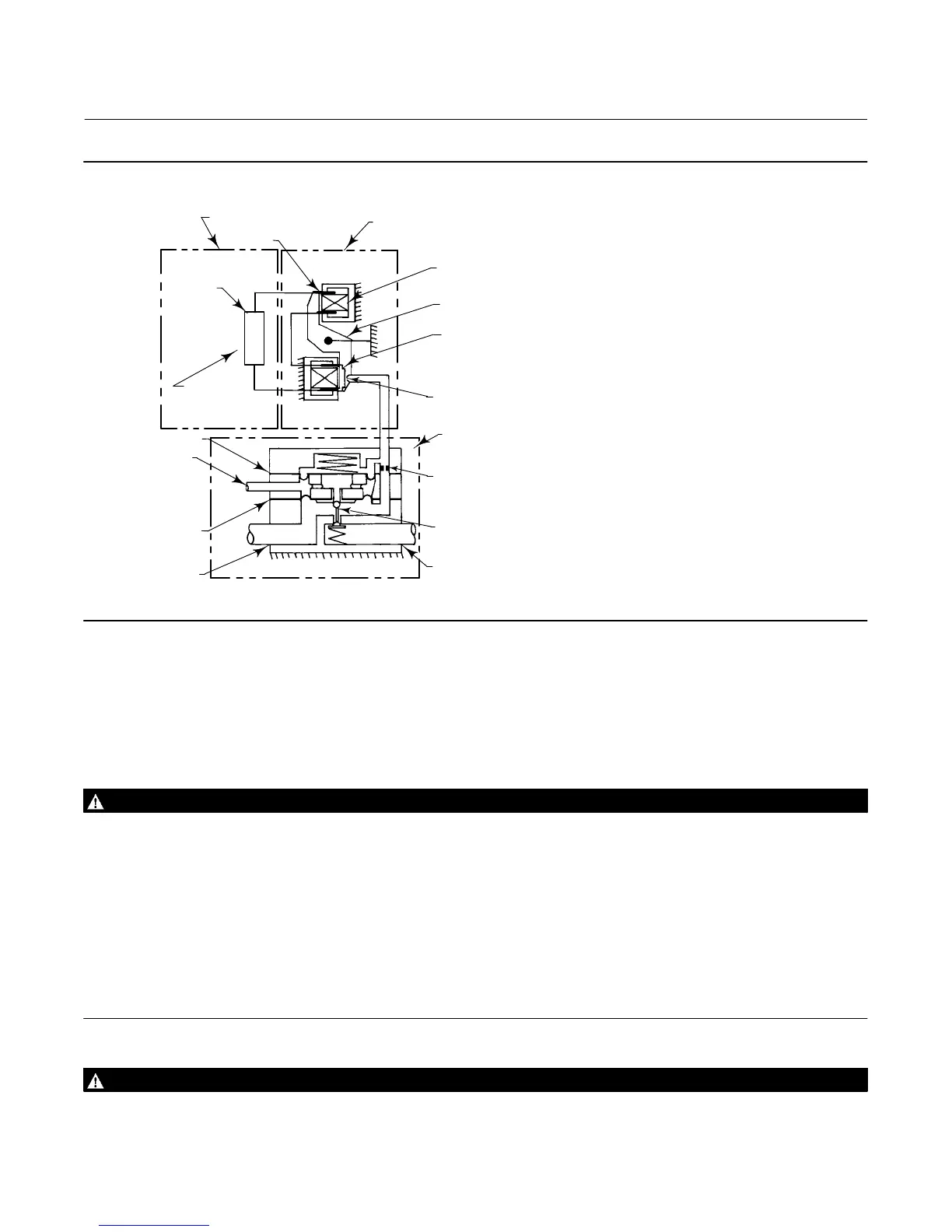

Figure 11. Fisher i2P‐100 Transducer Schematic

COIL

ZERO

AND

SPAN

CIRCUIT

DC

CURRENT

INPUT SIGNAL

PNEUMATIC RELAY

DIAPHRAGM

EXHAUST

DIAPHRAGM

OUTPUT

PRESSURE

MAGNET

BEAM

FLAPPER

NOZZLE

RESTRICTION

VALVE PLUG

SUPPLY PRESSURE

A3877-2

-

+

{

CURRENT‐TO‐PRESSURE

CONVERTER ASSEMBLY

FIELD TERMINATOR AND

ELECTRONICS CIRCUIT

F

F

Maintenance

Due to normal wear or damage from external sources such as debris in the supply medium, periodic maintenance or

repair of the transducer may be necessary. Maintenance of the transducer consists of troubleshooting, removal for

inspection, and replacement of component parts, as well as removal and inspection of the external removable

filter/restriction and cleaning or replacing as necessary (see figure 1).

WARNING

To avoid personal injury or property damage from the sudden release of pressure, air or natural gas:

D Always wear protective clothing, gloves, and eyewear when performing any maintenance operations.

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

WARNING

When using natural gas as the supply medium, or for explosion proof applications, the following warnings also apply:

Loading...

Loading...