Instruction Manual

D103198X012

i2P-100 Transducer

July 2014

5

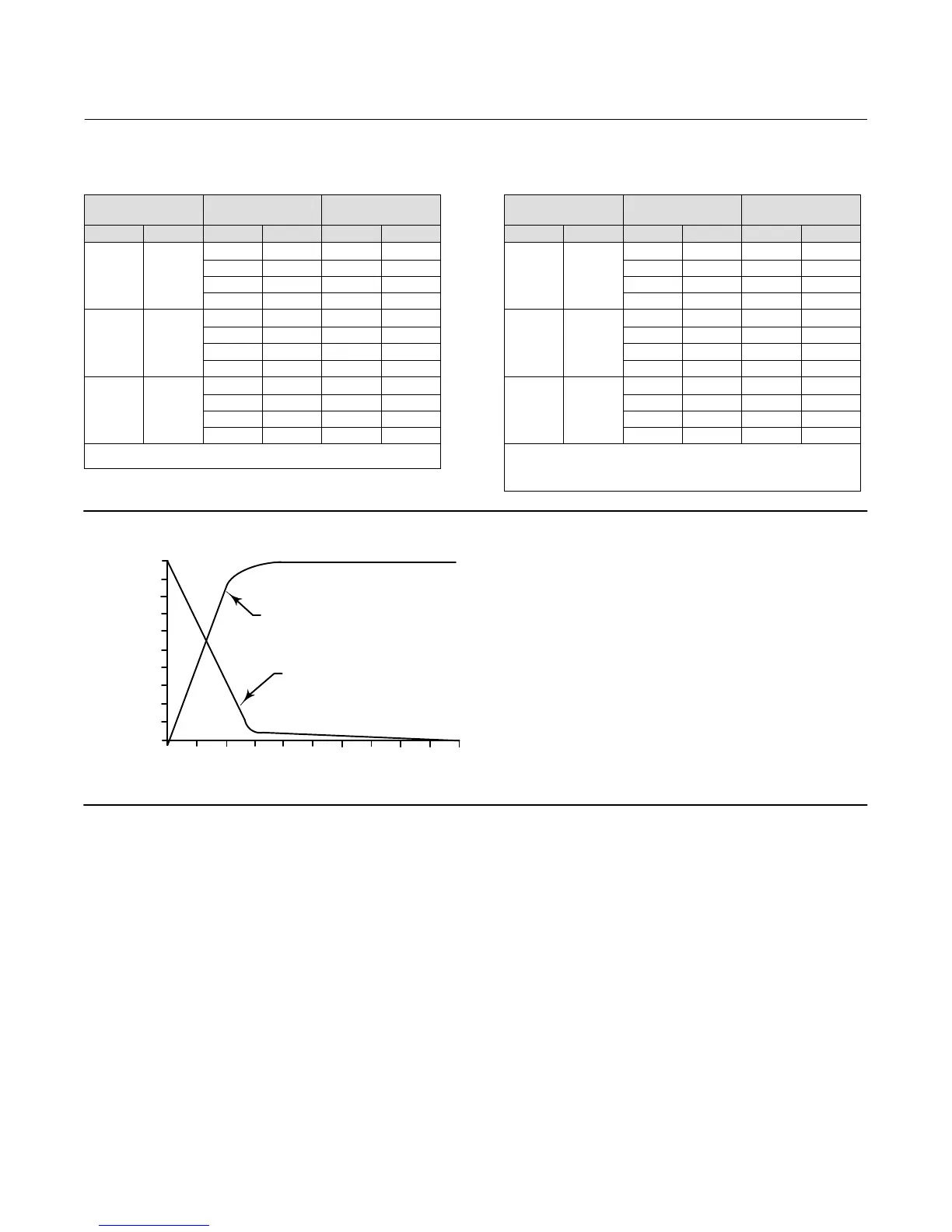

Table 3. Maximum Steady-State Flow Rate (Air)

SUPPLY PRESSURE OUTPUT PRESSURE

STEADY STATE

FLOW RATE

(1)

Bar Psi Bar Psi m

3

/hr Scfh

1.4 20

0.2 - 1.0 3 - 15

0.2 3 0.04 1.5

0.62 9 0.06 2.0

1.0 15 0.07 2.6

2.4 35

0.4 - 2.0 6 - 30

0.4 6 0.05 1.7

1.2 18 0.08 2.9

2 30 0.12 4.1

2.6 38

0.1 - 2.3 2 - 33

0.1 2 0.04 1.5

1.2 17.5 0.08 2.9

2.3 33 0.12 4.3

1. Normal m3/hour - Normal cubic meters per hour (0C and 1.0135 bar, absolute).

Scfh - Standard cubic feet per hour (60F and 14.7psig).

Table 4. Maximum Steady-State Flow Rate

(Natural Gas)

SUPPLY PRESSURE OUTPUT PRESSURE

STEADY STATE

FLOW RATE

(1,2)

Bar Psi Bar Psi m

3

/hr Scfh

1.4 20

0.2 - 1.0 3 - 15

0.2 3 0.06 1.95

0.62 9 0.07 2.6

1.0 15 0.1 3.38

2.4 35

0.4 - 2.0 6 - 30

0.4 6 0.6 2.21

1.2 18 0.11 3.77

2 30 0.15 5.33

2.6 38

0.1 - 2.3 2 - 33

0.1 2 0.06 1.94

1.2 17.5 0.11 3.74

2.3 33 0.18 5.55

1. Normal m3/hour - Normal cubic meters per hour (0C and 1.0135 bar, absolute).

Scfh - Standard cubic feet per hour (60F and 14.7psig).

2. Natural gas steady state flow based on natural gas specific gravity of 0.6.

Flow decreases as specific gravity increases.

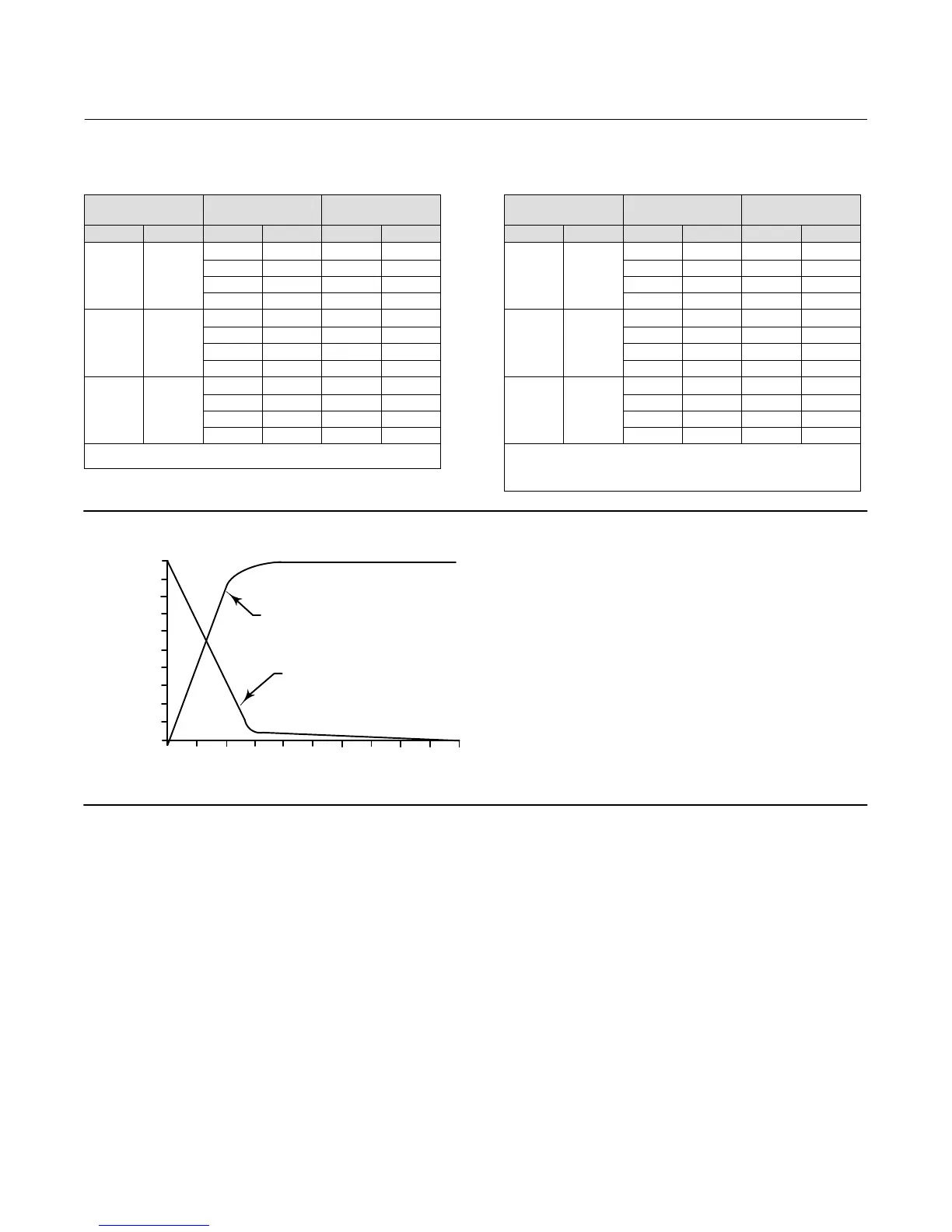

Figure 2. Output‐Time Relationships for Fisher i2P‐100 Transducer

LOADING

EXHAUSTING

TIME (%)

0 102030405060708090

100

0

10

20

30

40

50

60

70

80

90

100

OUTPUT

A6815

(% OF i2P‐100 OUTPUT SPAN)

Installation

The i2P‐100 transducer has been designed and approved for use with either air or natural gas as the supply medium. If

using natural gas as the pneumatic supply medium, natural gas will be used in the pneumatic output connections of

the transducer to any connected equipment. In normal operation the unit will vent the supply medium into the

surrounding atmosphere unless it is remotely vented. When using natural gas as the supply medium, in a

non‐hazardous location in a confined area, remote venting of the unit is required. Failure to do so could result in

personal injury, property damage, and area re‐classification. For hazardous locations remote venting of the unit may

be required, depending upon the area classification, and as specified by the requirements of local, regional, and

federal codes, rules and regulations. Failure to do so when necessary could result in personal injury, property damage,

and area re‐classification.

Additional information for installation and safe use in hazardous locations can be found in Hazardous Area

Classifications and Special Instructions for “Safe Use” and Installation in Hazardous Locations.

Loading...

Loading...