Instruction Manual

D103198X012

i2P-100 Transducer

July 2014

16

For intrinsically safe areas, current monitoring during operation must be with a meter approved for use in hazardous areas.

Equipment Required

Choose a current or voltage source that is capable, without switching ranges, of driving the transducer through its

entire input range. Switching ranges on a current or voltage source will produce spikes or mid‐scale reverses in the

input signal presented to the transducer, causing errors. The current source should be capable of delivering 30 mA

with 30 VDC maximum compliance voltage.

Calibration Procedure

WARNING

To avoid personal injury or property damage due to an uncontrolled process provide some temporary means of process

control before beginning the calibration procedure.

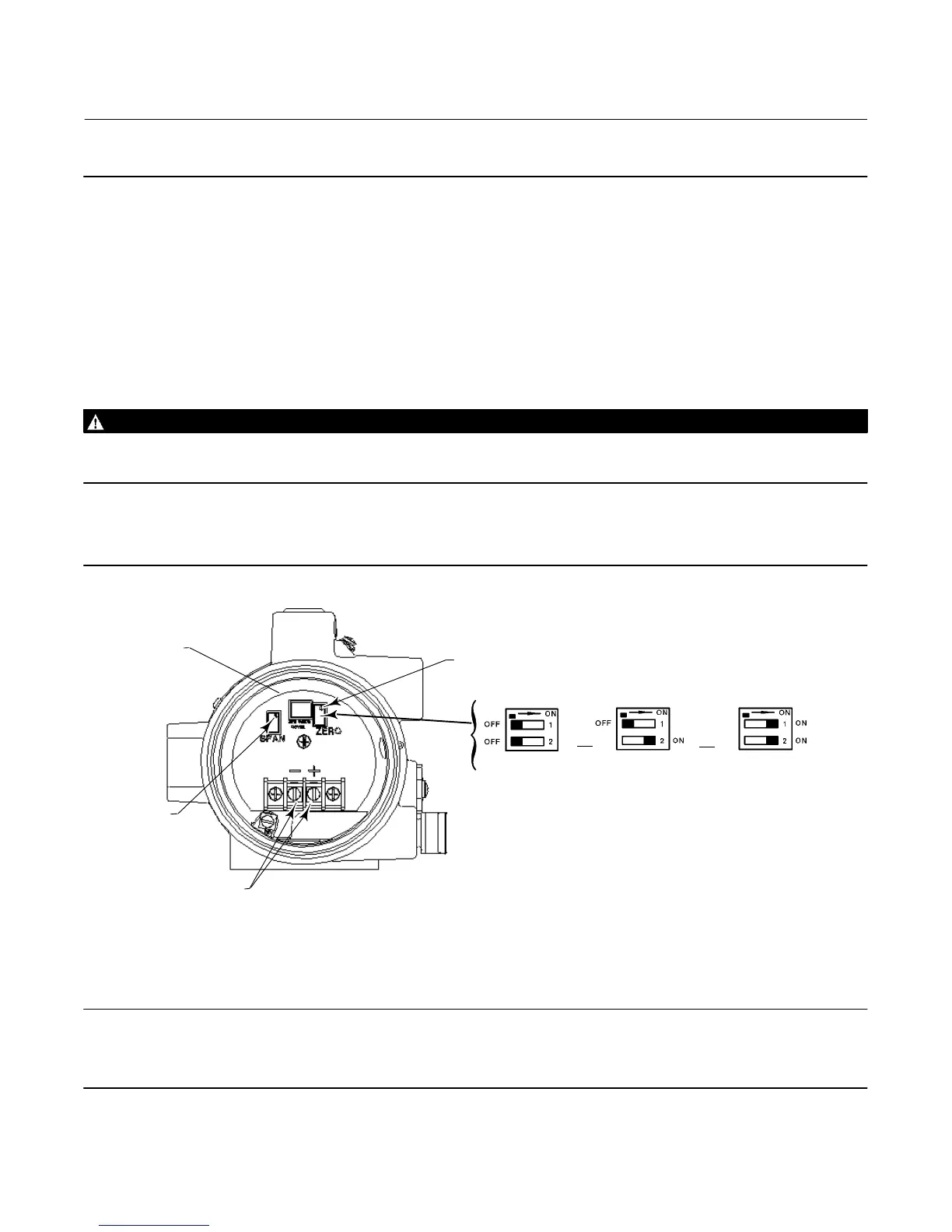

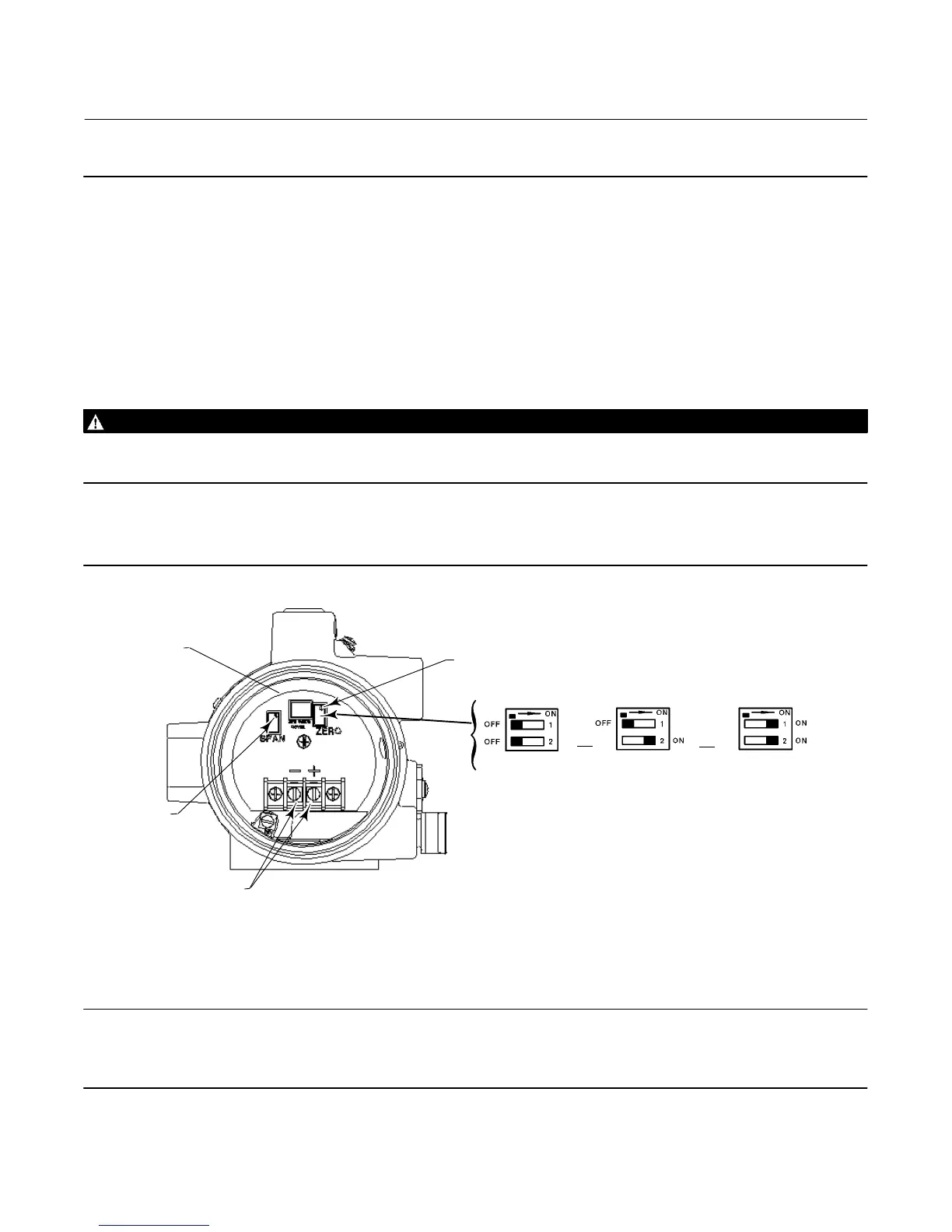

Refer to figure 10 for adjustment locations.

Figure 10. Zero and Span Adjustments and Switch Settings

PCB/CUP

ASSEMBLY

SPAN

ADJUSTMENT

FIELD WIRING

CONNECTION

SWITCH SETTINGS

(3)

ZERO

ADJUSTMENT

4‐20 mA3‐15 psi

4‐12 mA3‐15 psi

OR

4‐20 mA6‐30 psi

OR

4‐20 mA2‐33 psi

12‐20 mA3‐15 psi

{

- +

GE03345

OR

OR

NOTES:

THE SWITCH SETTINGS WILL PRODUCE THE PERFORMANCE CHARACTERISTICS AS INDICATED. FOR

EXAMPLE, BOTH SWITCHES PLACED IN THE OFF POSITION WILL CREATE A 4‐20 mA INPUT WITH A

3‐15 PSIG OUTPUT PERFORMANCE CHARACTERISTIC

1. INPUT SIGNAL SPLIT RANGE IS SELECTABLE VIA DIP‐SWITCH CONFIGURATION.

2. OUTPUT RANGE DIP‐SWITCH SELECTION FOR 0.14 TO 2.0 BAR (2 TO 33 PSIG) USES SETTING B

AND REQUIRES ZERO TO SPAN ADJUSTMENTS. FOR OTHER RANGES, ZERO AND SPAN ADJUST

MENTS NEEDED.

3. SWITCH 1 SET TO THE ON POSITION AND SWITCH 2 SET TO THE OFF POSITION IS NOT A VALID

SWITCH SETTING.

SETTING A

SETTING B

(1,2)

SETTING C

(1)

Note

The following steps are for a 4‐20 mA, 0.2 to 1.0 bar (3 to 15 psig) configured unit. The same procedure is used for other

configurations.

Loading...

Loading...