5

MAT BLADES

The bevel cutting side of the Cutting Head accepts any of three different Fletcher Mat Blades. The 05-012 is .012”

(.3mm) thick and is used for cutting regular mats. The 05-015 is .015” (.4mm) thick and is used for denser or thicker

mats. The 05-016 is a single edge blade, beveled on one side only. It is used for very dense or thick mats and must be

installed with the beveled edge away from the head.

The straight sizing blade on the right is the Utility Blade, 05-004, and is capable of cutting material up to a nominal

1/2” (12mm) thick. All blades except the 05-016 single edge blade can be reversed in their magazine to double the life of

the blade, however, they must be inserted carefully

to avoid damage.

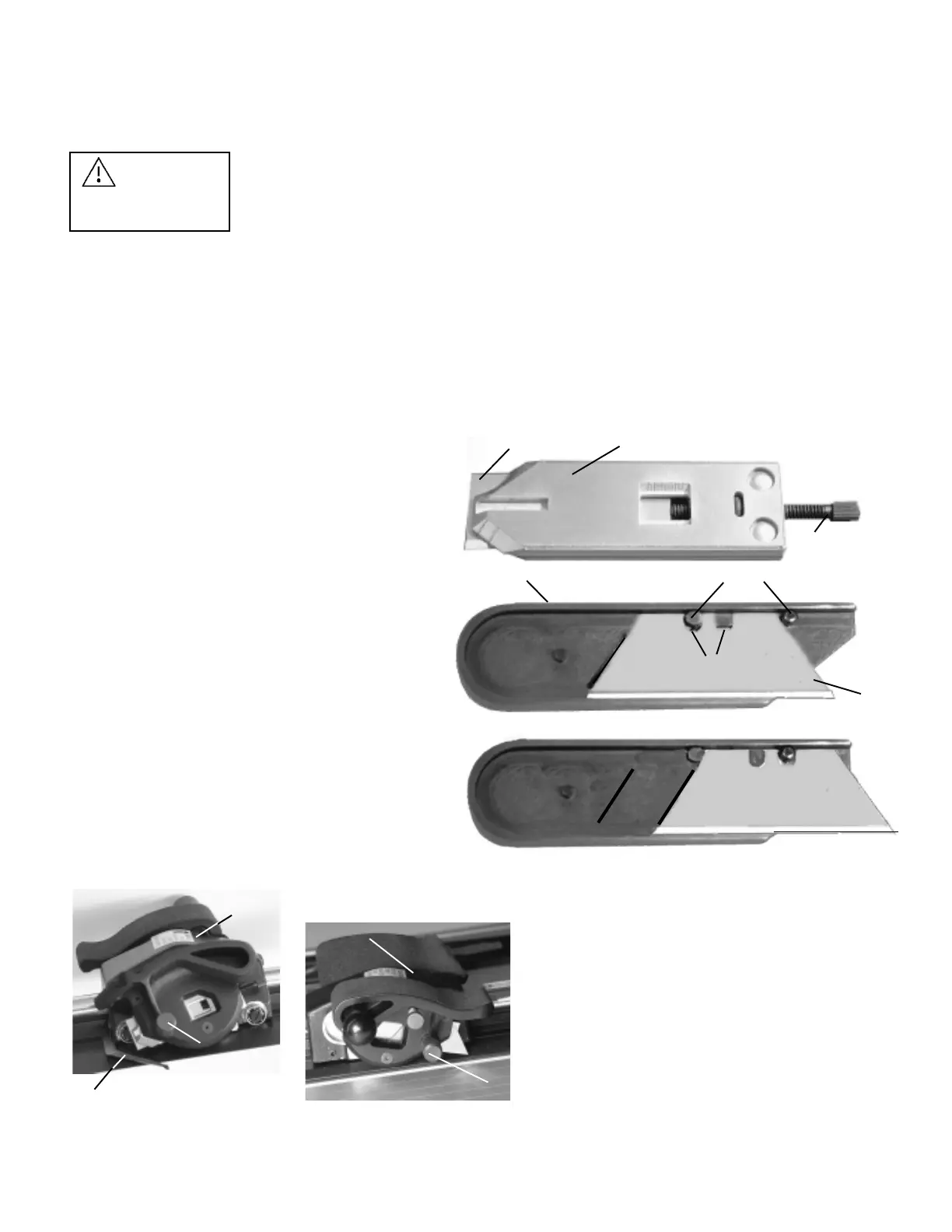

1. Insert a Blade (C) in the bevel cutting Magazine

(A) as shown in Figure 1. The Blade Extension

Screw (B) should be adjusted so the Blade (C)

penetrates about 1/3rd the thickness of a slip

sheet under the mat being cut. The blade should

always rest against the Blade Extension Screw

(B), and the Magazine (A) must be fully inserted

in the Cutting Head (D). Tighten its Locking

Knob (E) firmly. See Figure 3.

2. Straight cutting (sizing) is done on the right side

of the Cutting Head (D). The Magazine (F) and

Utility Blade (G), (05-004), are shown in Figure 2.

There are 4 possible depth positions for this blade,

but only two are used as seen in Figures 2 and 2a.

Figure 2a is the position for nominal 1/2” (12mm)

material, while Figure 2 is for 2, 4, 6, and 8 ply mat

board. The blade is held in place by a magnet. Insert

the Magazine (F) to a stop in the Cutting Head (D)

and tighten its Locking Knob (K). See Figure 4.

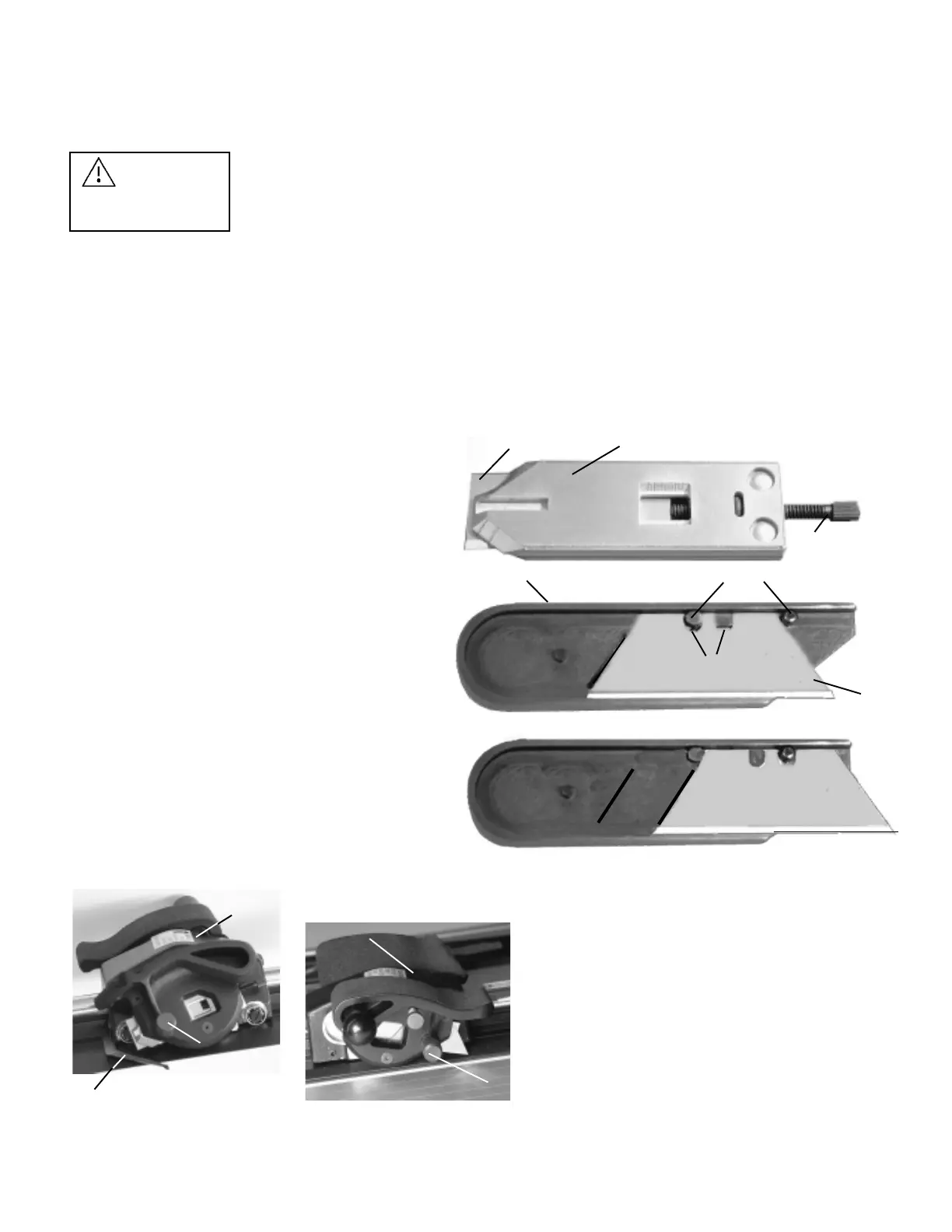

3. The Sight Gage (L) shown in Figure 3 is used to control the start of cut and end of cut when using pencil lines drawn

on the back of the mat. It is held in place on the Cutting Head with a magnet and can

be removed and set aside when not being used. The

use of this feature is explained on the following page.

CAUTION:

SET UP

Place nine self adhesive rubber bumpers from the parts bag equally spaced on the bottom of the Base to prevent

scratching a table top. Set the Fletcher 2200 on a flat table with the Clamp Handle to the left.

Figure 1

A

Figure 2a

F

H

E

F

J

C

D

Figure 3

Figure 4

D

B

USE EXTREME CARE

HANDLING BLADES.

THEY ARE VERY SHARP

G

K

L

Figure 2

D

68

“Ganchos” en La cuchilla se proyecta Ajuste la proyección MONTAJE

los cortes demasiado lejos de la cuchilla

Cabezal flojo Ajuste los rodamientos MANTENIMIENTO

del cabezal

El cabezal El paso del rodamiento Limpie el gancho de MANTENIMIENTO

hace ruido a rodillo está sucio passe-partout

Los rodamientos a rodillo Quite el cabezal y MANTENIMIENTO

están sucios limpie los rodamientos

Use cinta para quitar MANTENIMIENTO

material extraño

PUEDE RECIBIR AYUDA PONIÉNDOSE EN CONTACTO CON SU DISTRIBUIDOR DE FLETCHER-TERRY

O CON EL SERVICIO AL CLIENTE DE FLETCHER-TERRY C AL 860.677.7331

customerservice@fletcher-terry.com.

GUÍA DE SOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSA POSIBLE CORRECCIÓN REFERENCIA

Cortes en bisel Cuchilla desafilada Cámbiela por una cuchilla nueva MONTAJE

deshilachados

Hoja gastada Use una hoja nueva CÓMO CORTAR

PASSE-PARTOUT

No corta a través Proyección de la cuchilla Extienda la proyección MONTAJE

del passe-partout de la cuchilla

Cuchilla gastada o rota Reemplace la cuchilla MONTAJE

Demasiada presión sobre Libere la presión CÓMO CORTAR

el asa PASSE-PARTOUT

Demasiados cortes Proyección de la cuchilla Ajuste la proyección MONTAJE

en exceso de la cuchilla

Paradas de medida Ajuste las paradas de medida CÓMO CORTAR

PASSE-PARTOUT

Cortes en defecto Proyección de la cuchilla Ajuste la proyección MONTAJE

de la cuchilla

Paradas de medida Ajuste las paradas de medida CÓMO CORTAR

PASSE-PARTOUT

El cabezal Rodamientos del cabezal Ajuste los rodamientos MANTENIMIENTO

se bloquea del cabezal

El cabezal está Rodamientos del cabezal Ajuste los rodamientos MANTENIMIENTO

demasiado flojo del cabezal

Loading...

Loading...