44

SMS 305 18-EC

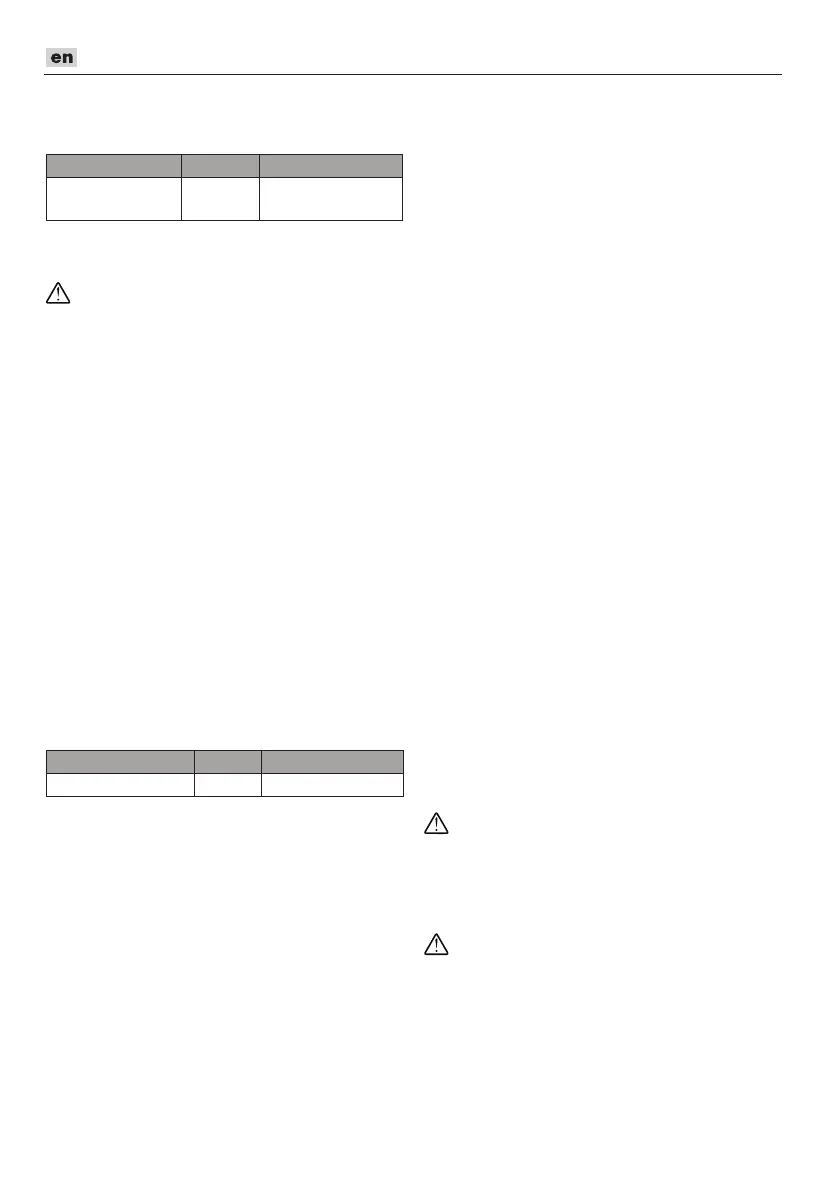

The table can be latched at these miter-

detent slots (L-1).

Detent position

Left Middle Right

45°; 31.6°;

22.5°; 15°

0°

15°; 22.5°; 31.6°;

45°; 60°

Adjusting bevel angle (see figure

M)

WARNING!

After each adjustment of the angle for a bevel

cut, always check that the saw blade has

clearance.

Unlock the bevel lock lever (14) by lifting it

up to the Bevel Unlocked Position (M-2)

or until you feel that the saw head can be

tilted.

Tilt the saw until the bevel-angle indicator

(29) points to the desired angle on the

bevel scale plate (28).

Lock the bevel lock lever (14) by pressing

it down to the Bevel Locked Position

(M-3).

For quick, accurate selection of the

commonly used inclination angles, the

saw head can be latched at any of several

positions. Tilt the saw head until the bevel-

detent pin completely snapped into

the bevel-detent slot. A click sound that

indicates the override function is engaged.

To disengage, lift the bevel lock lever (14)

to the Bevel Override Position (M-1).

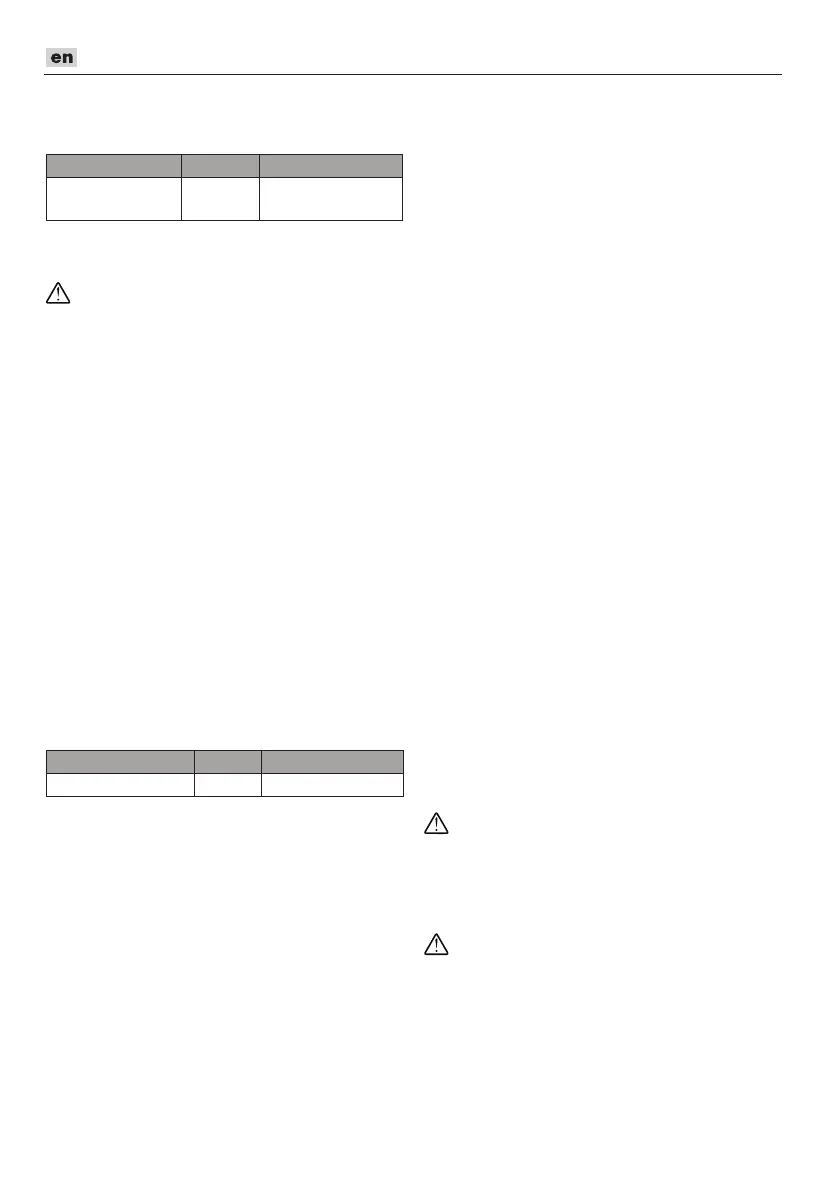

Detent positions

Left Middle Right

45°; 33.9°; 22.5° 0° 22.5°; 33.9°; 45°

Unlocking/locking the saw arm

(see figure N)

To unlock and raise the saw arm (Working

Position):

Firmly grasp the main handle (1) and apply

downward pressure while at the same time

pulling the arm-lock pin (5) out so that it

stops in unlock position.

Slowly raise the saw arm.

To lock the saw arm (Transport Position):

Firmly grasp the main handle (1) and apply

downward pressure until head stops.

Push in the arm-lock pin (5) toward the

saw, allowing it to lock the saw into place.

Slide-rail lock knob (see figure O)

Loosen the slide-rail lock knob (4) to

slide the saw head through the sliding

mechanism forward or backward to the

desired position.

Be sure to tighten the slide-rail lock knob

(4) after the desired position is reached.

Setting cutting depth (see figure

P)

The depth stop is a feature provided to allow

for (normal) full-depth cuts or non-through

cuts used to cut grooves.

Remove the battery.

Make sure the arm-lock pin (5) is

disengaged.

Press the depth stop plate (22) down.

Grip the main handle (1) and push the saw

head down while watching the depth stop

bolt (23) contact the surface of the depth

stop plate (22).

Rotate the bolt (23) and watch the bottom

of the saw blade move. This adjustment

sets the depth of cut.

When making normal, full-depth cuts, push

the depth stop plate (22) up and the bolt

(23) pass through the depth stop plate (22)

without any binding or contact with the

plate.

Sli

ding fences (s

ee figure Q)

Loosen the sliding fence lock knob

(24) at each side by rotating the knob

counterclockwise, then slide the fences (6) in

or out to install or remove them.

When the desired position of the sliding

fences (6) is reached, tighten the lock knob

(24) by rotating the knob clockwise.

WARNING!

Before operating the tool, make sure that

the sliding fences (6) are secured firmly.

Long workpiece support (see

figure R1-R2)

WARNING!

Long workpieces have a tendency to tip

over unless clamped down and properly

supported from underneath.

Loading...

Loading...