7

Flexzilla Electric Operated, Oil-Free Portable Air Compressors

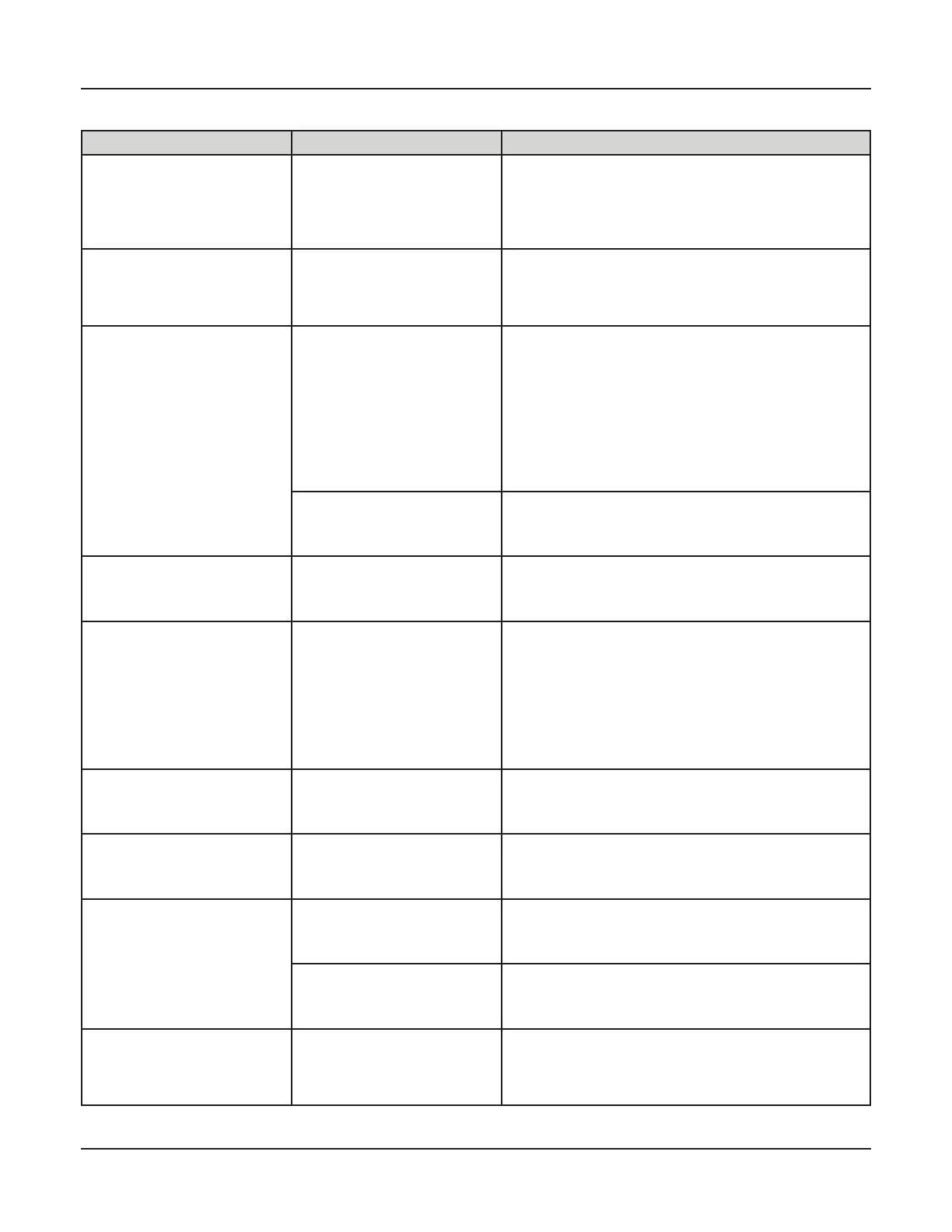

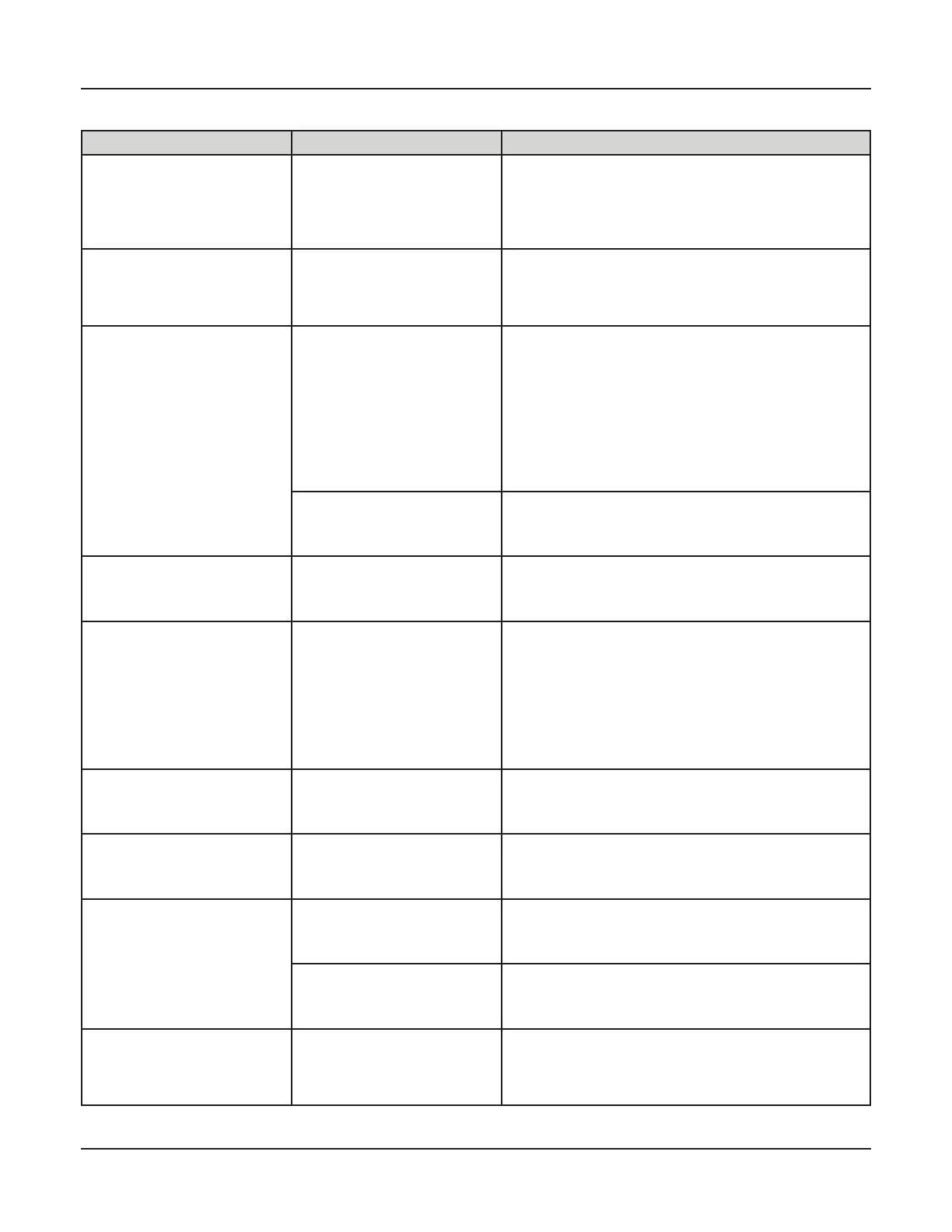

5. TROUBLESHOOTING

Problem Possible Cause Repair

Pressure drop in the tank. Air leaks at connecons. Let the compressor build pressure in the tank, to the

maximum pressure if possible. Brush soapy water on air

connecons and look carefully for air bubbles. Tighten

leaky connecons. If the problem persists, contact

Customer Support for further advice.

The unloader valve leaks when

the compressor is idle.

Unloader valve seal is defecve. Let the air in the air tank ow out unl all the pressure is

released. Then remove the unloader valve plug and clean

the valve seal. If necessary, replace the seal and then

reinstall all components.

The compressor stopped and

does not start.

The thermal protecon turned

on because the motor is

overheang.

Check that the main voltage corresponds to the air

compressor specicaons. An extension cord that is too

thin or too long can cause a voltage drop and cause the

motor to overheat.

Excessive use (over 1 hour connuous use) can cause the

motor to overheat.

Allow the motor to cool down.

Motor windings are burned out. Contact Customer Support.

The motor does not start and

makes a humming noise.

Capacitor is burned out. Contact Customer Support.

The motor does not start or

starts slowly.

Low voltage supply to the motor. Check that the main voltage corresponds to the air

compressor specicaons.

An extension cord that is too thin or too long can cause a

voltage drop. Use heavy duty extension cords.

Ensure that the air compressor is plugged into a fully

funconal power outlet.

The compressor is noisy with

metallic clangs.

Compressor head gasket or reed

valve is damaged.

Stop the compressor and contact Customer Support.

The compressor does not reach

the maximum pressure.

Compressor head gasket or reed

valve is damaged.

Stop the compressor and contact Customer Support.

The compressor doesn’t seem

to provide as much air as it

did when new and/or the

compressor cuts o within a

much shorter me period.

The pressure switch needs

adjusng.

Stop the compressor and contact Customer Support.

The tank is full of water due to

condensaon.

Open the drain valve and release the water from the tank.

The motor pump unit does not

stop when the tank pressure

reaches its maximum working

pressure.

Pressure switch is defecve or

needs adjusng.

Stop the compressor immediately and contact Customer

Support.

Loading...

Loading...