5 –Camera Controller

A6000 and A8500 Series User’s Manual

51

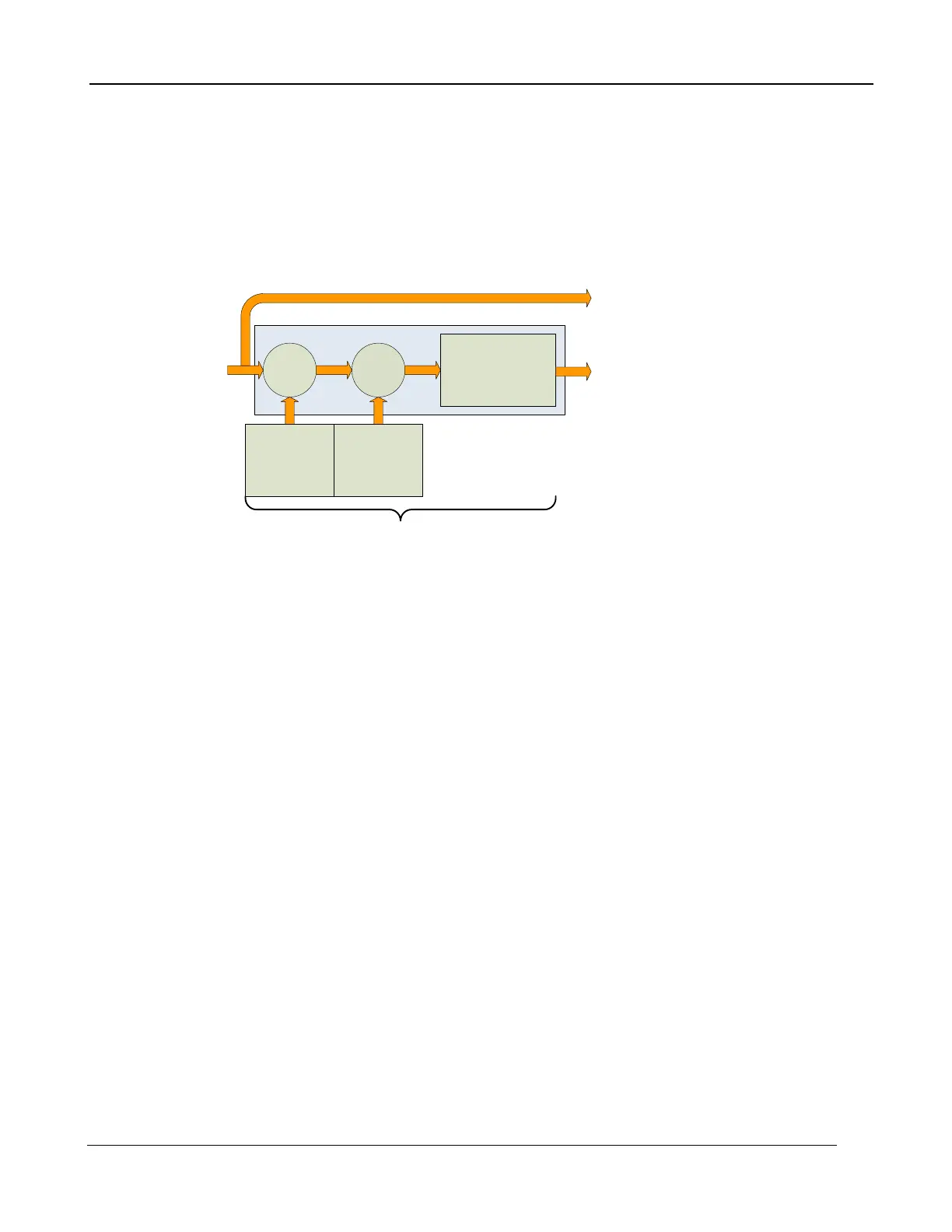

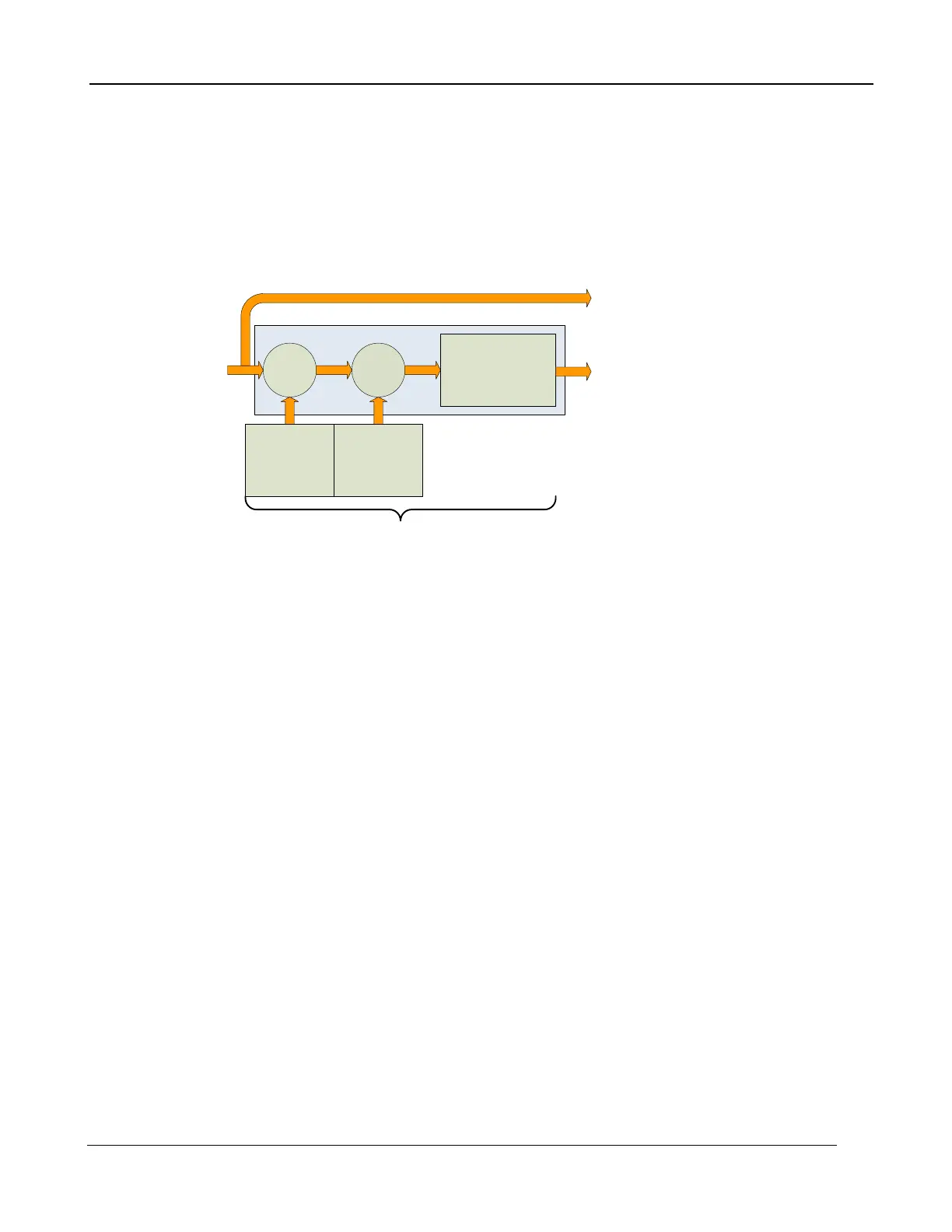

5.5.5.1.1 Two-Point Correction Process

The Two-Point Correction Process builds a NUC table that contains an individually computed gain

and offset coefficient for each pixel as seen in Figure 4-14. Two uniform sources are required for this

correction. One source at the low end and a second source at the upper end of the usable detector

input range. Because of the use of two images at either end of the input range, the Two-Point

Correction yields better correction results. A two-point correct will also work better over a wider range

of scene temperatures.

Figure 4-14: Two-Point Correction

5.5.5.1.2 Offset Update

Often during the normal operation of a camera, the electronics and/or optics will heat up or cool down

which changes the uniformity of the camera image. This change requires a new NUC. However, this

change is mainly in the offset response of the image while the gain component stays constant. An

Offset Update simply computes a new offset coefficient using the existing gain coefficient and corrects

the image non-uniformity. Offsets Update are typically performed when a Two-Point NUC table is

being used.

An Offset Update requires only one uniform source, usually set at a temperature on the lower edge of

the operational range.

Loading...

Loading...