4

Information specific to your particular

turbine, including serial number, model

number, manufacturing date, and

K-factor is etched on the meter. Be pre-

pared to provide this information if you

call customer service.

SN = Serial Number, a 6-digit number

that identifies this particular turbine.

MODEL = Model Number, G2 followed

with a letter indicating the housing ma-

terial.

A for Aluminum

S for Stainless Steel

Two digits follow the material code indi-

cating the size.

05 – 1/2 inch

07 – 3/4 inch

10 – 1 inch

15 – 1-1/2 inch

20 – 2 inch

The final letter indicates the type of

thread.

F for Flange

N for NPT

I for ISO

T for Tri-Clover® Flange

MFG DATE = Manufacturing Date in-

dicating the week and year of manufac-

ture.

KF = K-Factor given in pulses per gal-

lon (PPG).

INSTALLATION

For your future reference, it might be

useful to record this information in the

manual in case it becomes unreadable

on the turbine.

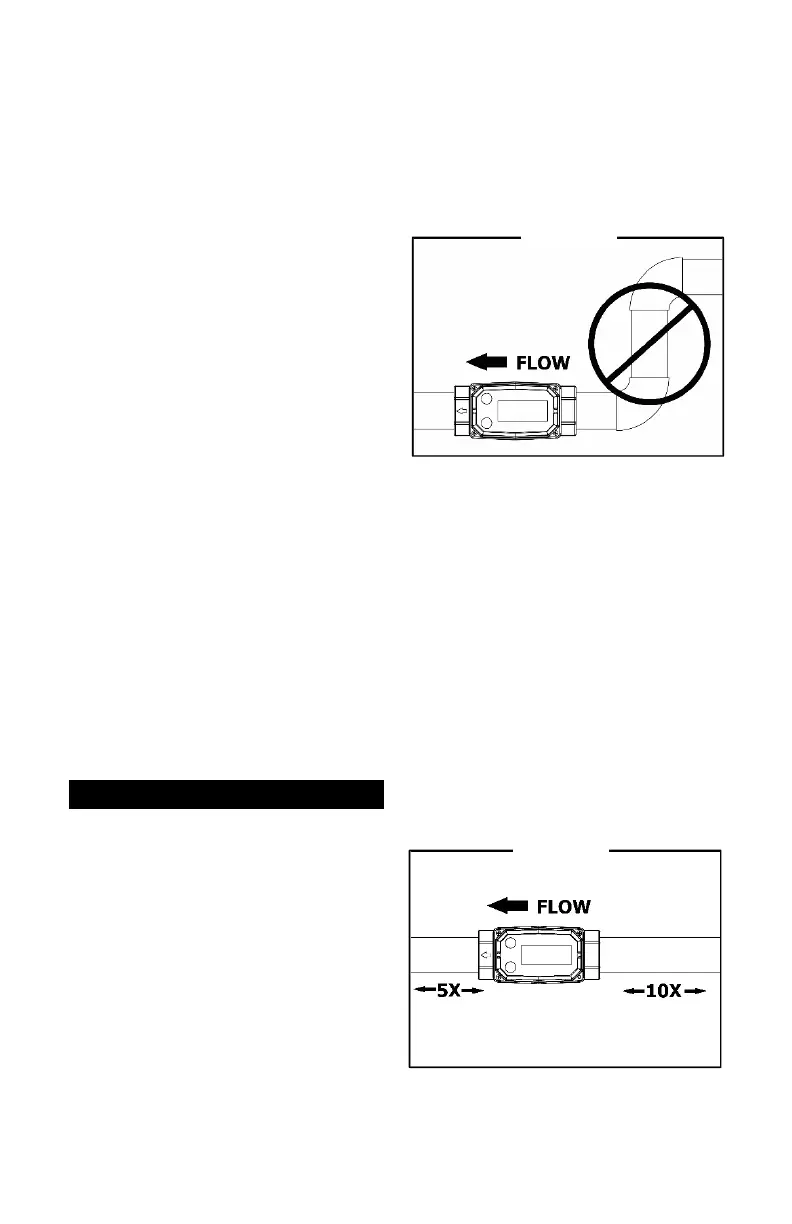

All FLOMEC® turbines are designed to

measure flow in only one direction. The

direction is indicated by the arrow,

cast-molded in the turbine.

Flow altering devices such as elbows,

valves, and reducers can affect accu-

racy. See Diagram 1. The following rec-

ommended guidelines are given to en-

hance accuracy and maximize perfor-

mance. Distances given here are mini-

mum requirements; double them for

desired straight pipe lengths.

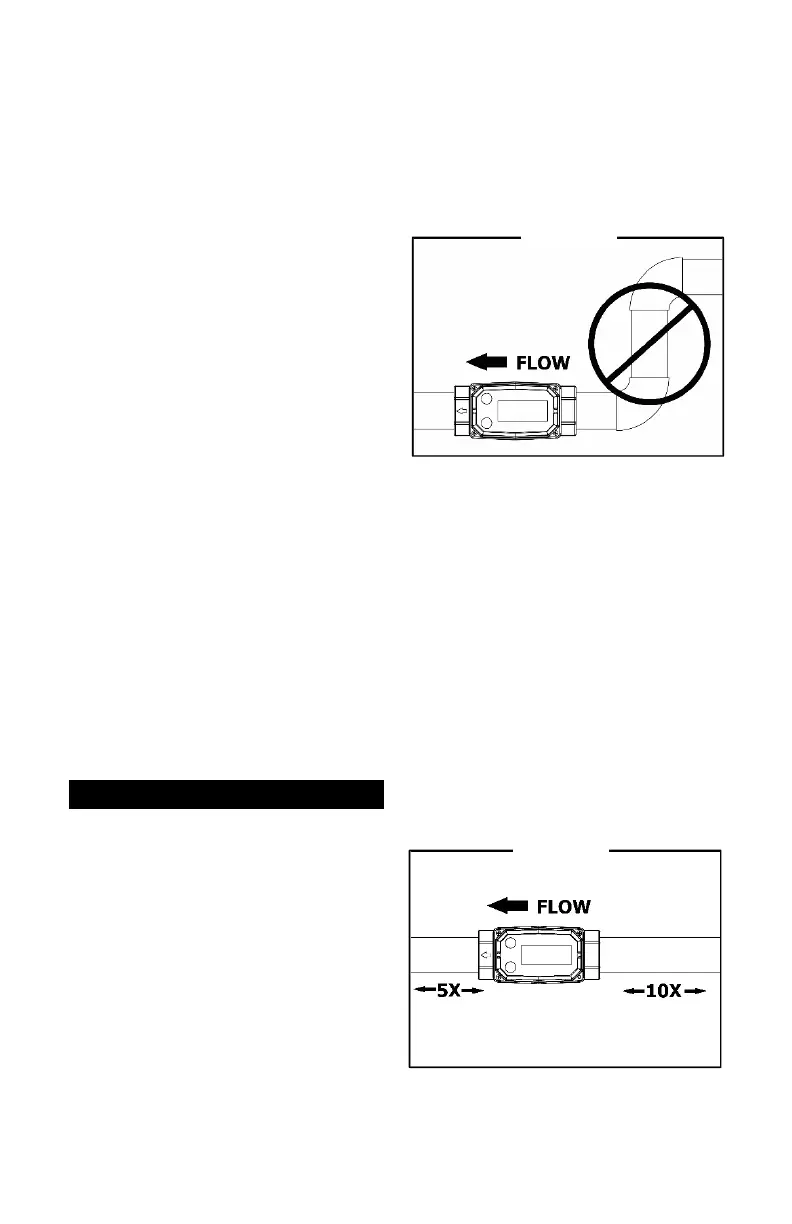

Upstream from the turbine, allow a min-

imum straight pipe length at least 10

times the internal diameter of the tur-

bine. For example, with the 1-inch tur-

bine, there should be 10 inches (25.4

cm) of straight pipe immediately up-

stream. The desired upstream straight

pipe length is 20 inches (50.8 cm).

Downstream from the turbine, allow a

minimum straight pipe length at least 5

times the internal diameter of your tur-

bine. For example, with the 1-inch tur-

bine, there should be 5 inches (12.7

cm) of straight pipe immediately down-

stream. The desired downstream dis-

tance is 10 inches (25.4 cm). See Dia-

gram 2.

Loading...

Loading...