16

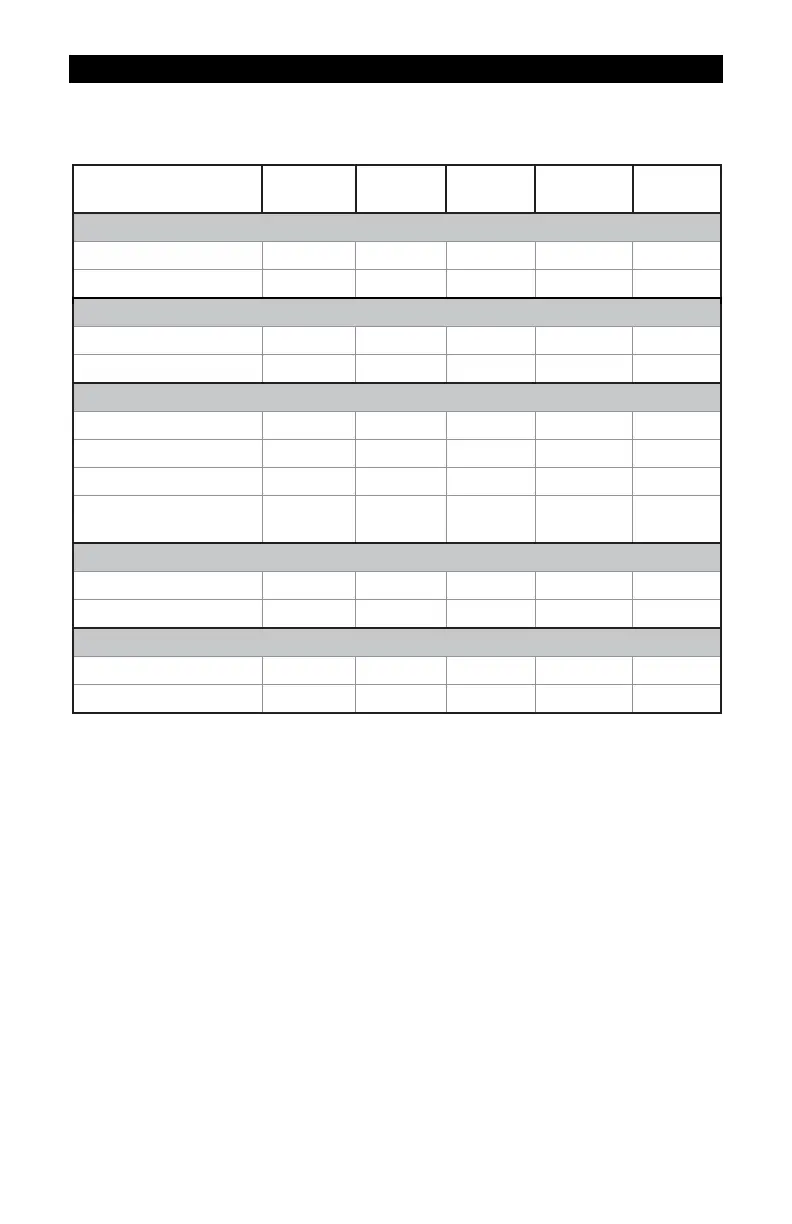

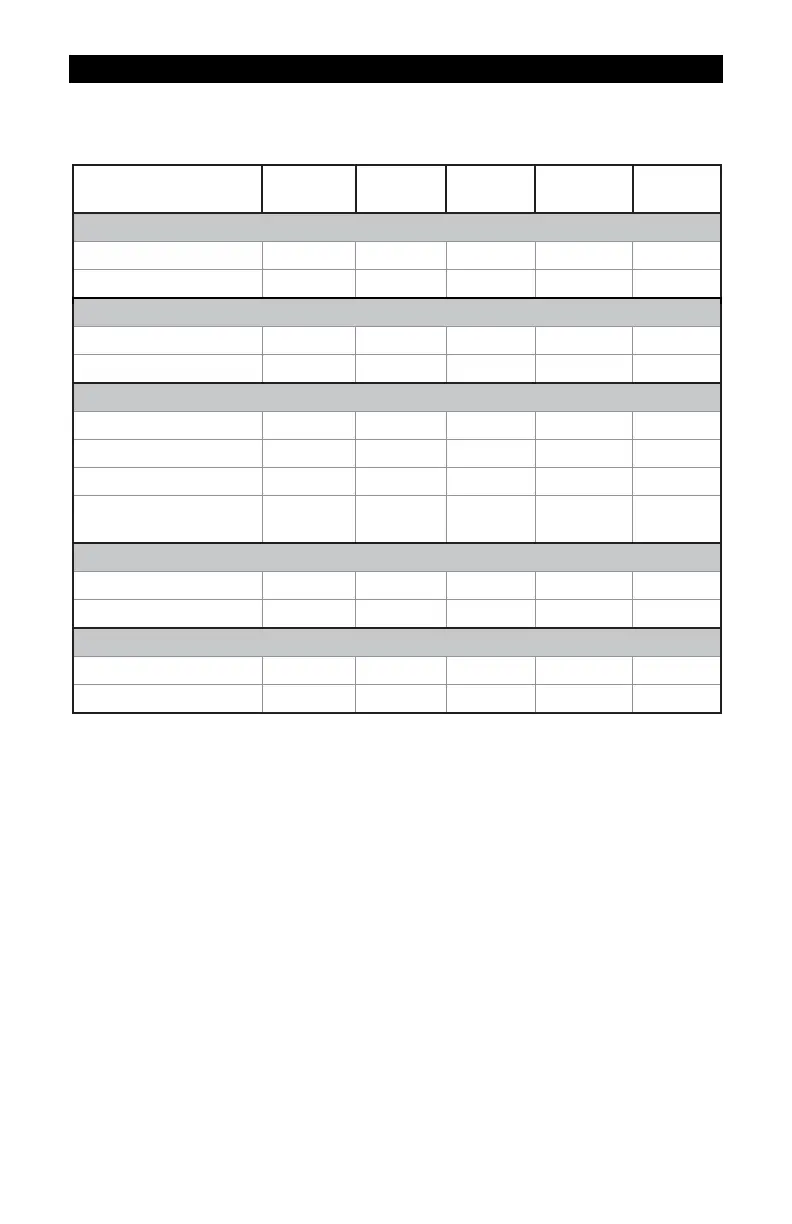

SPECIFICATIONS – TRI-CLOVER® FLANGE FITTINGS

All data on Models 1/2 inch, 3/4 inch and 1 inch determined with 1 centipoise solvent test fluid at

70° F (21° C). Data on Models 1-1/2 inch and 2 inch is determined with water at 70° F (21° C).

Size refers to the size of the turbine, not the body ferrule. Refer to dimension chart for detail sizes.

Model Size

1/2 in.

3/4 in.

1 in.

1

1/2 in.

2 in.

Linear Flow Range

Gallons/minute (GPM) 1-10 2-20 5-50 10-100 20-200

Litres/minute (LPM) 3.8-37.9 7.6-75.7 18.9-190 38-380 76-760

Maximum Flow

Gallons/minute (GPM) 15 30 75 150 300

Litres/minute (LPM) 56.8 113.6 284 568 1,136

Maximum Pressure Drop

in 10:1 Range

PSIG 8 7.5 5 4 4

bar 0.55 0.52 0.34 0.28 0.28

Frequency Range in Lin-

ear Flow Range

45-450 Hz 37-370 Hz

45-475 Hz

35-350 Hz 33-330 Hz

Connections

Inlet/Outlet Size 1/2 in. 3/4 in. 1 in. 1-1/2 in. 2 in.

Fitting Clamp Size 3/4 in. 1 in. 1-1/2 in. 2 in. 2-1/2 in.

Weight*

Pounds 1.1 lbs. 1.6 lbs. 2.1 lbs. 3.9 lbs. 5.7 lbs.

Kilograms 0.5 kg 0.7 kg 1.0 kg 1.8 kg 2.6 kg

* Computer electronics add 0.2 lbs. (0.1kg) to total weight.

1

The meter can operate up to this flowrate without damage. Continuous operation will

severely degrade meter life and performance.

Performance

Linear Range for 1/2 in.: 10:1 @ ±2.0% of reading

Linear Range for 3/4 in. and 1 in.: 10:1 @ ±1.5% of reading

Linear Range for 1-1/2 in. and 2 in.: 10:1 @ ±1.0% of reading

Repeatability: ±0.1%

Pressure Rating 450 PSIG (31 bar) @ 70° F

with Type 1 Buna-N Gasket

Wetted Components

Housing: 316 Stainless Steel

Journal Bearings: Ceramic (96% Alumina)

Shaft: Tungsten Carbide

Rotor and Supports: PVDF

Retaining Rings: 316 Stainless Steel

Temperature Range -40° F to +250° F (-40° C to +121° C)

These temperatures apply to operations and storage. They are only for the turbine

without computer electronics. Final operational temperature range is determined by

computer electronics or accessory modules.

Loading...

Loading...