CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05

Page 15 of 66

®

absolute concentricity with all diametric fits

machined at one setting.

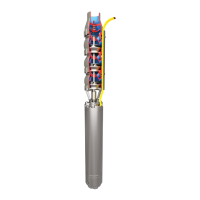

3.3.3 Shaft [2100]

The shaft [2100] furnished is machined from the

highest quality material selected with consideration

to the service for which the pump is to be applied.

The shaft is of sufficient diameter to assure low

torsion stresses and is accurately ground and

polished throughout its entire length.

3.3.4 Sealing - Stuffing box housings [4110.’s]

The stuffing box housings [4110.’s] seal the pump

suction and discharge casings [1130 and 1140] and

shaft [2100] and mounts, at their outboard end, the

bearing housing [3200.’s.].

The stuffing box housings [4110.’s] are designed to

withstand the maximum discharge pressure and

accept either packing [4130] or various mechanical

seals [4200].

The stuffing boxes housings [4110.’s] may be

serviced by removing a minimum of parts and may

be removed without disturbing the suction and

discharge piping, tie bolts [6571], or main pump

bundle.

By using a spacer type coupling [7000] the inboard

stuffing box housing [4110.1] can be removed to

allow the inspection of 1

st

stage impeller [2200.1]

and its casing wear ring [1500.1] clearances.

Water-cooled stuffing box housings [4110.’s] are

used for pumping temperature above 130 °C (266

°F) when fitted with mechanical seal [4200] and

above 100 °C (212 °F) when including packing

[4130].

3.3.5 Impellers and wear rings [2200.’s and

1500.’s]

Individually mounted impellers [2200.’s], of one-

piece construction, are keyed to the shaft with

keyways, as standard, on alternate sides of the shaft

[2100]. The 1st stage impeller [2200.1] is positioned

against a shoulder on the shaft [2100] with the

remaining impellers [2200.2] stacked hub to hub.

During operation, force is transmitted through the

impeller [2200.’s] hub into the shaft [2100] at the

shaft [2100] shoulder.

Renewable casing wear rings [1500.’s] are provided

to control leakage past the impeller [2200.’s] hubs.

3.3.6 Discharge casing [1140]

The discharge casing [1140] is the exit port of the

pump, directs the fluid from the last stage diffuser

[1410.2] to the pipe-work and incorporates the

discharge nozzle and its flange. The discharge

casing [1140] closes the discharge end of the casing

and mounts the outboard end stuffing box housing

[4110.2]. The pump outboard end feet and drilling to

receive the pump tie bolts [6571] are also

incorporated into the discharge casing [1140].

3.3.7 Balancing device [6210 and 6220]

Flowserve ring section pumps are maintained in

complete axial balance during operation by a self-

compensating flanged balance disc [6210], and

counter balance disc [6220]. The balancing device

assembly located at the discharge end effectively

counteracts the normal axial thrust developed by the

rotor toward the suction end of the pump. The front

end of the balance disc [6210] is exposed to full

discharge pressure. The chamber at the back of the

balance disc [6210] is piped to suction pressure,

placing this pressure on the outer face. A thrust is

therefore developed which is equal in magnitude

and opposite in direction to the normal thrust of the

pump impellers [1500.’s] toward the suction.

The pump design allows renewing the balancing

device [6210 and 6220] in the field, without

disturbing the pipe-work, the tie bolts [6571] or the

main pump bundle.

3.3.8 Bearings [3012.’s]

The bearings [3012’.s] are of the antifriction roller

radial type and have grease lubrication as standard

with optional oil lubrication.

In units fitted with optional rotor setting spring [4260]

the non-drive end includes, in addition to the roller

type bearing, an antifriction single row angular

contact balls bearing [3011].

3.3.9 Pump pedestals

The pump should not be removed from the pedestal

unless it is going to be disassembled. The pump

pedestal help to keep the suction and discharge

nozzles aligned while tightening the tie bolts [6571].

3.4 Performance and operating limits

This product has been selected to meet the

specifications of your purchase order; see 1.5.

Loading...

Loading...