CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05

Page 20 of 66

®

4.8.3.2 Before alignment

It is recommended that the pump hold

down bolting be torqued and the pump be fixed

before taking any alignment measurements. This

makes the driver [8000] the movable machine. In

certain cases, however, it may be impractical to

move the driver [8000]; therefore, the pump may

have to be moved. When this case exists, the pump

should not be fixed until after final alignment. (See

Doweling Pump and Driver [8000]).

If pump shaft [2100] must be rotated

bearings [3012.’s] and when fitted [3011] are to be

pre-lubed before aligning starts; see 5.3

Align pump and driver [8000] using the rim and face

method, rotating driver [8000] only. Align equipment

such that coupling [7000] hub rims are aligned within

0.050 mm TIR (0.002 in. TIR), and coupling [7000]

hub faces are parallel within 0.025 mm (0.001 in.).

Refer to "RIM AND FACE DATA SHEET";

see 4.11.

Laser alignment, double reverse (dial) alignment, or

reverse rim (dial) alignment methods can be used to

check alignment when site requirements dictate.

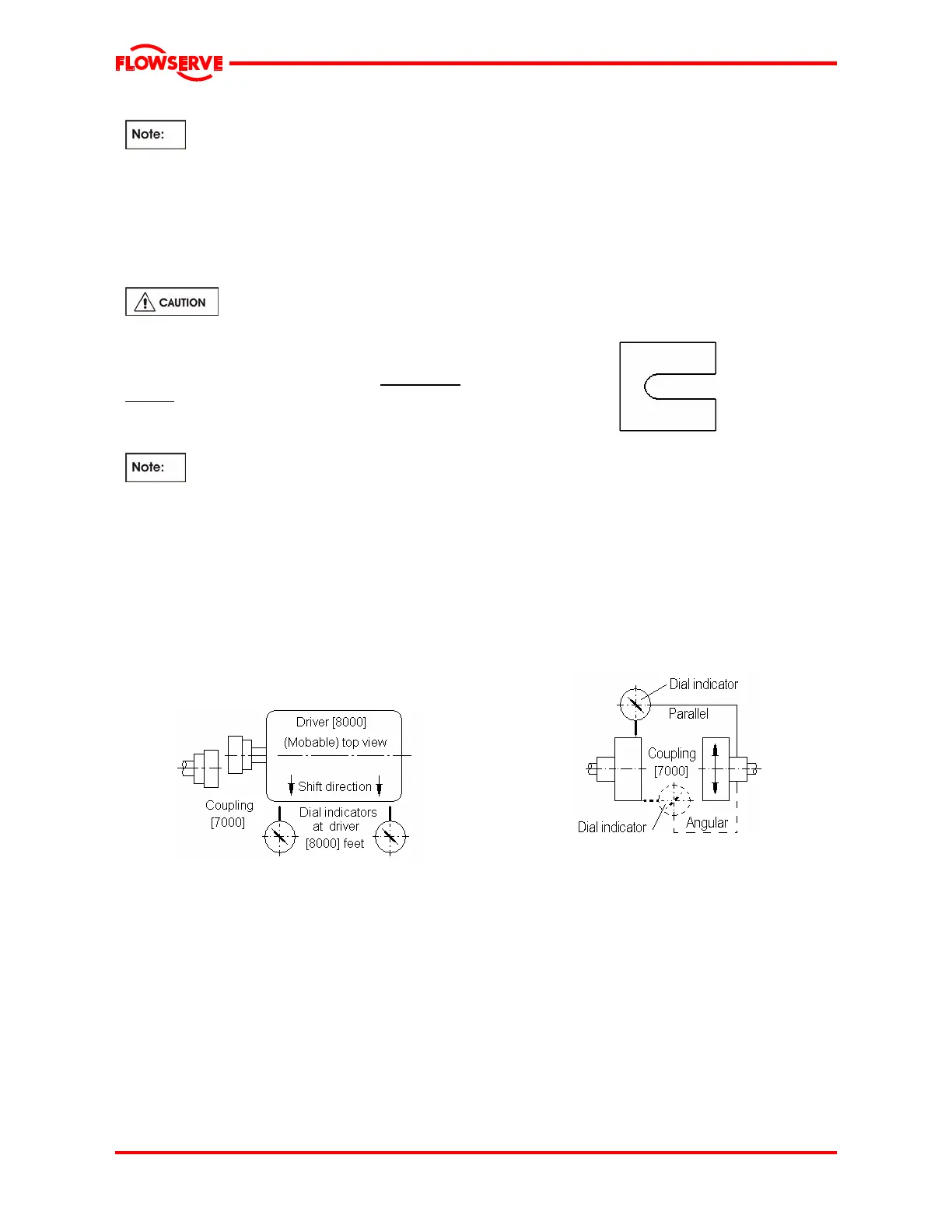

4.8.3.3 Horizontal move

The dial indicators shown below are required to

accurately measure the move in the horizontal

direction. Move the driver [8000] by bumping with

soft hammer/mallet or using the alignment screws (if

provided).

Fig.8 Horizontal Move

4.8.3.4 Vertical move

Before moving the equipment vertically, it is

important that the vertical thermal expansion be

taken into consideration.

Refer to General Arrangement drawing Notes

if any and/or Driver [8000] Instructions for

recommended cold vertical setting.

The stainless steel shims between the equipment

feet and mounting surface should be clean and dry.

This is especially critical for pumps that have been in

service for some time and need to be realigned.

Water, dirt and rust may change the height of the

shim pack over a period of time. Shims should be

made large enough to support the weight of the

equipment on its mounting foot. Do not use many

thin shims, as this may result in a spongy mounting.

Move the equipment vertically by adding or removing

the calculated thickness of shims. Torque equipment

hold-down bolting to required values.

Fig.9 Recommended shim design

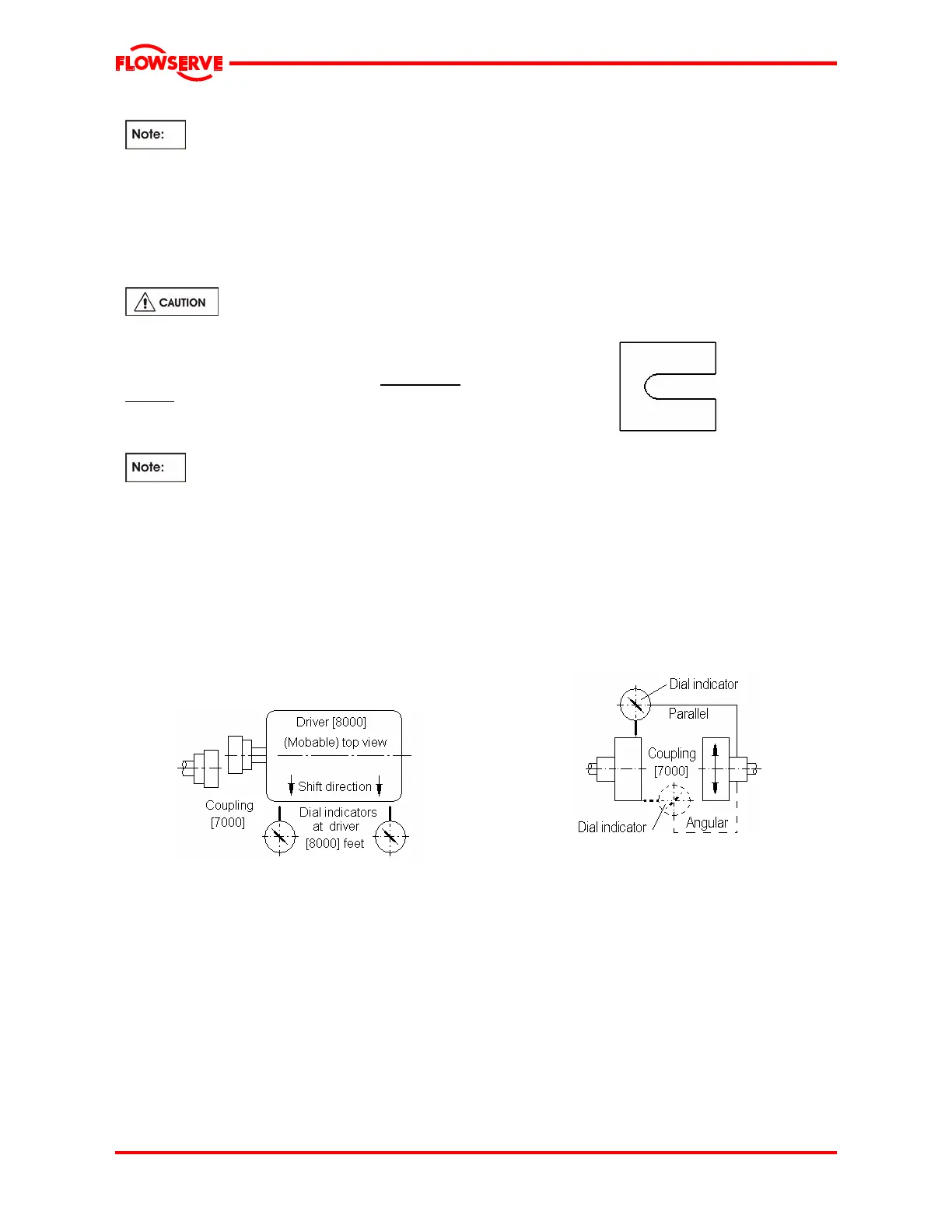

4.9 Checking coupling [7000] alignment

The angular and offset coupling [7000] alignment

must now be rechecked:

• Coupling [7000] faces are to be parallel within

0.025 mm (0.001 in.)

• Coupling [7000] outside diameters are to be

aligned within 0.050 mm TIR (0.002 in. TIR)

Use a dial indicator as in Fig.10 to check both

parallel and angular alignment.

Fig.10 Checking coupling [7000] alignment

"Bump" the driver [8000] and check driver [8000]

rotation.

4.10 Assembling coupling [7000]

Assemble the coupling [7000] (s) per the

manufacturer's instructions.

Install coupling [7000] guard(s).

Loading...

Loading...