CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05

Page 19 of 66

®

Shafts alignment must be correct for

successful operation. Rapid wear, noise, vibration

and actual damage to the equipment may be caused

by shafts misalignment. The shafts must be aligned

within the limits given within this section.

Adjustment to correct the alignment in one

direction may alter the alignment in another direction.

Always check in all directions after making any

adjustment.

Coupled equipment must be aligned to minimize

unnecessary stresses in shafts, bearings and

coupling [7000]. Flexible couplings [7000] will not

compensate for appreciable misalignment.

Foundation settling, thermal expansion or nozzle

loads resulting in foundation deflection and vibration

during operation may require the full coupling [7000]

misalignment capability.

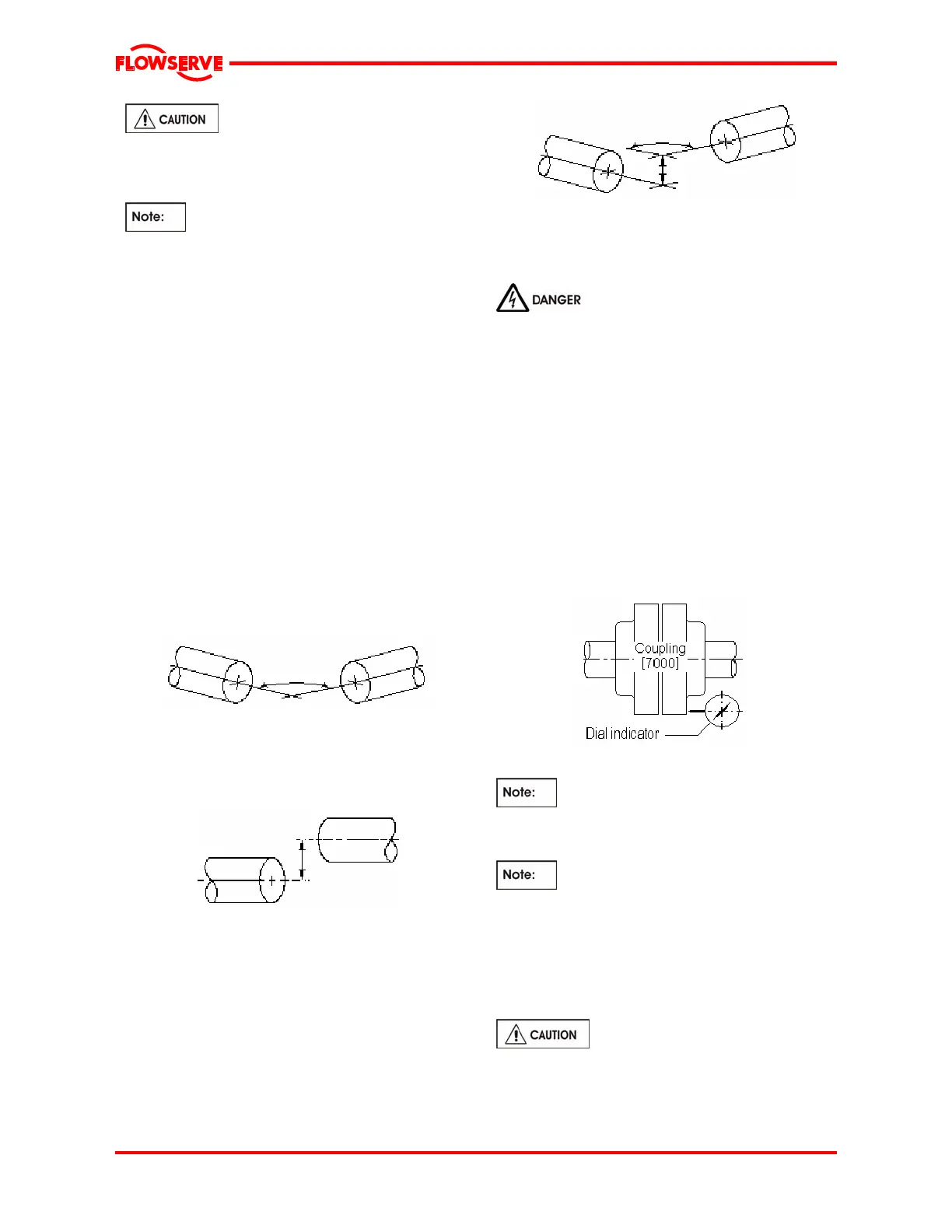

4.8.2 Types of misalignment

There are two types of shafts misalignment: Angular

and Offset. Therefore, two sets of measurements

and corrections are required. Both types of

misalignment can occur in horizontal and vertical

planes and are present in most applications.

4.8.2.1 Angular misalignment

In angular misalignment, the centerlines of the shafts

intersect, but are not on the same axis; see Fig.4.

Fig.4 Angular misalignment

4.8.2.2 Offset misalignment

In offset misalignment, the shaft centerlines are

parallel but do not intersect; see Fig.5.

Fig.5 Offset misalignment

4.8.2.3 Combination of angular and offset

misalignment

In combined angular and offset misalignment, the

centerlines of the shafts do not intersect, and are not

parallel; see Fig.6.

Fig.6 Combination of angular

and offset misalignment

4.8.3 Alignment

Ensure pump and driver [8000] are

isolated electrically and the coupling [7000] halves

are disconnected.

4.8.3.1 Measure gap

The first step in shafts / coupling [7000] alignment is

to bring the pump and driver [8000] shafts into their

proper axial position. This is done by pulling the

pump shaft [2100] out towards the driver [8000] until

the balance disc [6210] will not permit further

movement. Then with the aid of a Dial Test Indicator

move the shaft [2100] back 0.25mm (0.010 in.). This

sets the shaft [2100] in its correct positive relative to

float position. The driver [8000] is then moved to

attain the desired spacer gap which is shown on the

General Arrangement Drawing to within 0.25mm

(0.010 in.).

Fig.7 Setting axial gap

In units fitted with shaft position indicator

[2920] note and recorder the shaft [2100] axial

position in shaft position indicator [2920] window, see

Fig.20.

If the driver [8000] is an electric motor

[8000] with sleeve bearings then the magnetic center

at which the rotor will run must be set. This is usually

done by lining up a groove in the shaft to a pointer

fixed to the motor [8000] body

Refer to Driver [8000] Manufactures

instructions.

If the driver [8000] does not run in its

magnetic centre the resultant additional axial force

may overload and damage the pump.

Move driver [8000] to insure proper gap distance.

Loading...

Loading...