FLEX User Instruction – 21TEM14546 EN

Page 12 of 43

3.3 Function in an RO system

The Flowserve FLEX™ is an isobaric energy recovery device designed for reverse osmosis (RO)

seawater desalination applications. It takes the energy of a high-pressure fluid waste stream

and transfers the pressure energy to a low-pressure fluid supply stream. The simple design does

not require any external power, has only one moving part, and uses corrosion-proof materials for

high reliability and long life.

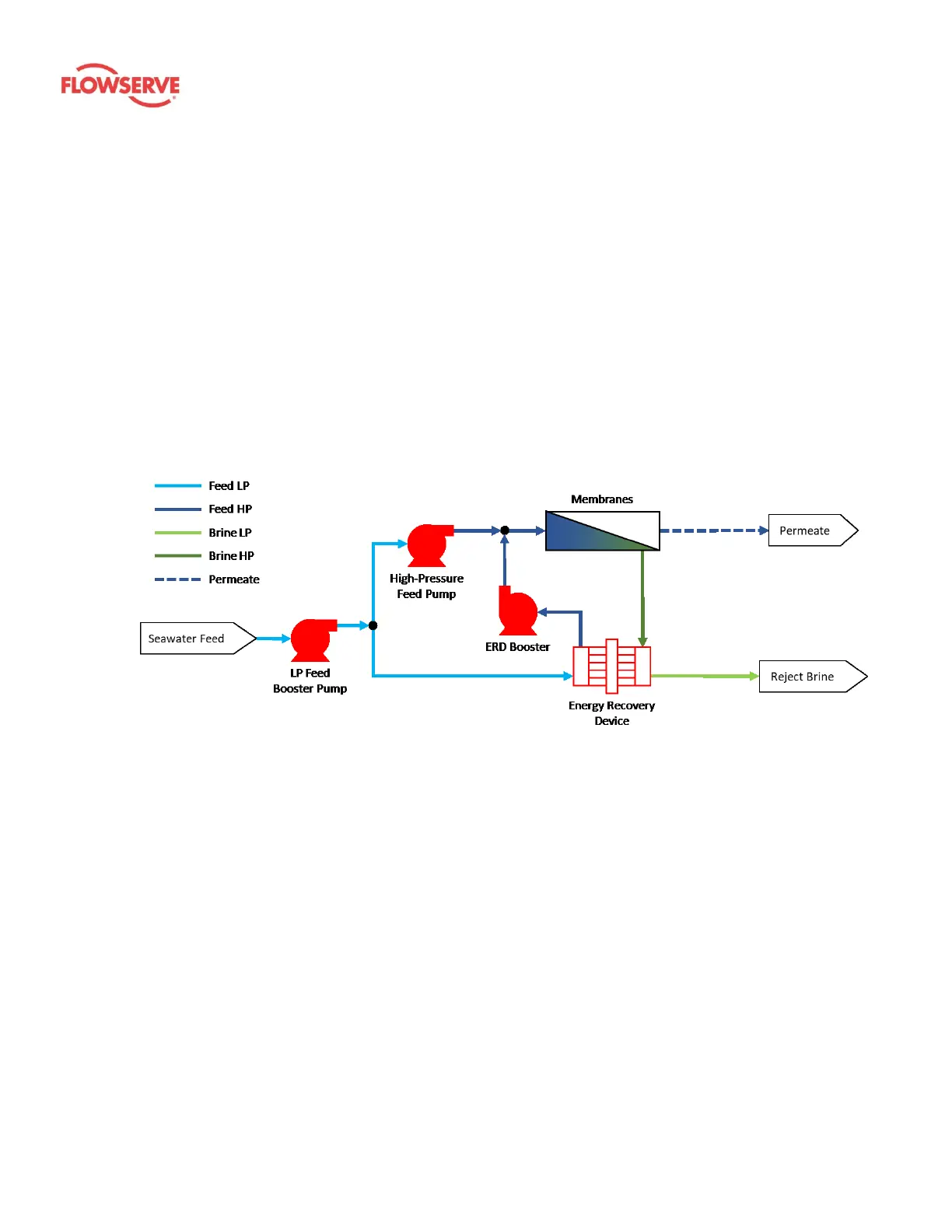

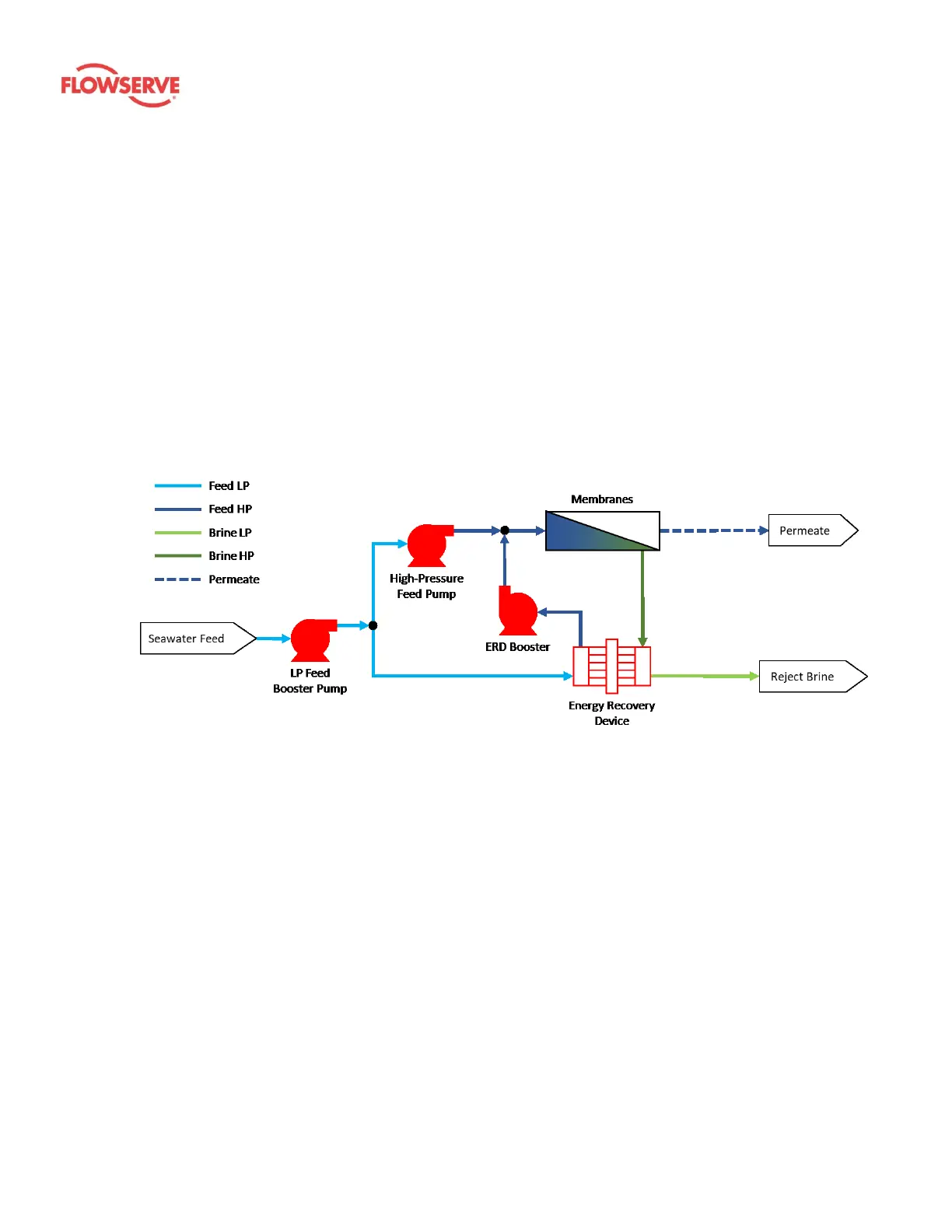

In an RO desalination application like the one shown in Figure 2, the high-pressure waste stream

entering the FLEX is brine leaving the membrane filters. The energy from this brine is transferred

to low-pressure seawater provided to the FLEX from the system’s low-pressure feed pump.

Seawater then leaves the FLEX at nearly the same pressure as the incoming brine. A small

booster pump is used to overcome piping friction losses between the brine outlet of the

membrane and the point that this seawater will be injected back into the membrane inlet. The

final outlet of the FLEX unit is the brine reject leaving at low-pressure. A control valve is used at

this location to maintain a minimum backpressure on the device.

Figure 2: Process flow diagram for a typical FLEX system

There are three sources of energy loss through the FLEX device: hydraulic, volumetric, and

mixing. Hydraulic loss occurs due to friction loss of fluid flowing through the device and

providing energy to drive rotation of the rotor. This is measured as a pressure differential from

inlet to outlet of the device on both the high-pressure and low-pressure sides. Volumetric loss is

caused by fluid leaking from high-pressure to low-pressure inside the device, providing

lubrication and cooling to the bearing surfaces. Mixing loss occurs due to turbulence at the

interface between brine and seawater inside the rotor ducts, and results in a small increase in

salinity of the seawater as it flows through the FLEX from low-pressure inlet to high-pressure outlet.

3.4 System design

A backpressure control valve must be included in the low-pressure brine discharge line. The

valve should be appropriately sized and selected to allow throttling of the flow to maintain

backpressure at or above the minimum level required by the FLEX. Maintaining backpressure at

or above the minimum required level will reduce cavitation and prolong life of FLEX unit(s).

Loading...

Loading...