FLEX User Instruction – 21TEM14546 EN

Page 29 of 43

7.3 Tools, equipment, and fixtures

The device can be completely assembled and disassembled with standard tools and

equipment. All hardware is in nominal English sizes.

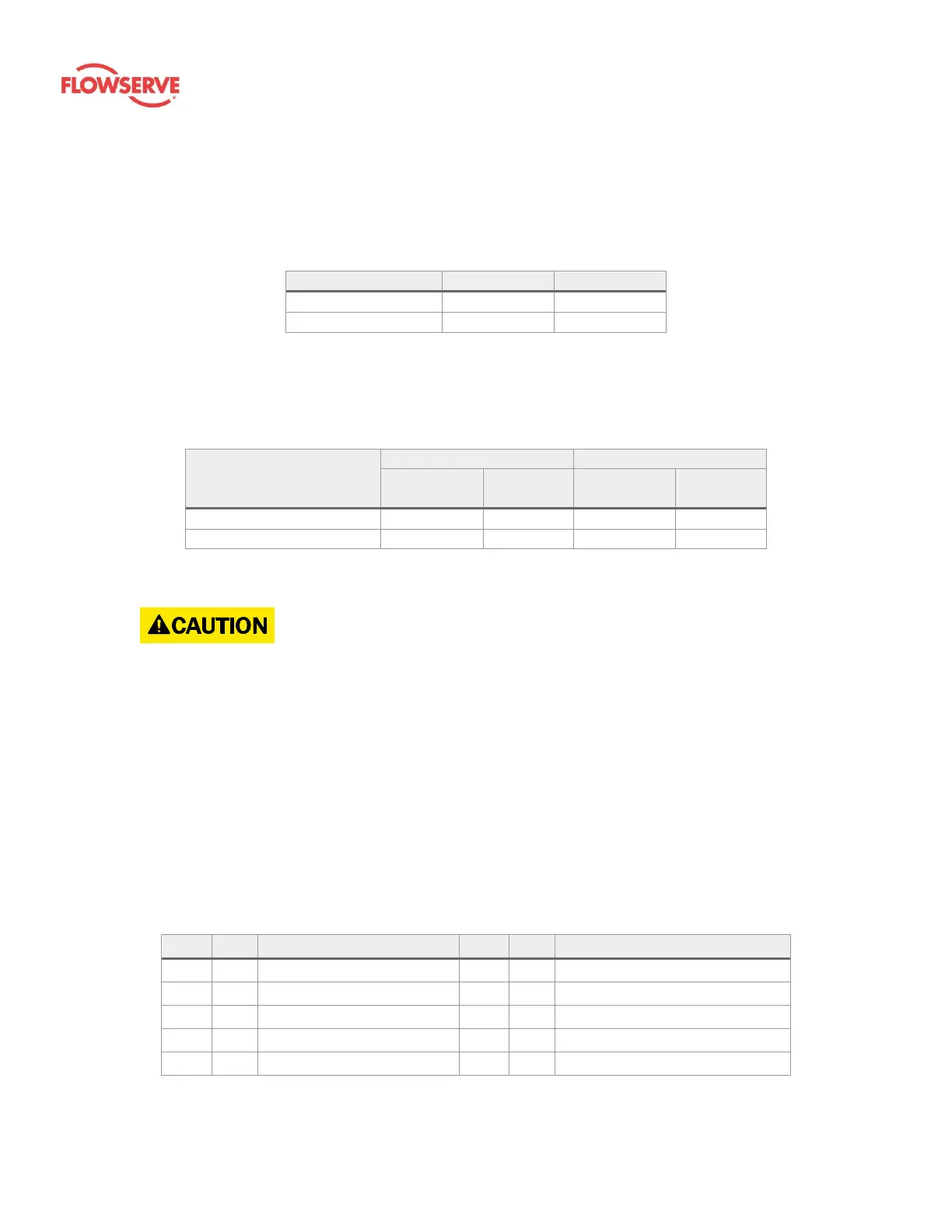

Table 3: Required wrench and socket sizes (inches)

7.5 Disassembly

FLEX MUST BE DULY SUPPORTED TO ENSURE STABILITY DURING ASSEMBLY

1. Remove vessel flange fasteners.

2. Remove one of the vessel halves. Use caution to avoid damaging ceramic cartridge

components with the metal vessels.

3. Discard the vessel flange O-ring.

4. Remove the remaining vessel from the cartridge. Use caution to avoid damaging

ceramic cartridge components with the metal vessels.

5. Remove and discard the balance pocket O-rings and end cover O-rings.

Disassembly of the cartridge without training from Flowserve personnel is not recommended.

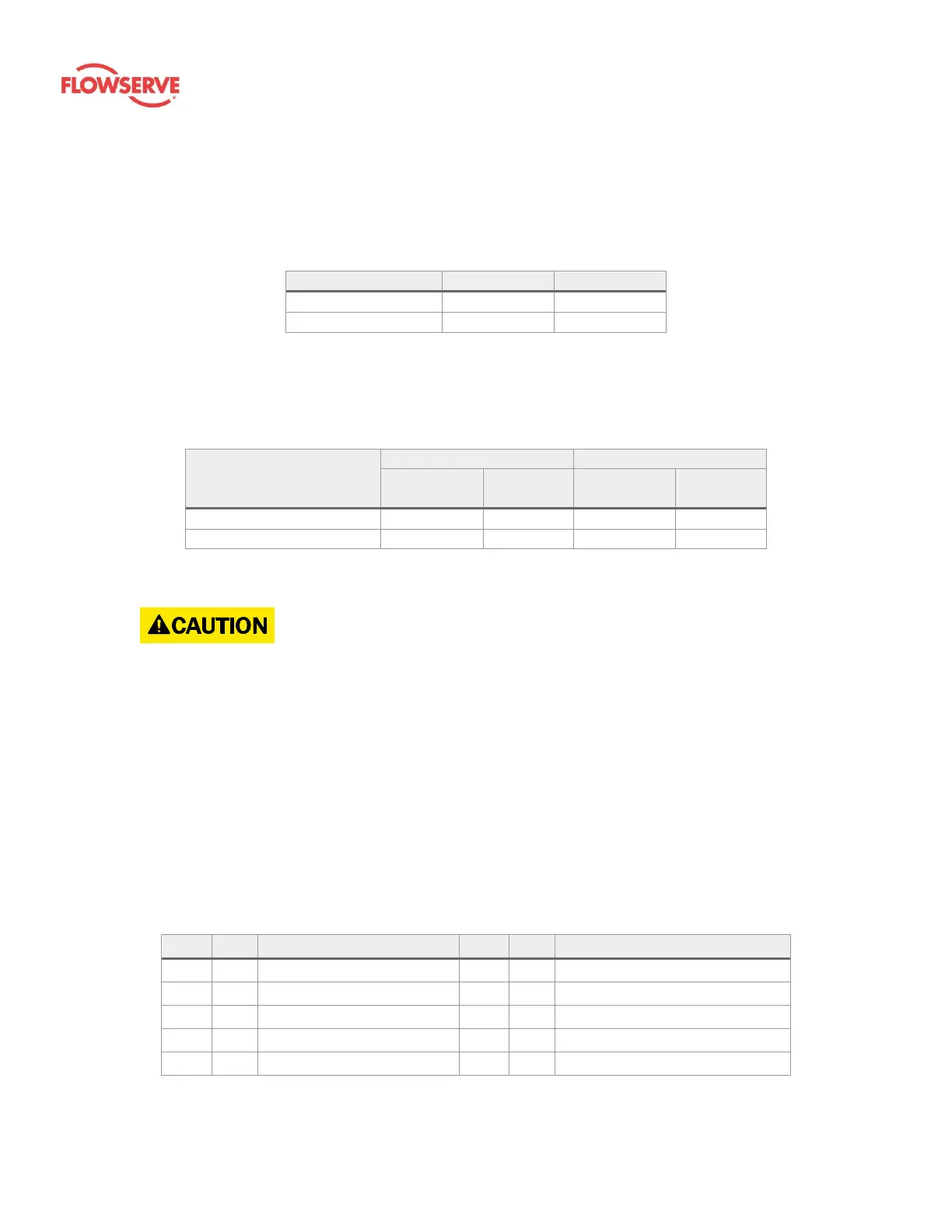

Table 5: Parts list

Loading...

Loading...