FLEX User Instruction – 21TEM14546 EN

Page 13 of 43

Filtration of the process fluid must occur upstream of the FLEX device to avoid damaging the unit

and the precision clearances inside of it. Filters should have a maximum particle size of 20 μm

(0.8 mils) or smaller.

A circulation pump (or booster pump) is required on the high-pressure side of FLEX system piping.

This pump is used to overcome system resistance as process fluid flows from the membrane

outlet, through the FLEX, and back to the high-pressure feedwater inlet of the membranes. This

pump should be installed with either a variable speed drive or a throttling valve to control high

pressure flow rate through the FLEX.

Pressure relief devices should be provided on system piping to prevent over pressurization of

either the FLEX device or low-pressure system piping. Over pressurization may create a hazard

for personnel or result in damage to the FLEX device. It is recommended to install appropriately

sized and rated pressure relief devices on the high-pressure and low-pressure inlets to the FLEX.

Flushing lines should be connected to the system in a way that allow independent flushing of the

high-pressure and low-pressure system piping around the FLEX device.

Vent connections should be placed to ensure that system piping and FLEX units can be

completely flooded, and all air can be purged from the system before startup.

Isolation valves and drain lines should be appropriately placed in system piping to allow isolation

of the FLEX units(s) from the system for safe inspection and maintenance.

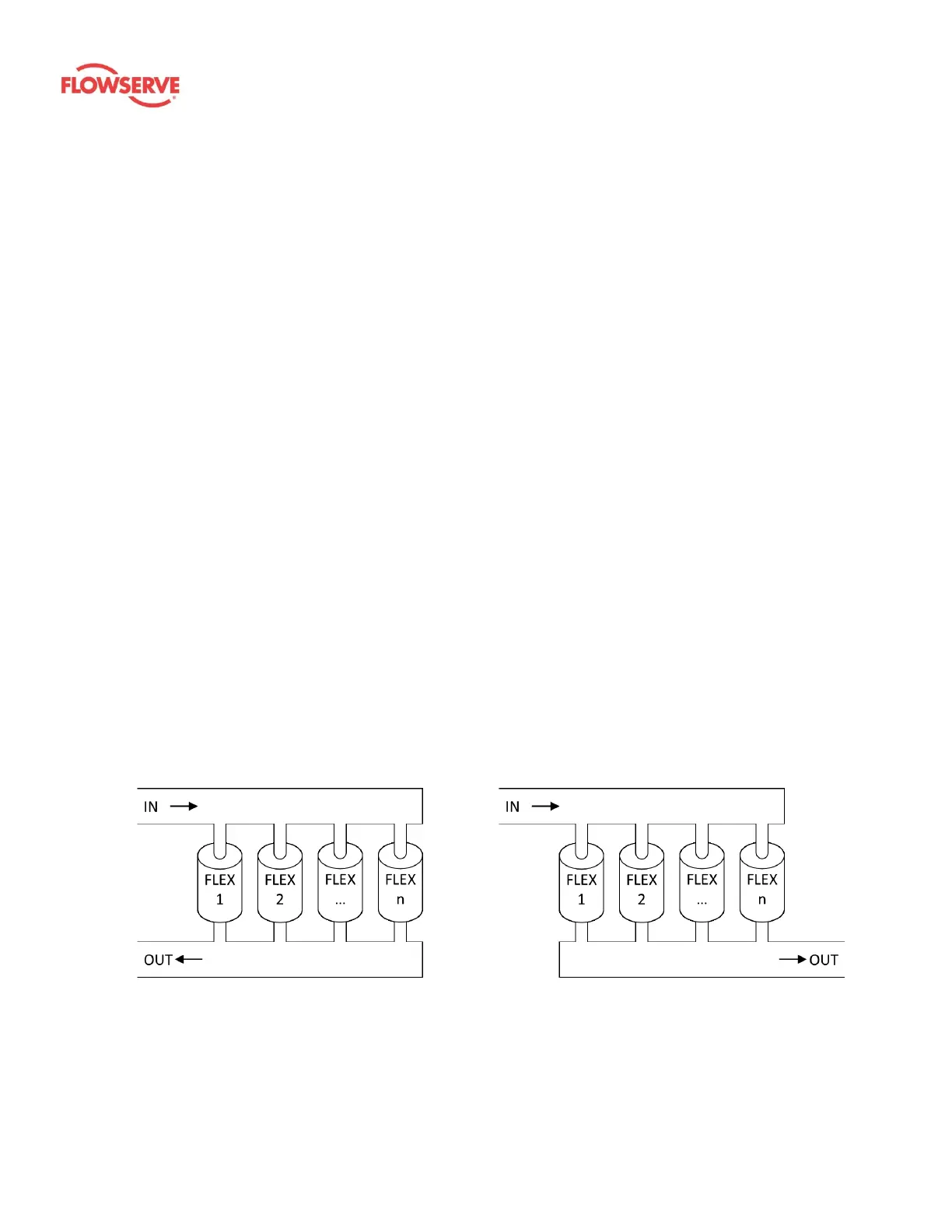

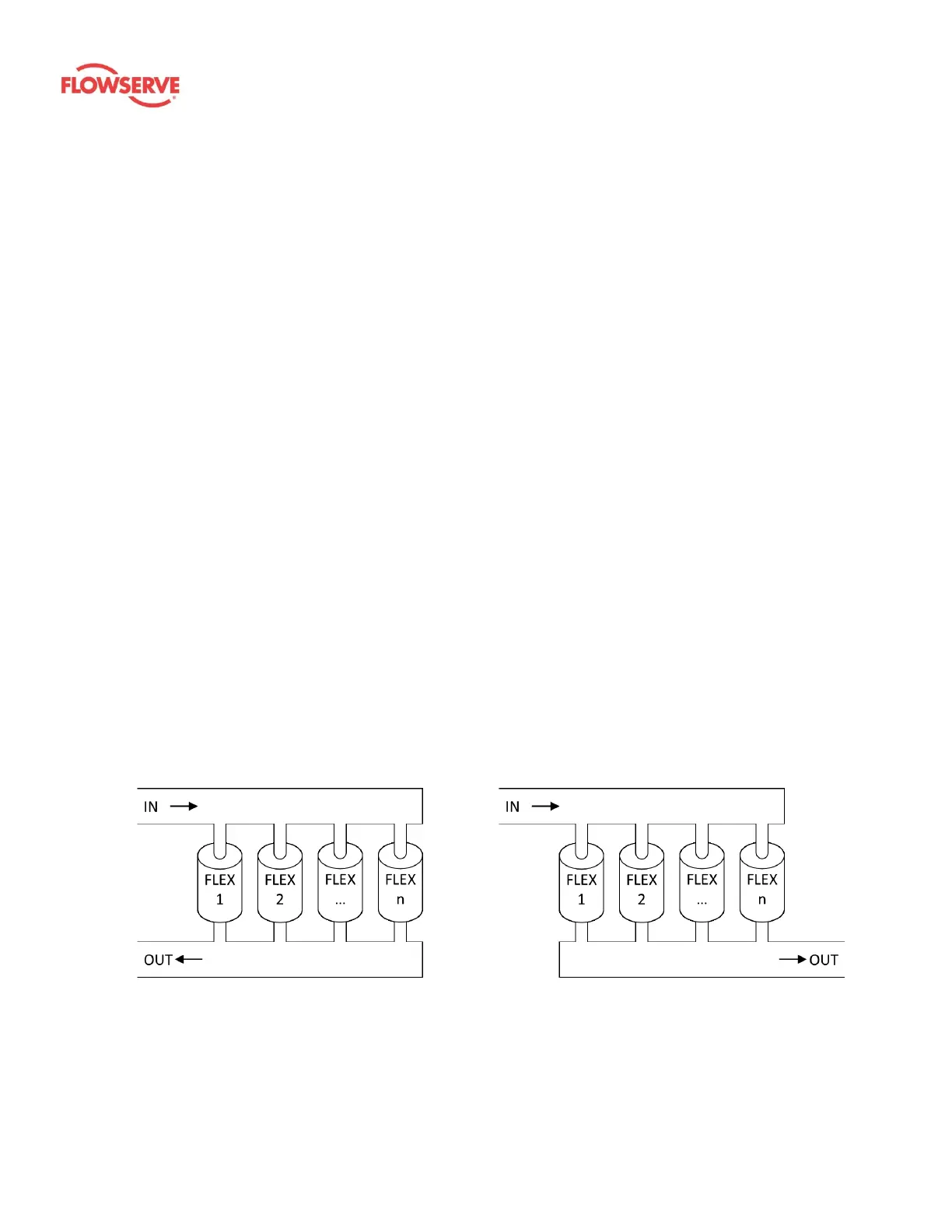

3.5 Header design

Headers can be used to place multiple FLEX units in parallel and achieve higher total system

flow than would be possible with any single unit. Care should be taken in designing the header

system to ensure that an even flow distribution between FLEX units is achieved. An uneven flow

distribution can result in excessive mixing and unreliable operation.

Two flow configurations can be used to design the headers for a rack of FLEX units: U-flow and Z-

flow configurations. U-flow has flow that enters and leaves on the same side of the rack. Z-flow

has flow that enters on one side of the rack and leaves on the other size. Examples of these

configurations are shown in Figure 3 and Figure 4.

Loading...

Loading...