FLEX User Instruction – 21TEM14546 EN

Page 33 of 43

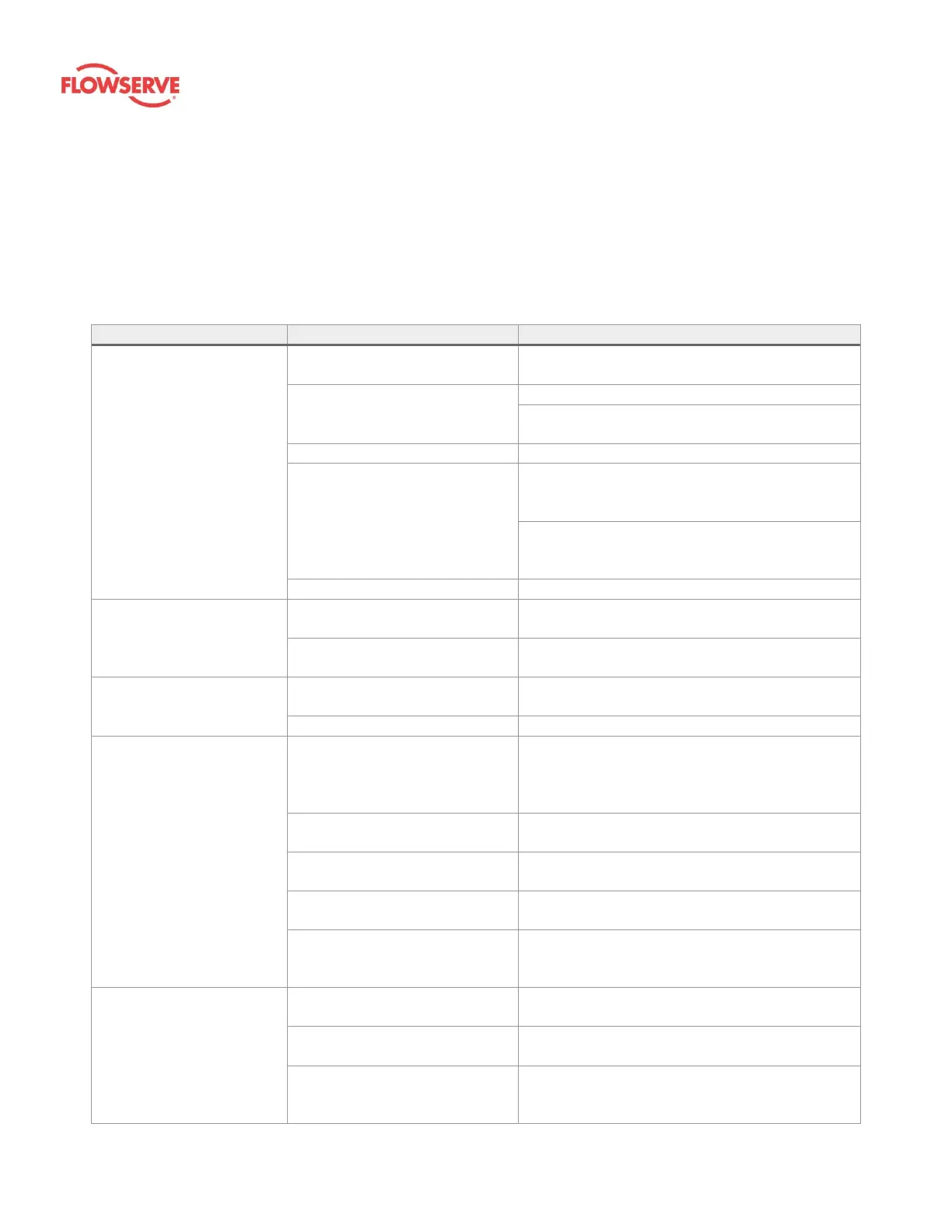

8 Troubleshooting Guide

The following table provides useful guidance on troubleshooting the FLEX energy recovery

device. This guide is meant to cover the most common problems that might occur. If situations

outside this scope are encountered, and experienced operators and maintenance personnel

are unable to remedy the situation, please consult with Flowserve’s field service department.

Table 6: Troubleshooting recommendations

Backpressure below

minimum requirement

Increase feedwater system backpressure

by adjusting valve on brine out flow

Add units in parallel to increase total

system capacity

Unit or cartridge installed

upside down

Verify the unit has been installed in the

correct orientation with port labels

matching system pipe services.

Dismantle unit and check for proper

cartridge orientation: seawater end cover

on the same side as seawater vessel.

Replace cartridge or entire unit

High pressure pump flow is

too high

High salinity in high pressure

feedwater

High salinity in high

pressure feedwater

Check and balance system flow rates.

Increase feedwater flow to reduce mixing.

Stalled rotor

(no measurable or

audible rotation)

Foreign debris, scaling, or

biological growth in device

Flush the device and system with fresh

water. Disassemble, remove debris, and

clean components. Replace cartridge or

unit if damaged by foreign debris.

High pressure is above rated

maximum

Feedwater flow is below

minimum

Insufficient lubrication flow

across bearing surfaces

Increase high pressure to provide

lubrication to rotor bearing surfaces

Cartridge rotated inside

vessel

Disassemble unit, replace O-rings,

reassemble unit with proper cartridge

orientation in vessels.

Excessive leakage flow

(HP feedwater flow

significantly lower than

HP brine flow)

Worn or damaged

clearances

Replace cartridge or unit

Damaged end cover or

balance pocket O-rings

Cartridge rotated inside

vessel

Disassemble unit, replace O-rings,

reassemble unit with proper cartridge

orientation in vessels.

Loading...

Loading...