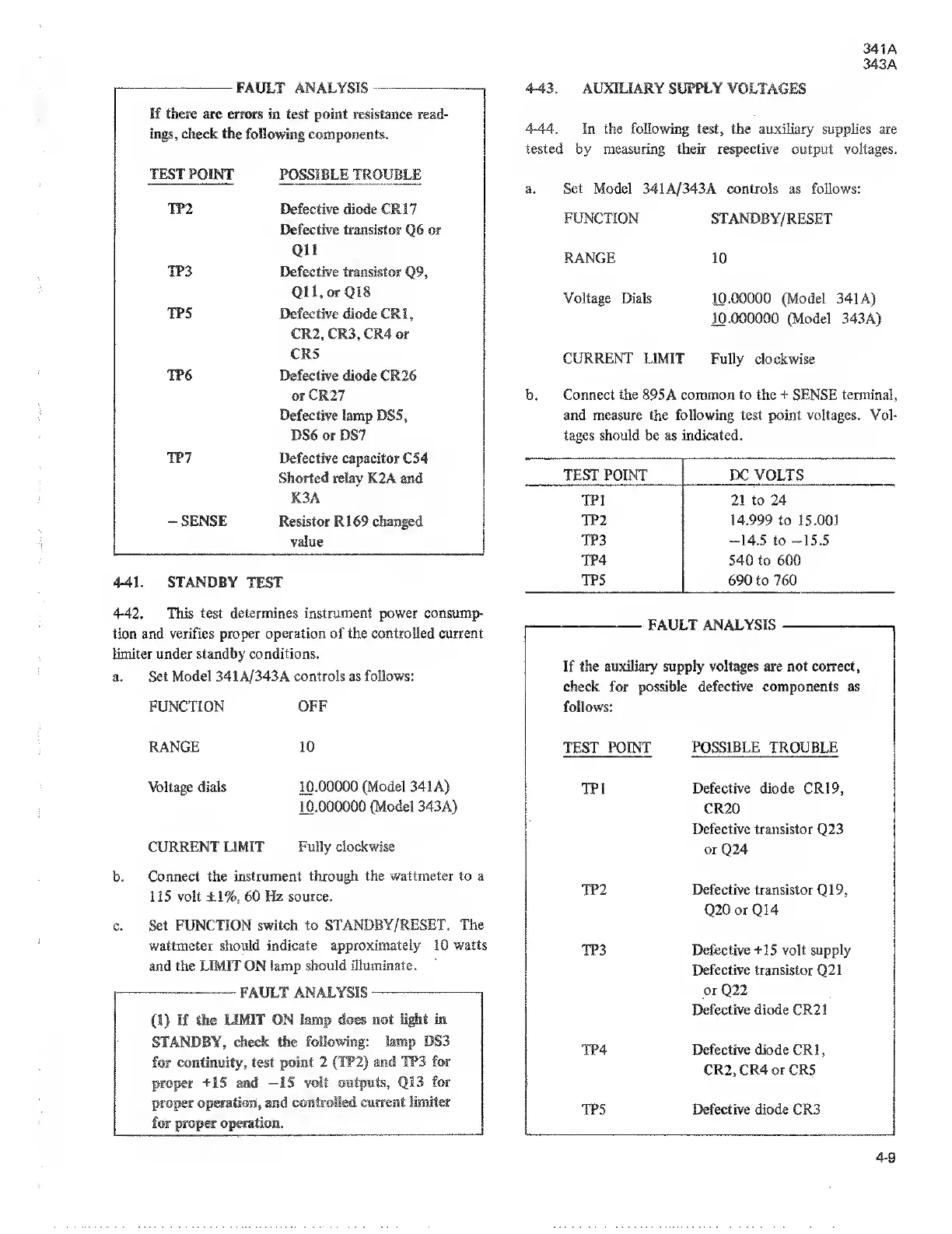

FAULT

ANALYSIS

If there

are errors in test point resistance

read-

ings,

check the following components.

TEST POINT

SENSE

Defective diode CM

7

Defective

transistor

Q6

t

Oil

Defective transistor

Q9,

Q1I, or

Q18

Defective

diode CRi,

CR2, CRB, CR4 or

CR5

Defective diode CR26

or CR27

Defective lamp DS5,

DS6 or

DS7

Defective

capacitor €54

Shorted relay K2A

and

K3A

Resistor R369 changed

value

4-41.

STANDBY

TEST

4-42.

This test

determines instrument

power

consump-

tion and verifies proper operation of the controlled current

Limiter under standby conditions,

a. Set Model 341 A/343A

controls as follows:

FUNCTION

OFF

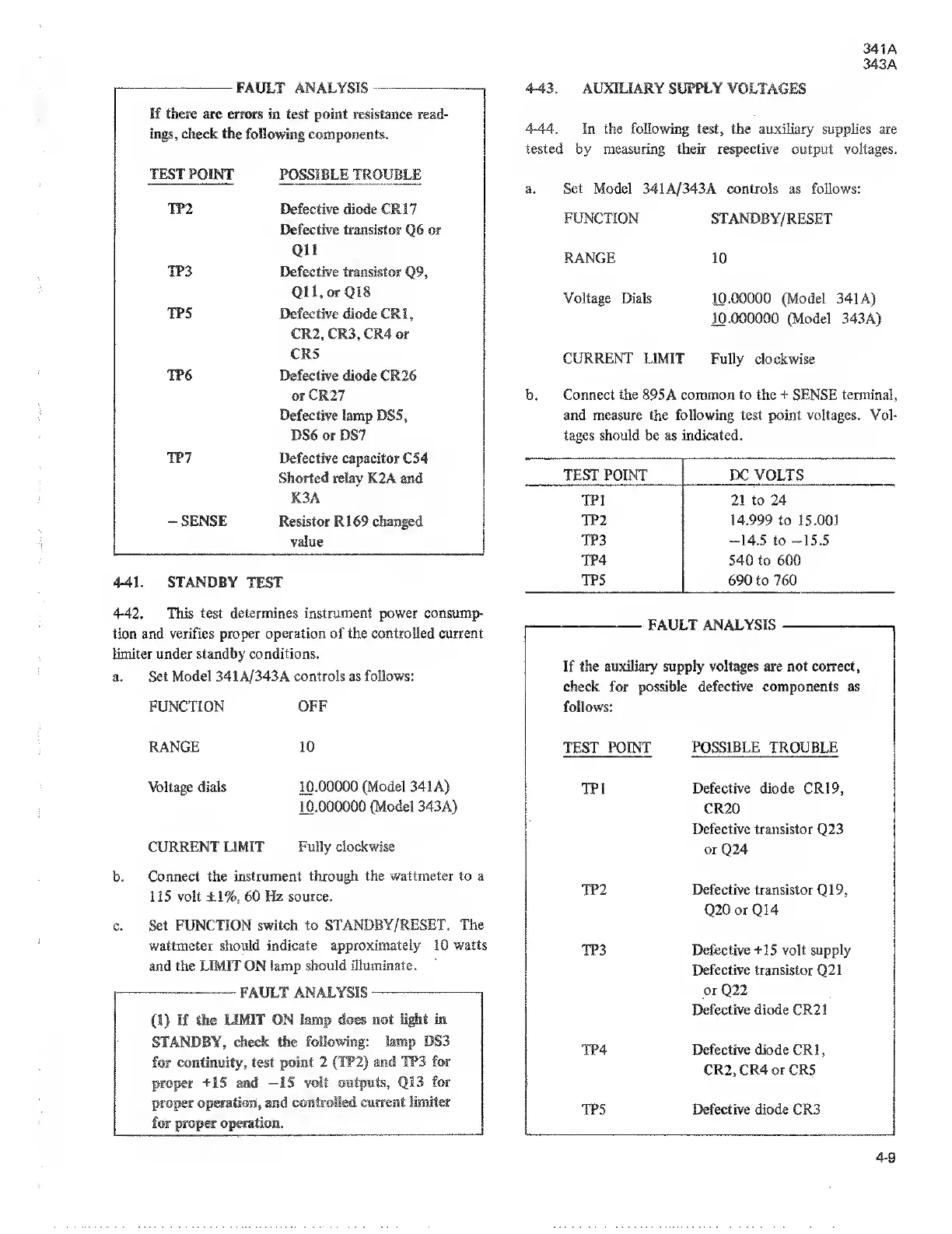

4-43.

AUXILIARY

SUPPLY

VOLTAGES

In the

following

test, the auxiliary supplies are

by

measuring their respective

output voltages.

FUNCTION

RANGE

Voltage Dials

341A/343A

controls

as follows:

STANDBY/RESET

10.00000 (Model 341 A)

10.000000 (Model 343A)

CURRENT LIMIT Fully

clockwise

Connect

the

895A

common to the +

SENSE

terminal,

and measure

the following test

point voltages. Vol-

tages should

be

as

indicated.

TEST POINT PC VOLTS

21

to 24

14.999 to 15.001

-14.5

to

-15.5

540

to 600

690 to

760

FAULT ANALYSIS

If the auxiliary supply

voltages are not correct,

check for possible defective

components as

follows:

RANGE

TEST POINT

POSSIBLE TROUBLE

Voltage dials 10.00000

(Model 341 A)

10.000000

(Model

343A)

CURRENT LIMIT

Fully clockwise

Connect the instrument

through the wattmeter to a

1 15 volt

±1%,

60

Hz

source.

Set FUNCTION

switch to STANDBY/RESET.

The

wattmeter should

indicate approximately 10

watts

and the LIMIT ON lamp

should illuminate,

FAULT

ANALYSIS

,

(1)

If the

LIMIT ON

lamp

STANDBY,

check

the

folic

for continuity, test point 2

proper

+15

and

—IS volt

proper

operation,

and

contro

Defective diode CR19,

CR20

Defective transistor

Q23

or

Q24

Defective transistor

Q19,

Q20

or

Q14

Defective +15 volt supply

Defective transistor

Q21

or

Q22

Defective diode CR2

1

Defective diode

CRI

,

CR2,

CR4

or CR5

Defective diode CR3

Loading...

Loading...