AC Leakage Current Clamp Meter

Performance Tests

5

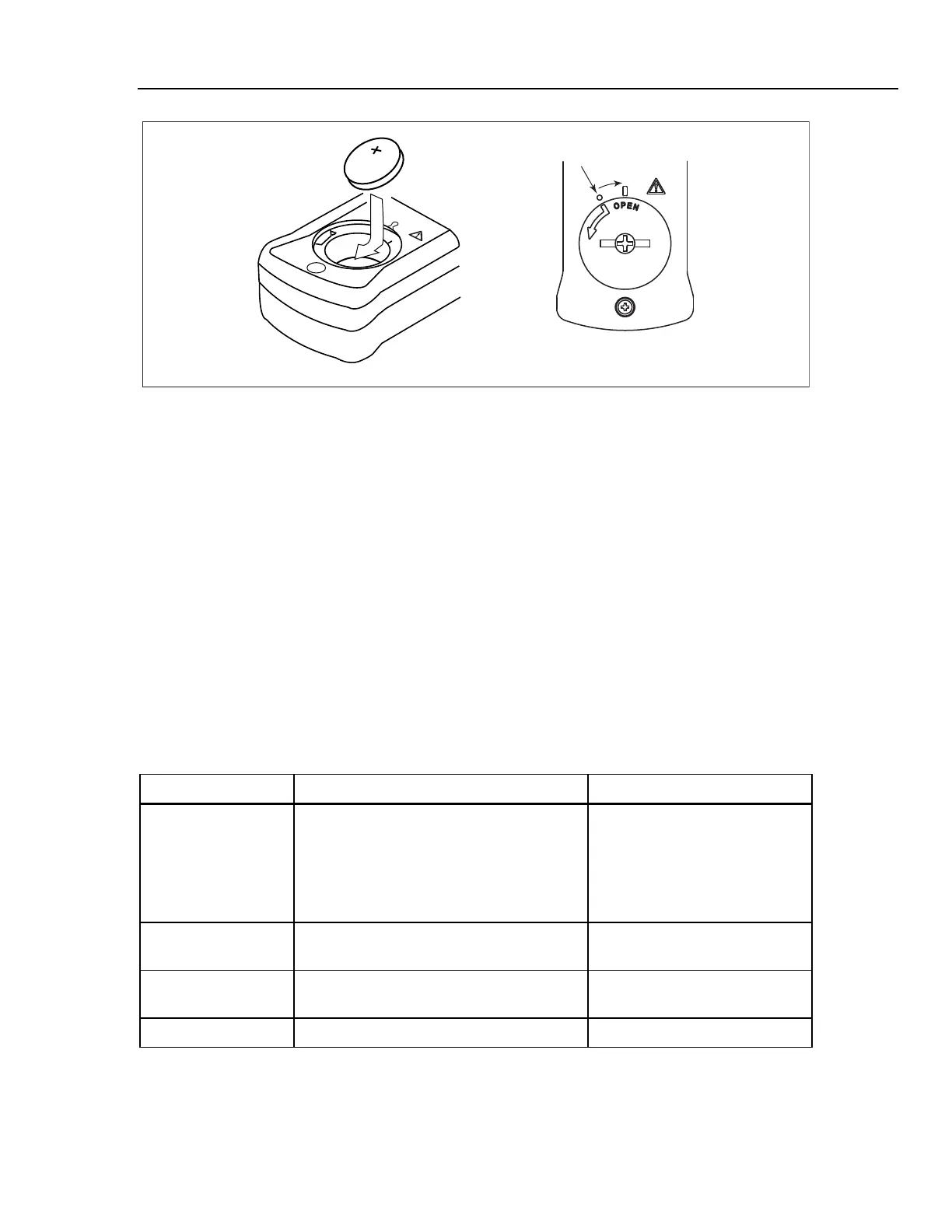

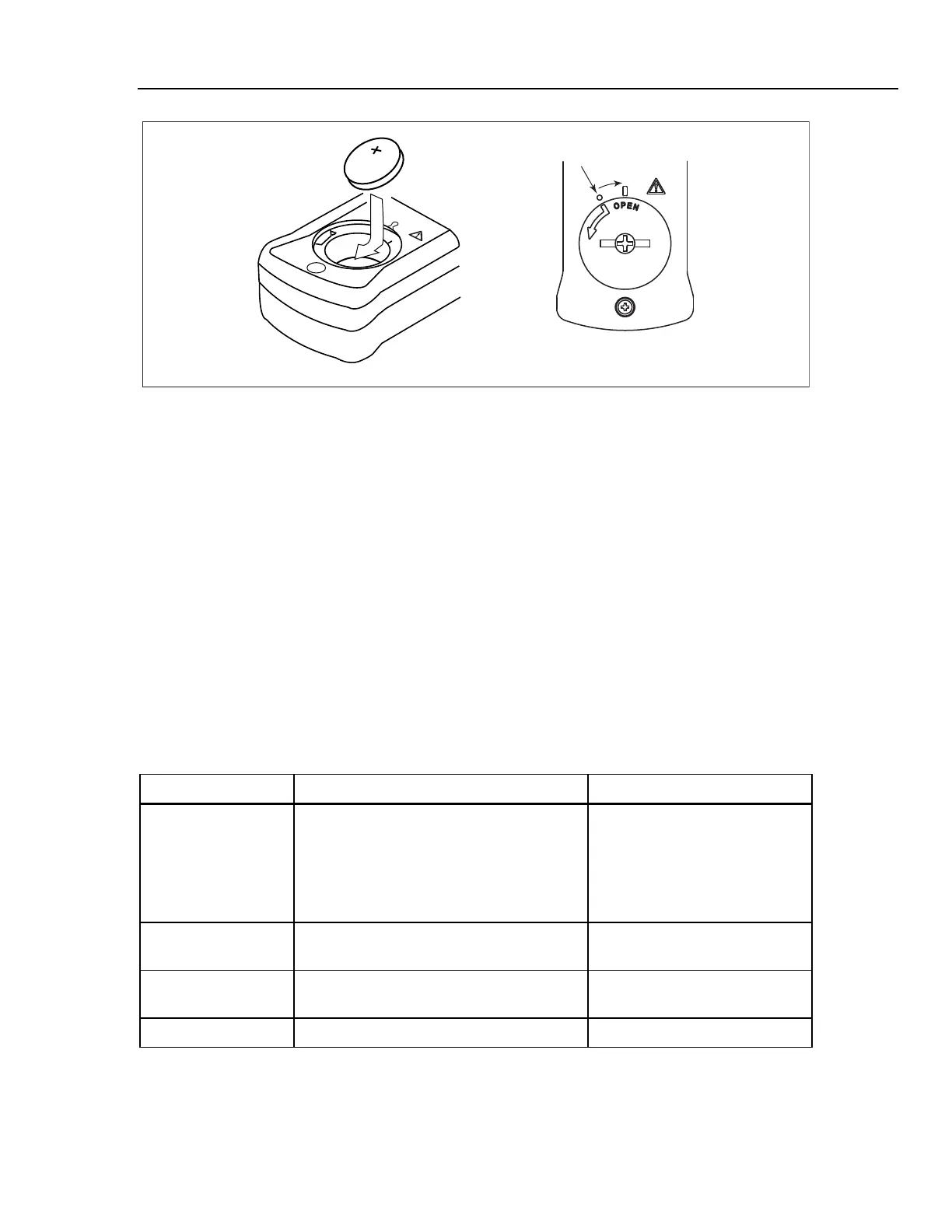

epq003.eps

Figure 1. Changing the Battery

Performance Tests

XWWarning

To avoid possible electric shock, do not perform the

performance test procedures unless the Meter is fully

assembled and you are qualified to do so.

The following performance tests verify the complete operation of the Meter and check the

accuracy of each Meter function against its specifications. The recommended calibration interval

is 12 months. In the performance tests, the Meter is referred to as the unit under test (UUT).

Before you perform any of the following tests, check the battery and replace if necessary. For

more information, see Battery Replacement. If the UUT fails any performance test, contact Fluke

Service for repair. See Contacting Fluke.

Required Equipment

Table 2 lists the equipment required to complete the performance tests.

Table 2. Required Equipment

Equipment Minimum Required Characteristics Recommended Model

Calibrator

AC current:

• Accuracy

ACmA: ± 0.25 %

Amps: 30 A = ± 0.19%

60 A = ± 0.49%

• Frequency = 50/60 Hz

Fluke 5520A High Performance

Multi-Product Calibrator

Magnet wire coil

3 turns, 14-gauge film-coated copper wire,

6-in. diameter

---

Magnet wire coil

2 turns, 14-gauge film-coated copper wire,

6-in. diameter

---

Copper wire coil 1 turn, 14-gauge copper wire, 6-in. diameter ---

Loading...

Loading...