Calibrating a P/I Transmitter

9

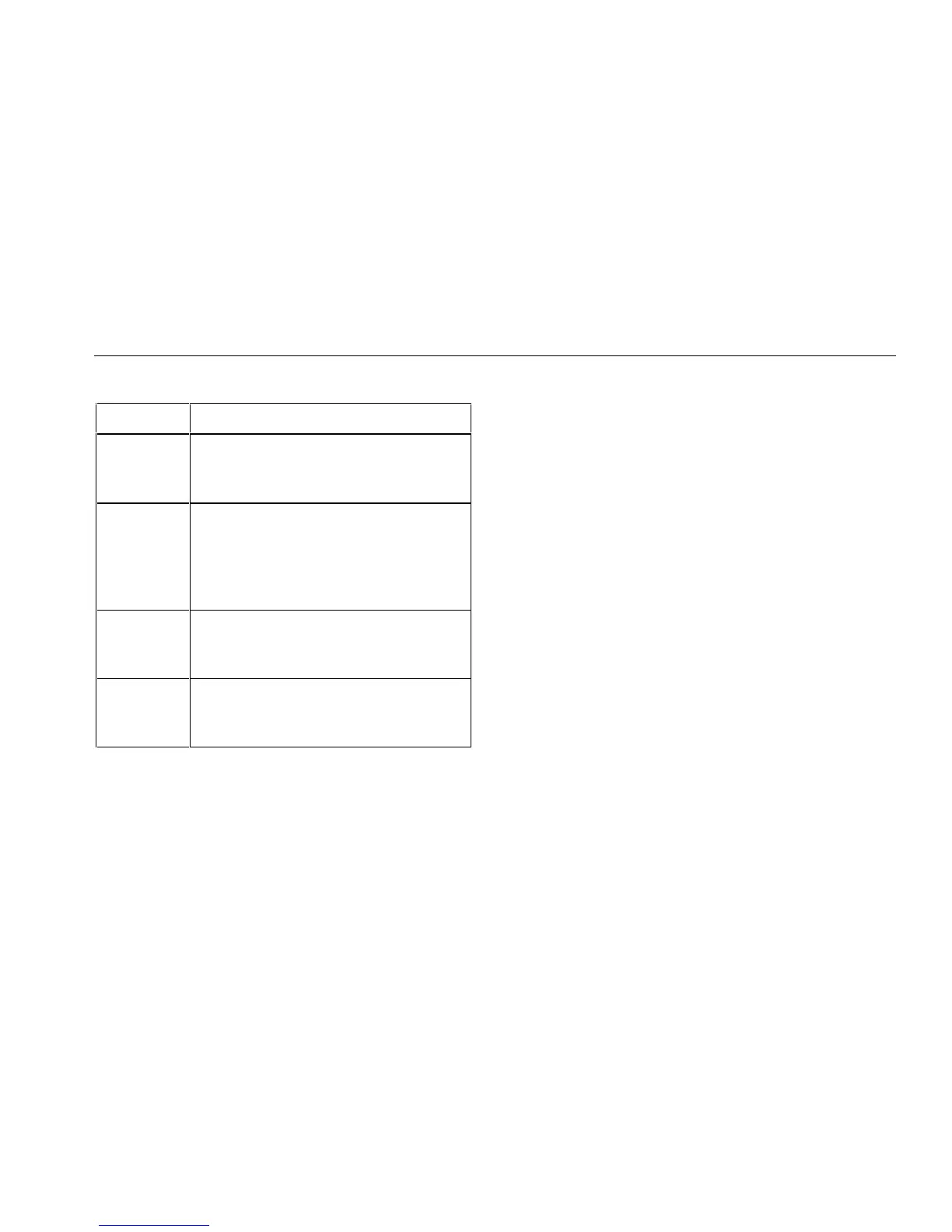

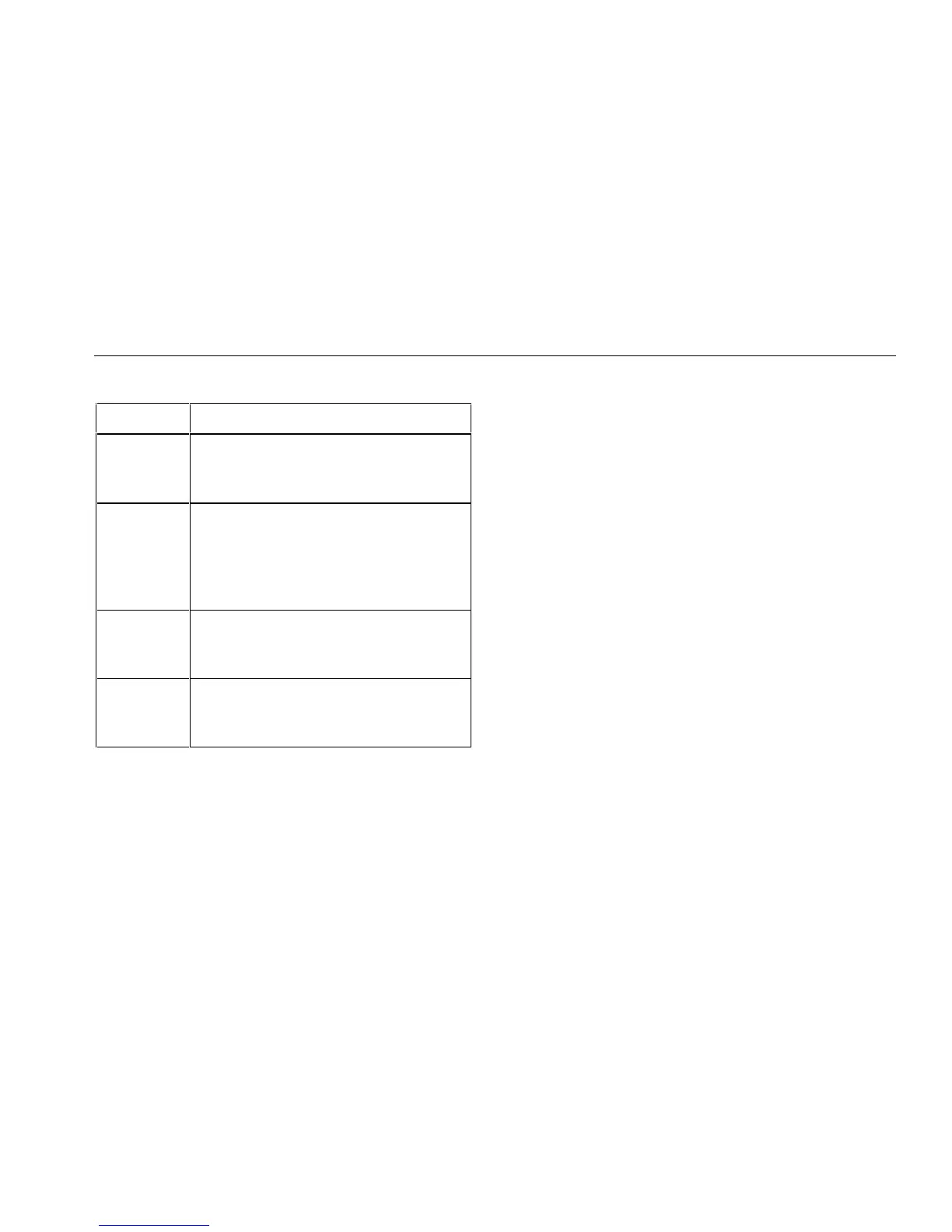

Table 5. Pump Features

Item Description

Pressure

Vacuum

Switch

Rotate forward (clockwise) for pressure,

backward (counter-clockwise) for

vacuum.

Pressure

Vacuum

Release

Valve

Rotate fully backward (counter-

clockwise) to release all pressure or

vacuum. (Rotate slightly for partial

release.) Rotate fully forward (clockwise)

to close valve.

Fine

Adjustment

Knob

Rotate either direction for precise

adjustment of applied pressure or

vacuum. Full rotation is about 30 turns.

Internal

Pump

Increase pressure on the inward stroke.

In vacuum mode, decrease pressure on

the outward stroke.

Calibrating a P/I Transmitter

To calibrate a P/I (pressure to current) transmitter, apply a

pressure to the transmitter and measure the transmitter’s

current loop output. You can apply pressure with the

Calibrator’s internal pump or with an external pump. An

internal relief valve activates when pressure/vacuum

exceeds the rating for the Calibrator model (50-60 psi for

718 30G, 140-150 psi for 718 100G.)

W Warning

To avoid a violent release of pressure or vacuum,

always depressurize the system slowly using the

pressure/vacuum release control before detaching

any pressure line.

Using the Internal Pump

The internal pump can provide 30 psi (2.0685 bar) for

Model 718 30G or 100 psi (6.895 bar) for Model 718

100G.

The preferred use for the internal pump is shown in Figure

4, where the calibrator displays pressure measured with

the internal sensor and provided by the internal pump.

The internal pump can also be used with certain Fluke

700 Series Pressure Modules. In this case, pressure

measured by the Pressure Module is displayed by the

Calibrator. Appropriate Pressure Modules for each

Loading...

Loading...