7341

Users Guide

5-4

F

r

o

n

t

Caster Slots

8

.

5

"

(

2

1

.

6

c

m

)

Wall

haz002.eps

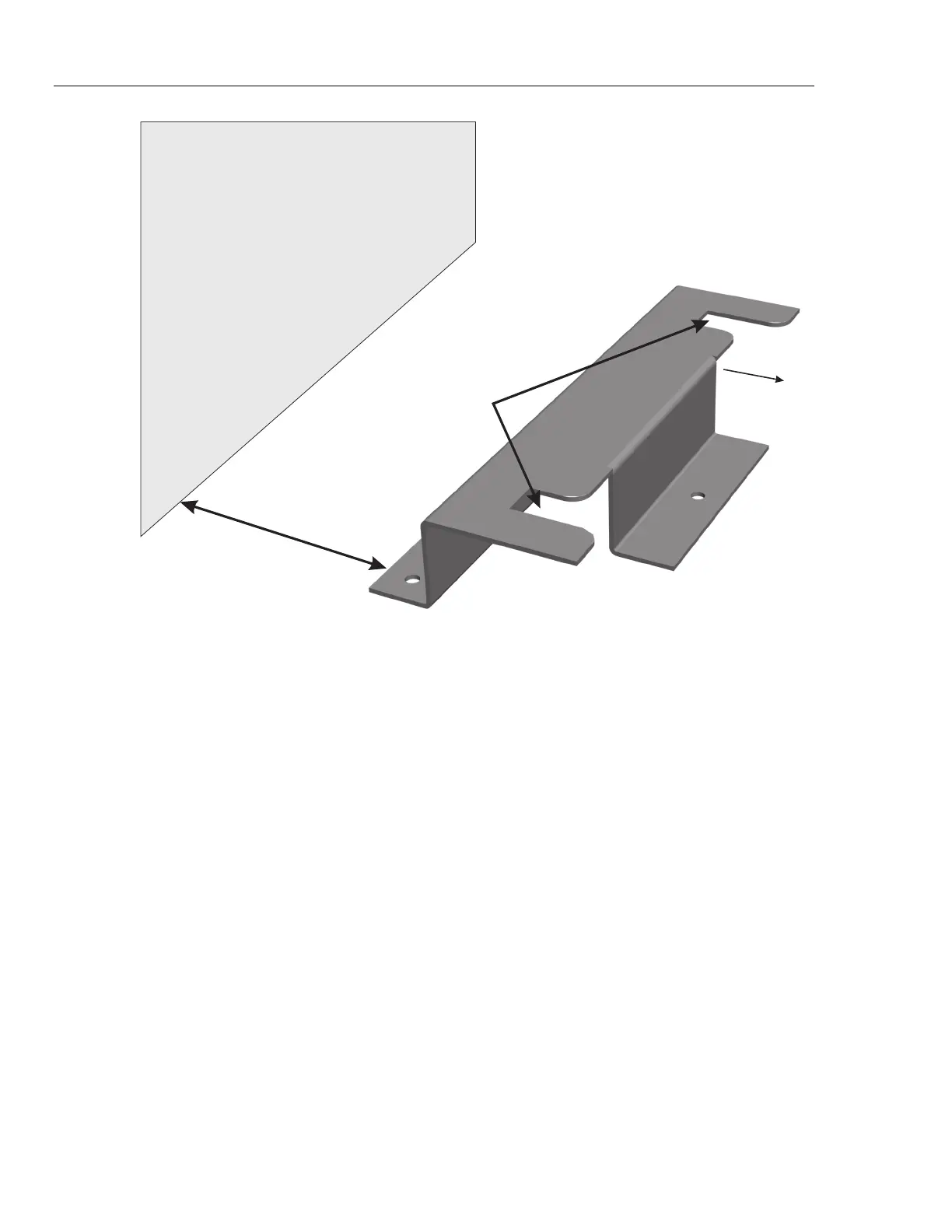

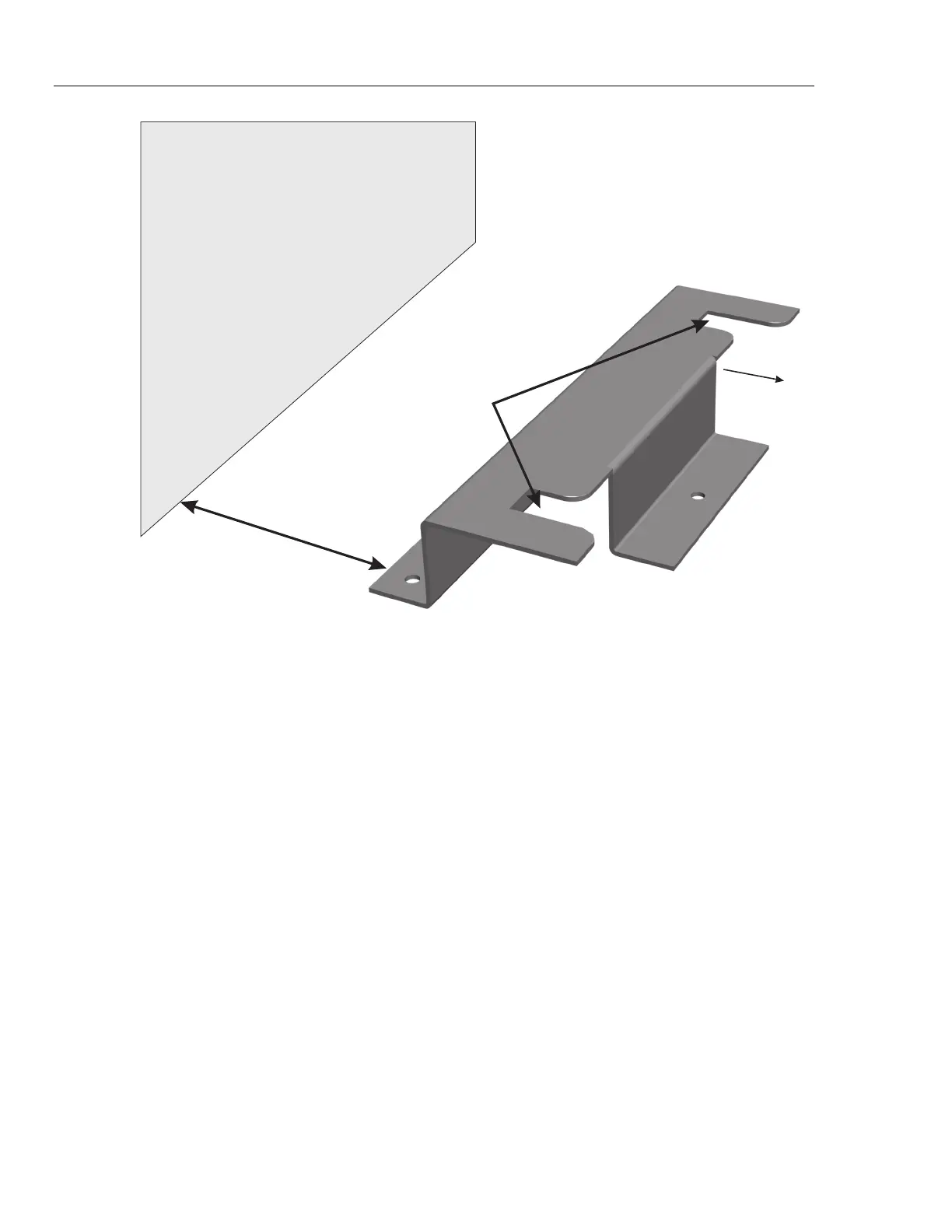

Figure 5-1. Tipping Prevention Bracket Installation

Installation On a Concrete Floor

Using a concrete drill and concrete drill bit, drill three ¼ inch x 1 ¼ inch deep

(approximately 6.5 mm x 32 mm) holes in the concrete floor using the bracket to mark

the hole placement. Drop the flare anchor bolt into the hole. Tightening the screw

expands the anchor in the drilled hole and secures the tipping bracket. Ensure that the

bracket is installed in such a way that the bath will have a minimum of 6 inches of

clearance for air circulation. (See Figure 5-1). Screw the bracket securely to the floor.

Installation Of The Bath

Slide the back casters of the bath completely into the tipping bracket. Lock the front

casters of the bath. Check that the bath is securely locked into the tipping bracket by

gently pushing on the bath. Proceed to fill the bath with the applicable bath fluid after

reading the entire Users Guide.

If you have any questions concerning installation of the tipping prevention bracket,

please contact a Fluke Authorized Service Center.

“

Dry-out” Period

If this equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Before initial use, or after transport, or after storage in humid or semi-humid

environments, or anytime the bath has not been energized for more than 10 days, the

instrument needs to be energized for a "dry-out" period of 2 hours before it can be

assumed to meet all of the safety requirements of the IEC 1010-1. If the product is wet or

has been in a wet environment, take necessary measures to remove moisture prior to

Loading...

Loading...