Page 14 • MN01029 Issue/Rev. 0.5 (6/11)

Section 2 – Clearance Checks (continued)

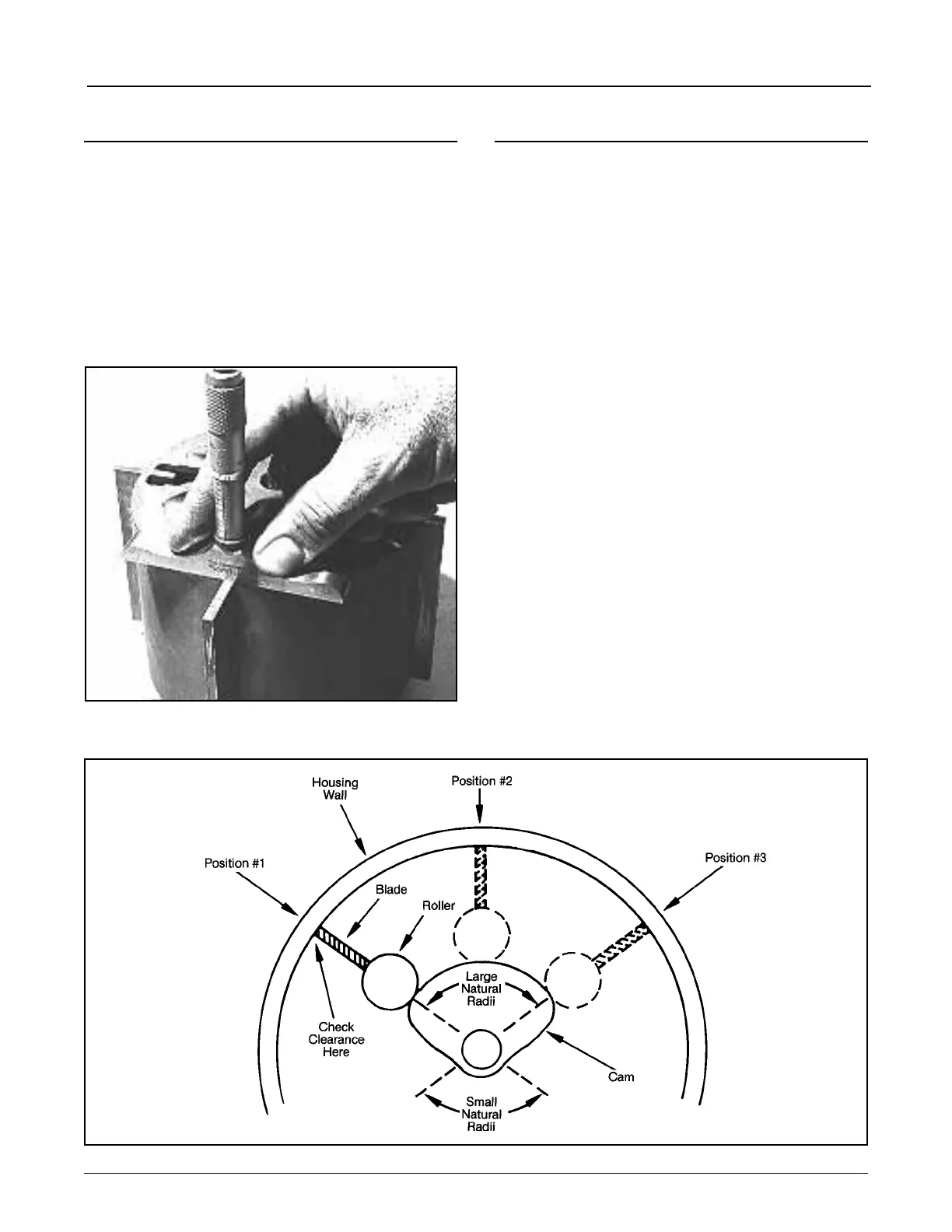

Blade End to Rotor

This check can be made with the rotor assembly in the

meter housing or situated on a flat, even surface.

1. Place depth micrometer on the rotor over the blade

end as shown in Figure 51 and check findings against

Clearance Guide on Page 12.

•Ifadepthmicrometerisnotavailable,afeelergauge

with a straight-edged block of metal may be used.

2. If blade extends over rotor, drop top end to meet

clearance requirement.

3. If blade exceeds clearance requirement, replace.

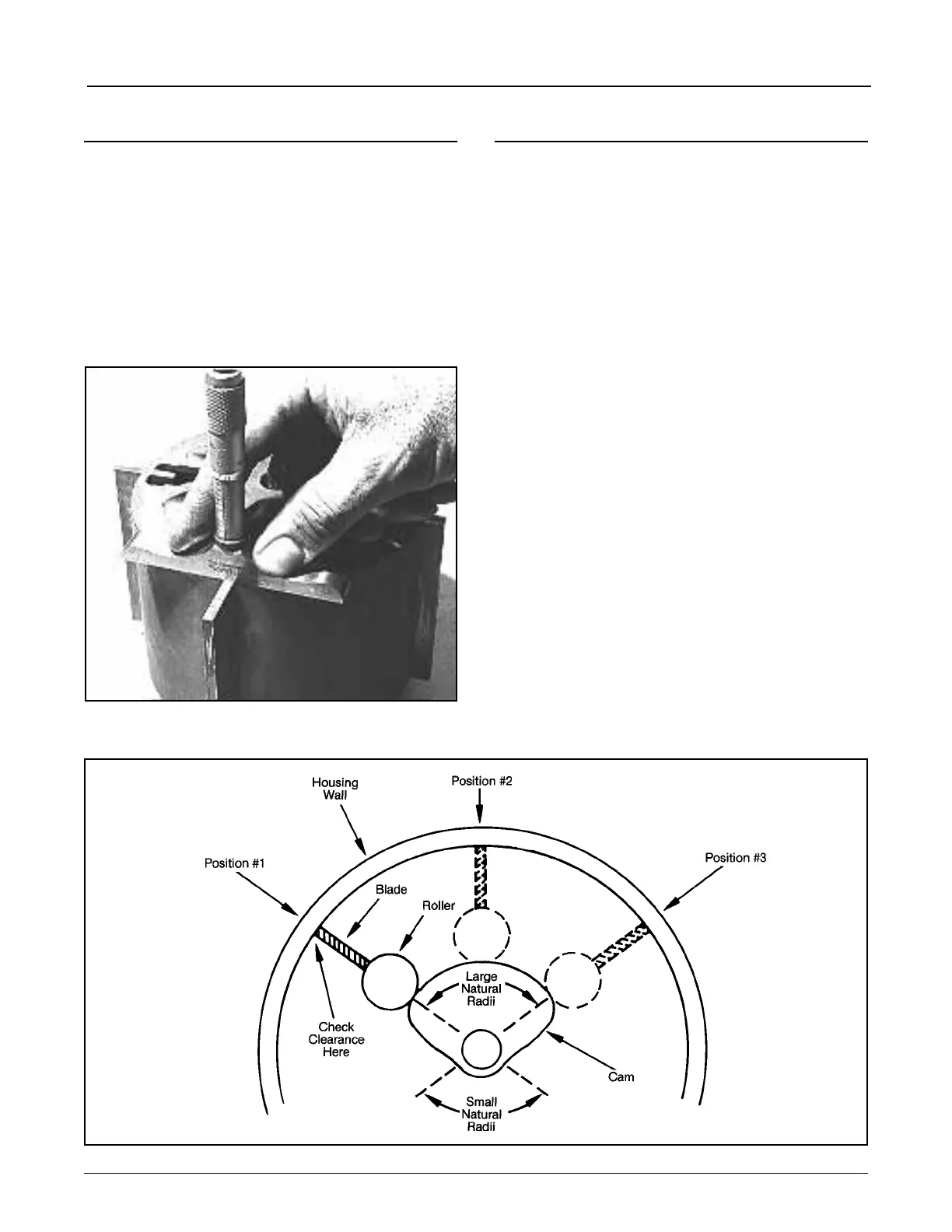

Blade Roller Over Radius Portion of Cam

1. Rotate rotor until a blade is in Position No. 1 as shown

in Figure 52.

2. Forcing blade against housing wall, check clearance

between blade tip and housing wall from top to bot-

tom. Note clearance.

3. Forcing blade away from wall, again check clearance.

• The difference between these two clearance

readings is the blade roller over radius portion

of cam clearance in this position. Check against

Clearance Guide Table 2, Page 12.

4. Rotate rotor assembly until this same blade is in the

middle of the measuring chamber (Position No. 2),

Figure 45.

5. Repeat Steps 2 and 3 and check findings against

Clearance Guide Table 2, Page 12.

6. Again rotate rotor until blade is in Position No. 3,

Figure 45, and repeat Steps 2 and 3. Check clear-

ances against Clearance Guide, Table 2, Page 12.

7. Repeat Steps 1 through 6 with other blade assembly.

8. Record findings, if satisfactory, in Meter Clearance

Record, Page 19.

9. If clearances on any portion of radius of cam do not

fall within recommended limits as shown in Clearance

GuideTable2,Page12,thencheckthefollowing:

• If tolerances are in excess of recommended

clearances, determine if cam or blade roller is worn

(normally, the cam will have the most wear). Replace

worn parts and recheck clearances.

•Therollerinanintegralpartofthebladeassembly

in T-11 and I-75 Meters. In this case, the entire blade

assembly would have to be replaced.

Figure 51

Figure 52

Loading...

Loading...