Issue/Rev. 0.5 (6/11)

MN01029 • Page 9

Section 1 – General Information and Description (continued)

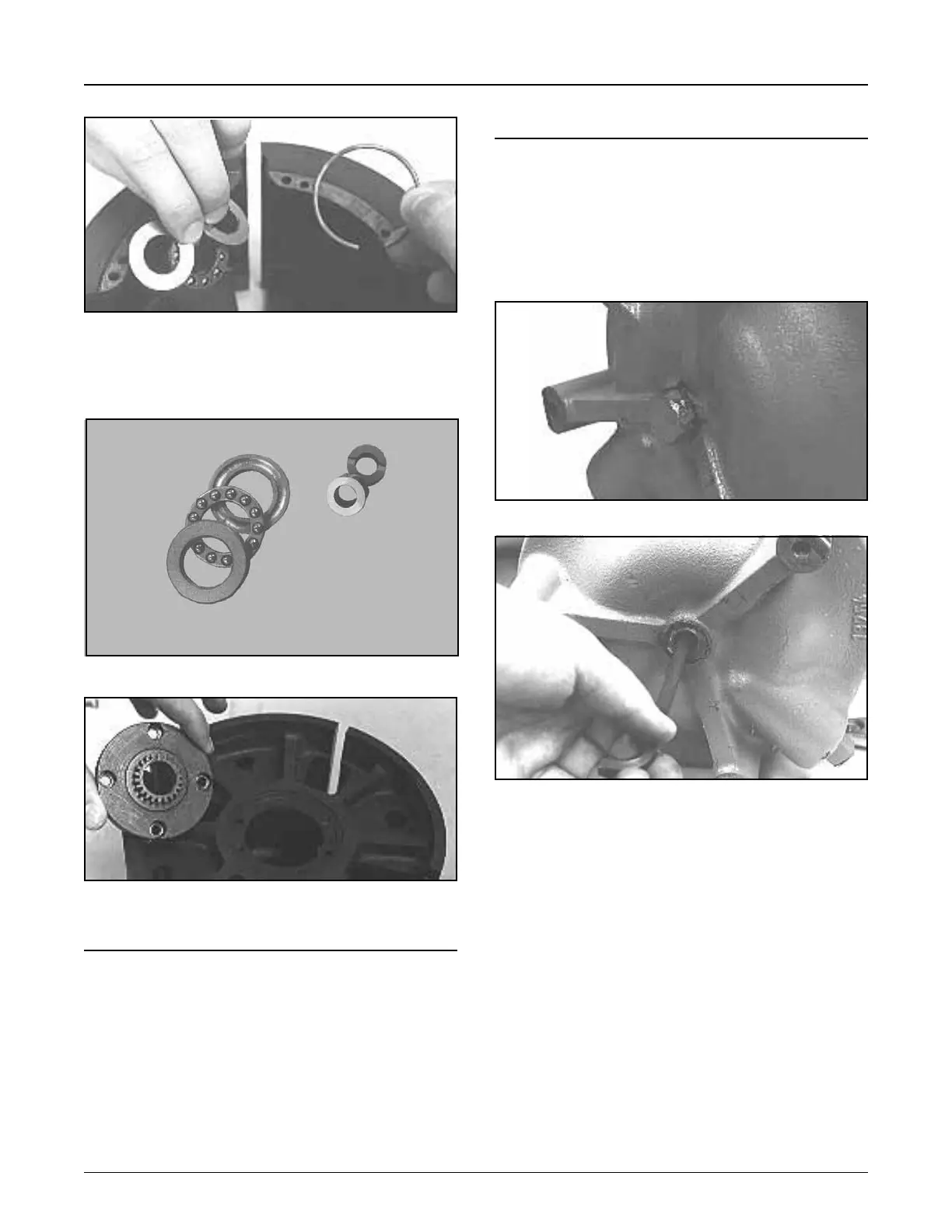

Figure 30

11. Remove thrust bearing and snap ring, Figure 30.

•Seealternatebearings,Figure31.

12. Turn the rotor over and remove gear plate, Figure 32.

Adjusting Rotor End Clearances

Caution: Before any adjustments can be made, the

meter must be removed from the line or drained.

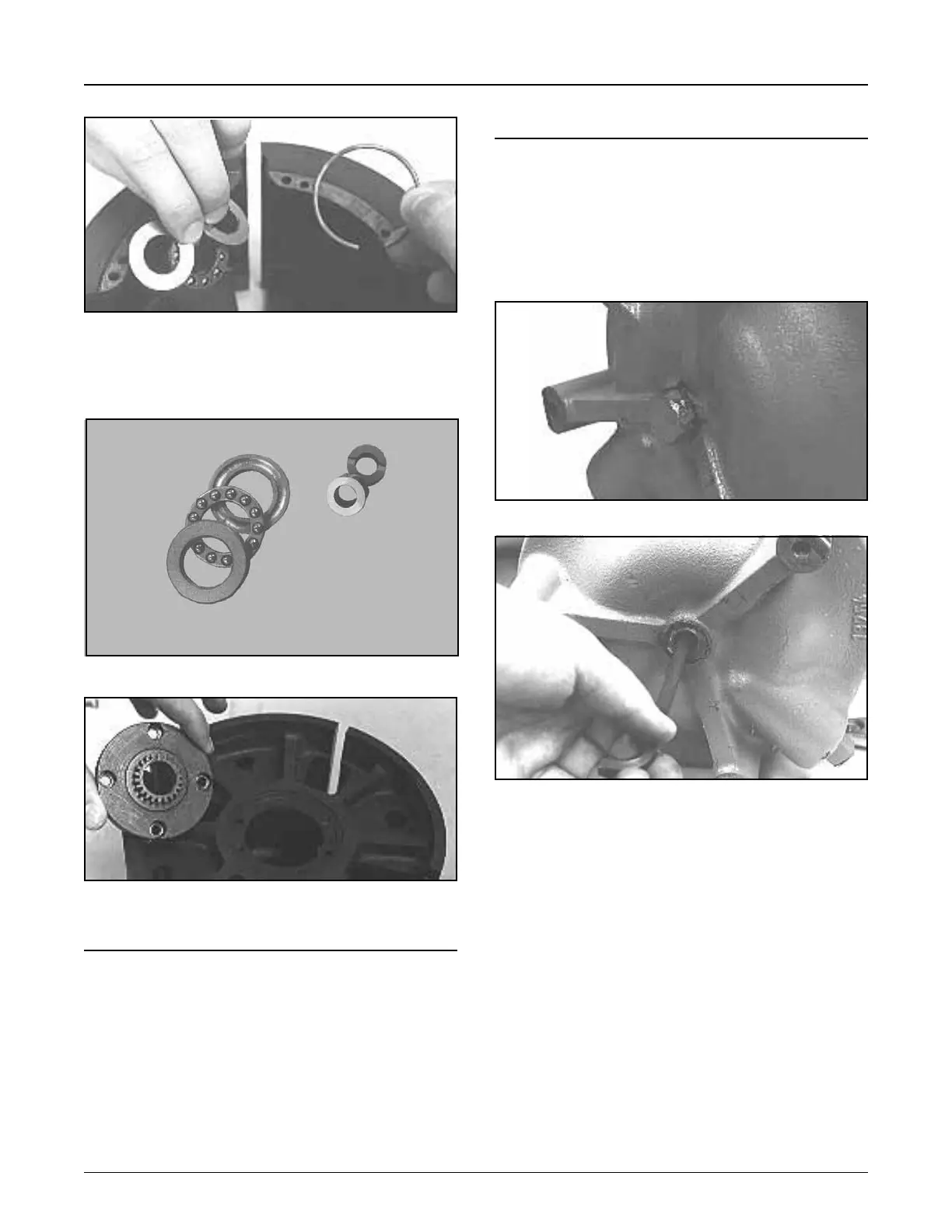

T-11 or I-75 Meters Only

The T-11 or I-75 Meter can have the rotor and adjust-

ments made without removing the calibrator on top of

the meter. An access hole is available on the bottom of

the meter for this adjustment, Figure 33.

Figure 33

Reassembly of Meters

Reassembly is essentially the reverse of the disas-

sembly procedure. Be sure to observe the reassembly

precautions noted duringteardownofunit.

To assist in the reassembly of the meter, refer to the

appropriate parts lists (see Related Publications).

Upon reassembling the meter, clearance checks are

mandatory. Refer to Section 2 — Clearance Checks,

Page 12.

Figure 32

Figure 31

Tungsten Carbide

Thrust Bearing

(SC13 Meter)

Standard

Thrust Bearing

For purposes of illustration, the meter has been placed

on its side for this series of pictures. However, when

actually performing this adjustment, the meter must be

in a vertical position.

1.Withaccessplugremoved,rotaterotorthrougheither

housing port and turn adjusting screw (using a 1/4"

Allen wrench) counterclockwise until resistance is

felt in the rotor rotation, Figure 34.

•Ifrotorisalreadyhardtoturn,thenturnadjusting

screw clockwise until rotor just begins to rotate.

2. Rotor is now in the full top position. Mark this position

on the hub of the meter (Point A), Figure 34.

• Also mark Allen wrench for reference (Point B),

Figure 34.

Figure 34

Loading...

Loading...