Page 18 • MN01029 Issue/Rev. 0.5 (6/11)

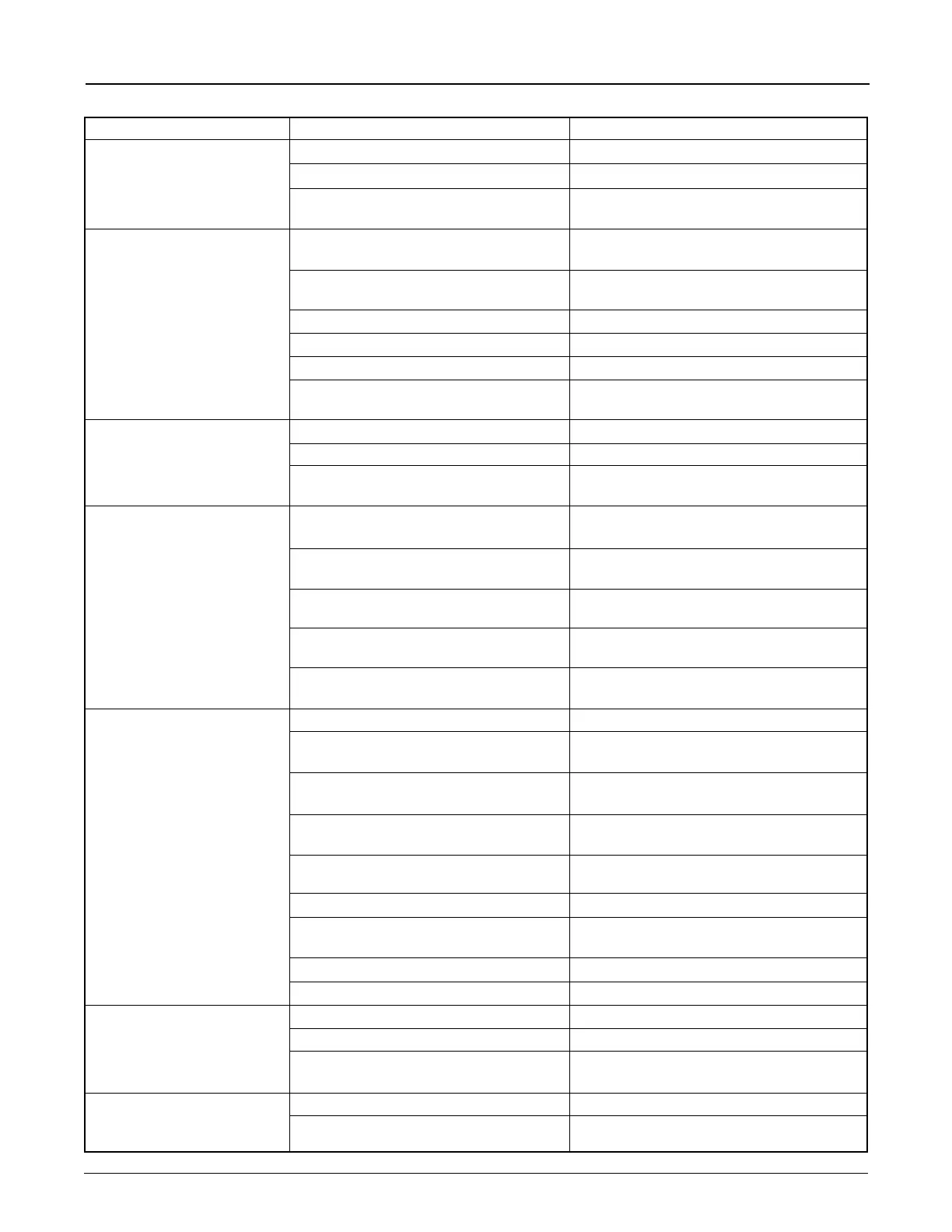

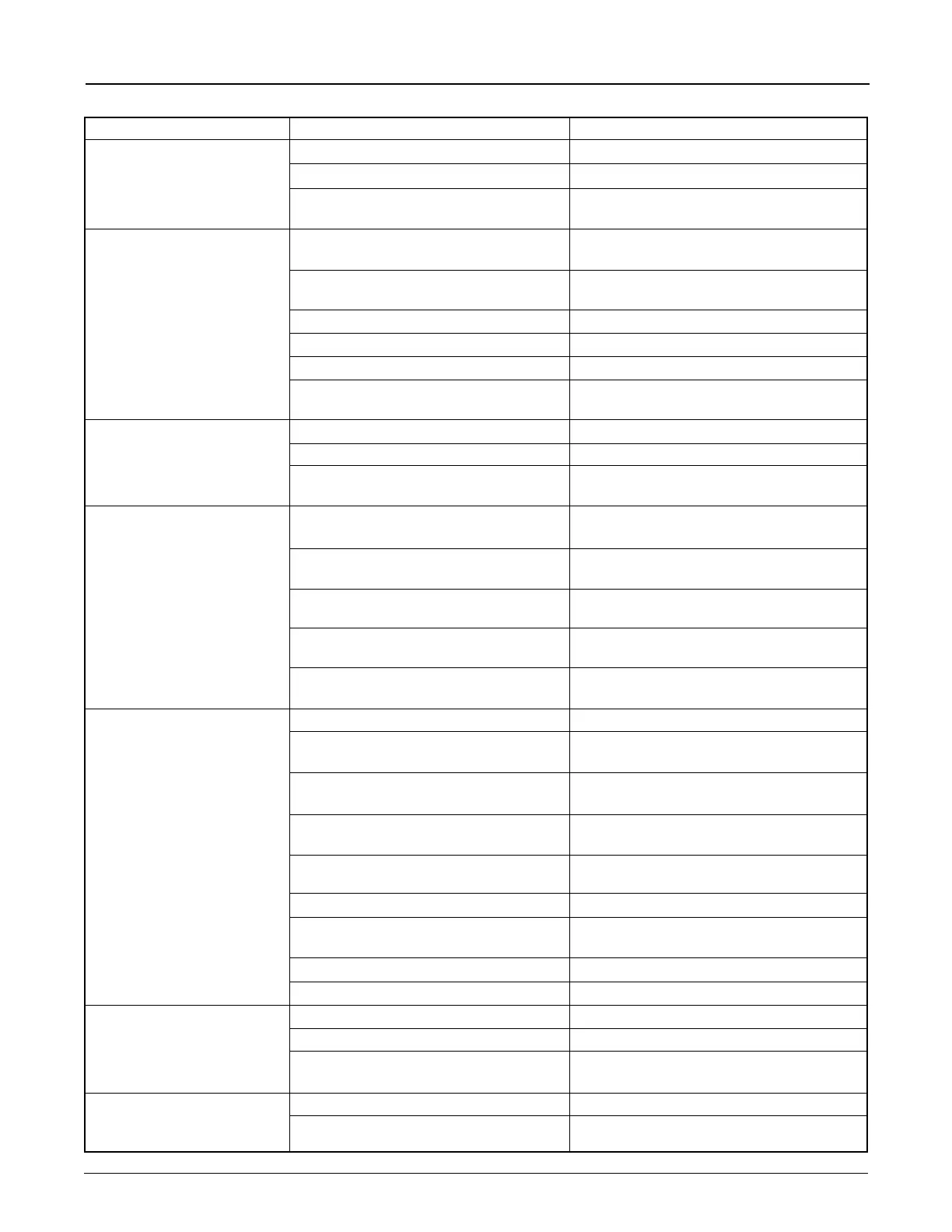

Problem Cause Remedy

Air passing through meter. Check air eliminator.

Calibrator out of adjustment. Readjust calibrator. See MN01028, Pg. 4.

Leakyvalveinproversystem(during Repairprovervalveandreruntest.

test run).

Mechanical friction in meter. Check all meter clearances. See Pgs. 12

through 13. Check bearings for tightness.

Binding or misalignment in driven Inspect accessories. Repair or replace.

accessories.

Loosegeartrainorslippingdrives. Repairorreplace.

Calibrator out of adjustment. Readjust calibrator. See MN01028, Pg. 4.

Oversize clearances in meter. Check meter clearances. See Pg. 12.

Product being eliminated through See below.

vent line.

Air eliminator cylinder seal damaged. Replace cylinder seal.

Air eliminator float ruptured. Replace float.

Foreign particles on cylinder sealing Clean sealing surfaces.

surfaces.

Linkageoutofadjustmentbetween Adjustlinkagecorrectly.

set-stop counter and valve.

Improper setting of “Minimum Setting” See Pushbutton Set-Stop Counter

in set-stop counter. Service Manual.

Mechanical obstruction in valve. Disassemble and remove obstruction.

Inspect valve internals for damage.

Defective pushbutton set-stop See Troubleshooting Section in Push-

counter. button Set-Stop Counter Service Manual.

Plugged orifice. Check orifice in upper piston of P-2 or

PG-2 Valve (pressure system only).

Strainer clogged. Clean strainer. Replace if necessary.

Butterfly valve in air eliminator Repair or replace.

restricting flow.

Back pressure or manual valves do Disassemble and inspect for foreign

not open. particles and/or defects. Repair.

Mechanical obstruction in meter. Disassemble and remove obstruction.

Inspect meter internals for damage.

Pump not operating (pressure Inspect pump for mechanical or elec-

system). trical defects. Replace if necessary.

No product. Supply product.

Air being eliminated from product. Normal - product flow automatically is

restricted during air elimination.

Pump undersized. Replace with pump of sufficient capacity.

Pump not operating properly. Check pump.

Linkageoutofadjustment. Adjustlinkagecorrectly.

Defective main seat seal in valve. Replace seal.

Foreign matter holding main valve Disassemble valve and remove foreign

seat open. matter. Check seal for damage.

Drive coupling defective. Replace.

Internal problems. See Veeder Root Service Manual.

Section 4 – Troubleshooting Table

Over-registration (register-

ing more volume than pass-

ing through meter).

Under-registration (register-

ing less volume than pass-

ing through meter).

Product being eliminated

through vent line.

System fails to shut off

properly after delivering

preset quantity.

Restricted product flow

through meter.

System leaks after shutdown.

Largenumeralcounteror

ticket printer not operating

satisfactorily.

Loading...

Loading...