Issue/Rev. 0.5 (6/11)

MN01029 • Page 15

Section 3 – Meter Repairs

Replacing Adjusting Stem Assembly

The adjusting stem assembly may be replaced as a unit

or it may be disassembled and repaired. If disassembly

ofadjustingstemisdesired,refertoSmithPartsList

for part numbers of replaceable items. See Page 21 for

applicablePartsListNo.foreachmetertype.

Toreplaceassembly:

1. Remove knob cover.

2. Unscrew the two screws securing adjusting stem

assembly to meter cover and remove assembly,

Figure 53.

•Noteadjustingstemadapter.Besurethisadapter

is in position when new or repaired adjusting stem

assembly is installed.

Replacing Packing Gland

Note: Meter must be drained and all pressure relieved

before beginning this procedure.

The packing gland may be replaced without having to

removethemetercover.Toreplacepackinggland:

1. Remove all accessories and calibrator from top of

meter.

2. Remove cotter pin and drive washer, Figure 54.

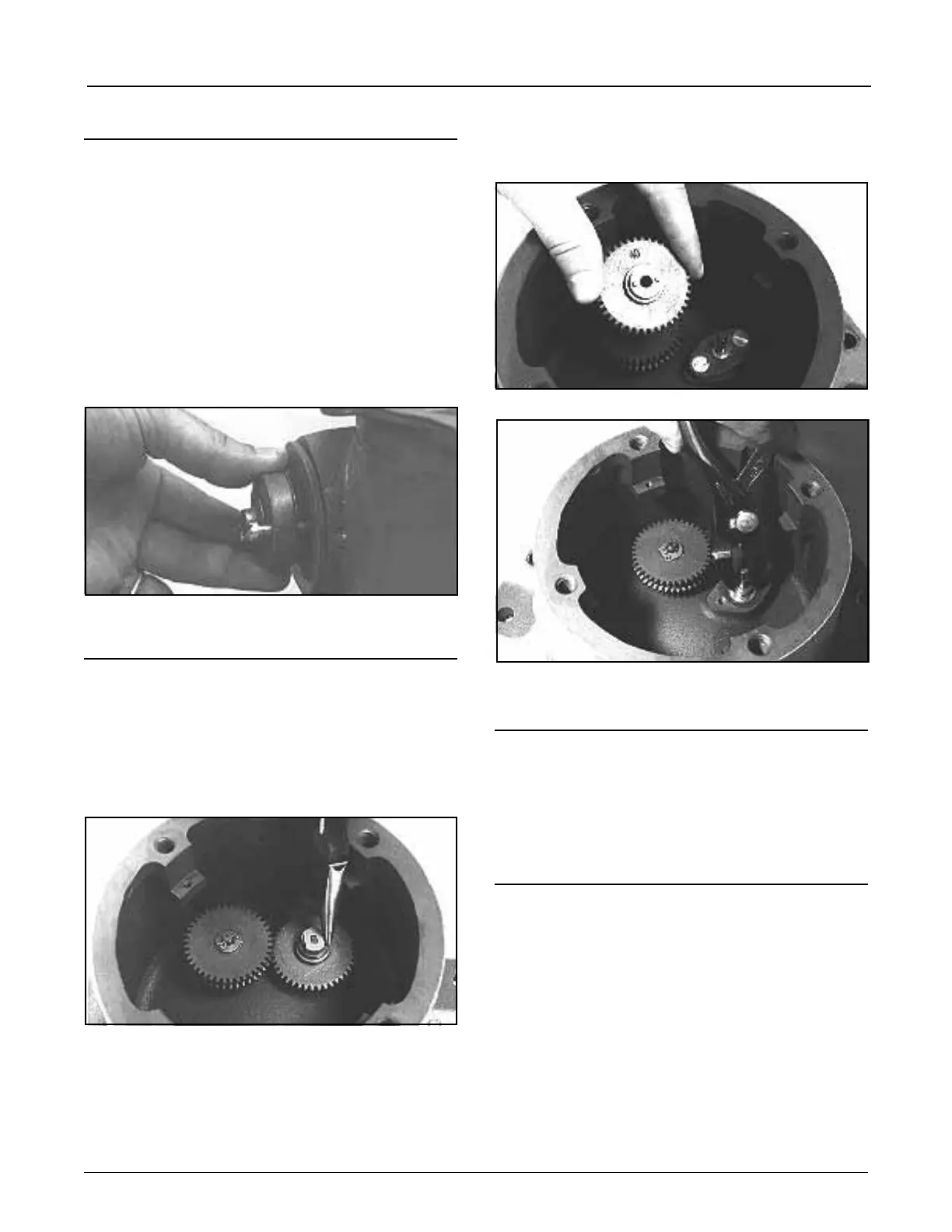

3.Liftsinglepiniongearfromjackshaft,Figure55,and

remove packing gland flange.

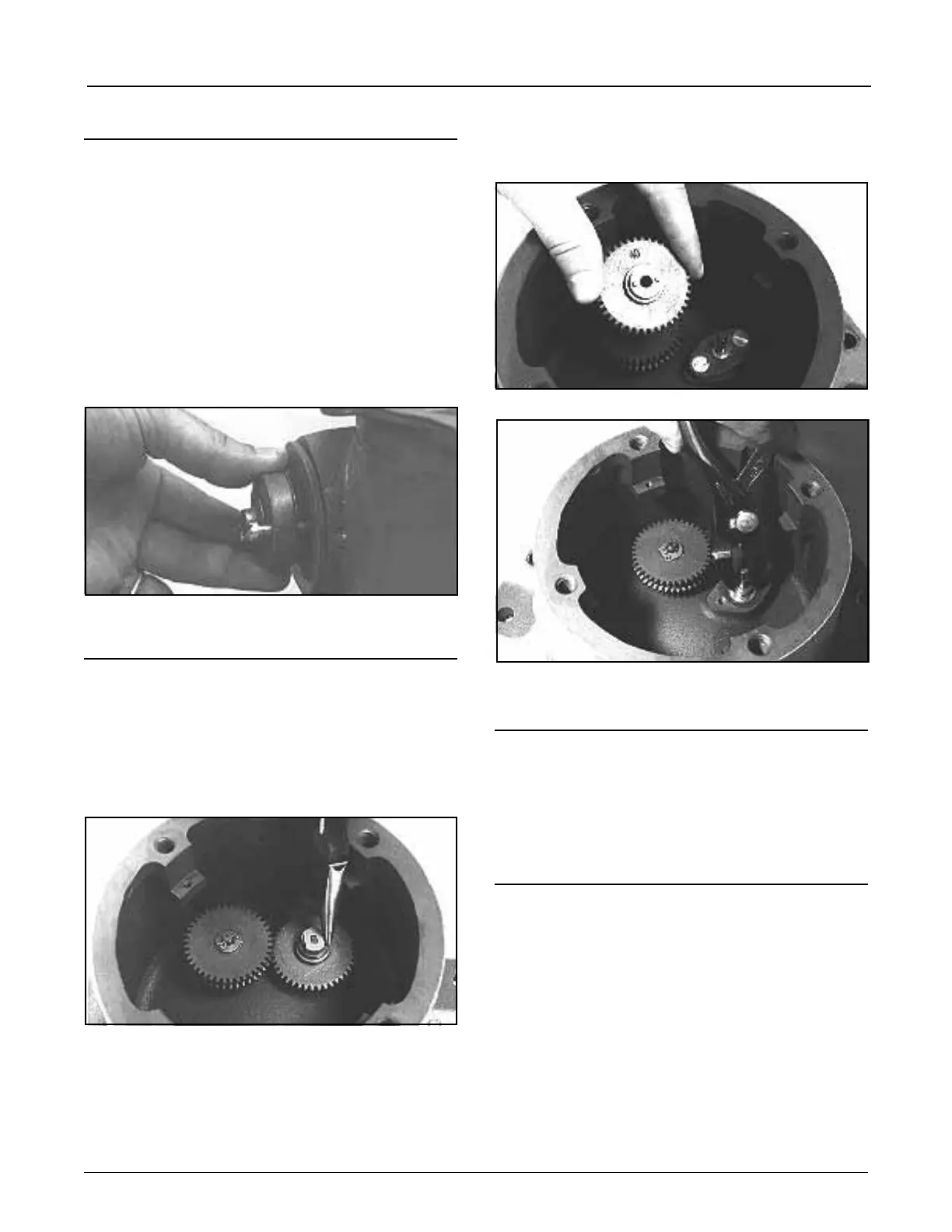

4.Liftpackingglandfromcover,Figure56.

•Ifpackingglandisdifculttoremovewiththengers,

use a pair of pliers as shown in Figure 56.

5. Install new packing gland and reassembled items

removed in Steps 1, 2, and 3.

•Replacepackingglandgasket,Figure56,ifrequired.

Figure 55

Installing New Rotor

Should it become necessary to replace a rotor assembly,

refer to the Clearance Checks Section of this manual

and perform all necessary checks to fit new rotor into

housing. After rotor is fitted to housing, refer to Adjusting

Rotor End Clearances, Page 9.

Replacing Blade Assembly

1. Install appropriate spider (see Suggested Tools and

Fixtures, Page 2) and perform clearance checks as

outlined in Clearance Check Section of this manual.

2. In most instances, clearances with new blades will

befoundtobetooclose.Whenthisisthecase,the

complete rotor assembly must be removed and the

blade ends dressed down.

•Figure 57 shows the proper manner in which to

accomplish this filing operation. Use a vise with soft

jaws or otherwise properly protect the blade held

by the vise.

•A Vixen (babbit metal) le is recommended for

aluminum blades. A mill coarse file should be used

on cast iron blades.

Figure 54

Figure 56

Figure 53

Loading...

Loading...