Page 8 • MN01029 Issue/Rev. 0.5 (6/11)

next level assemblies (rotor gear plate or rotor

subassembly) be procured with bearings already

installed, or capabilities must permit epoxying

bearings in precise alignment.

6. The blades are matched to their own slots. Therefore,

before removing blades from the rotor, the blades and

rotor slots must be matched-marked.

•Figure26showsonemethodofmarkingbladeand

rotor. Using a marker, make identical notches (in

this case, two) on the back end of the blade and on

rotor area next to blade slot. It is unnecessary to

mark opposite paddle of blade for obvious reasons.

7. The lower blade assembly can now be removed.

•Because of the position of the rollers, it will be

necessary to maneuver the blade assembly out of

the rotor.

•Handlebladecarefullysothatedgesofbladesare

not damaged.

•Ifrollersrequirereplacement,refertoPage12for

replacement procedure.

•SeeFigure27foralternatebladeandrotorbearings.

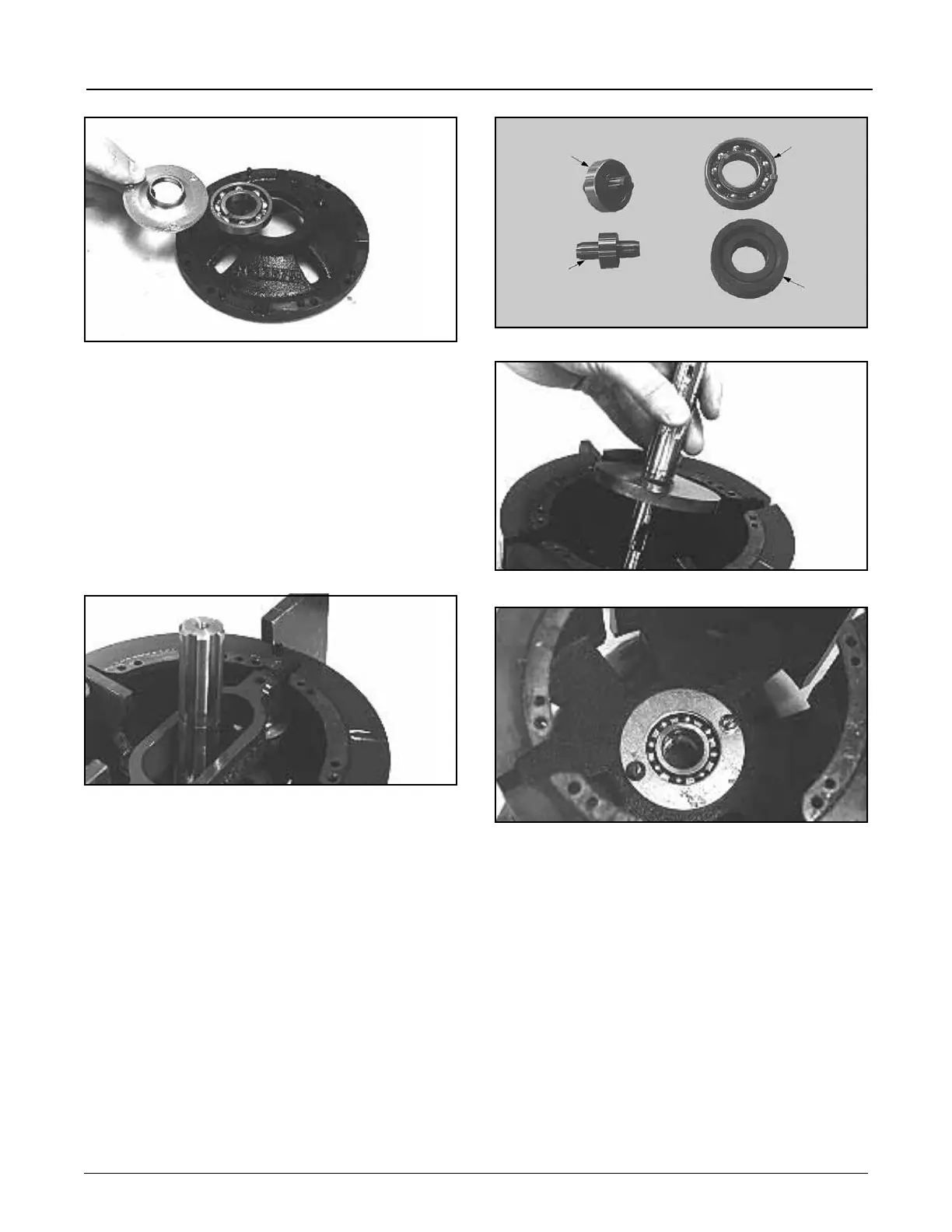

8. The cam and shaft assembly is lifted out of the rotor,

Figure 28.

•Thecamissecuredtotheshaftbyakey,Figure28.

Figure 25

Standard Blade

Bearing and Pin

Tungsten Carbide

Blade Bearing

and Pin

Standard Rotor

Bearing

Tungsten

Carbide

Rotor

Bearing

Figure 27

Section 1 – General Information and Description (continued)

Figure 26

Figure 28

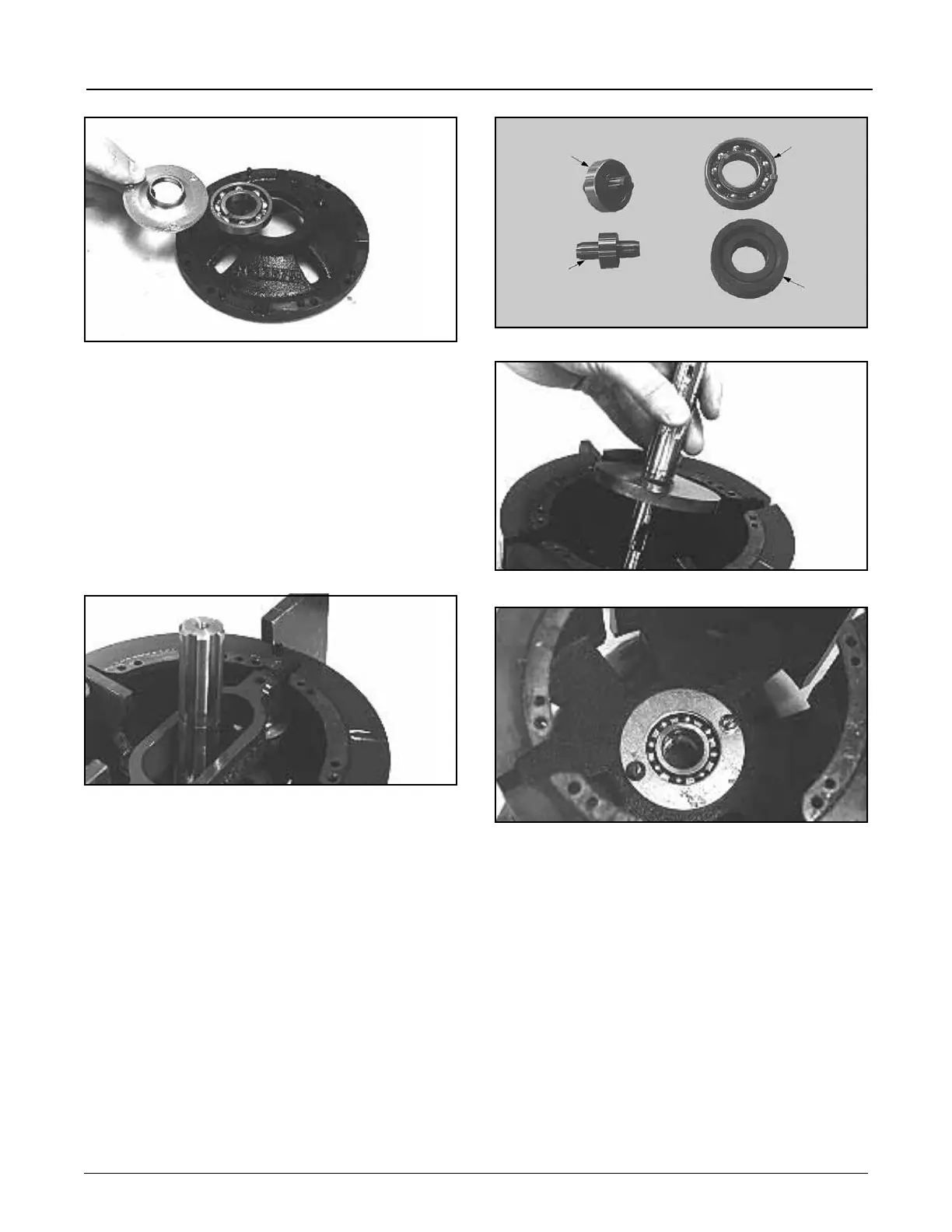

Figure 29

9. Mark upper blade assembly and rotor and remove

blade assembly.

•Usedifferentsetofmarksthanusedonlowerblade.

•Notebearingkeyonrotorbearing,Figure29.This

key is not bonded to the bearing and may fall off

after shaft is removed. Be sure this key is in place

when shaft is reinstalled. An application of vasoline

will aid in keeping the key in position.

10. Remove clamping ring, Figure 29, and rotor bearing.

Loading...

Loading...