Issue/Rev. 0.5 (6/11)

MN01029 • Page 7

4.Whenrotorassemblyisremovedfromthehousing,

turn it upside down and place it on a wooden block

or metal plate.

•Thewoodenblockorplatemusthaveaclearance

hole in the center for the shaft and must be high

enough to allow the shaft to clear the table. See Fig-

ure 1 for dimensions in constructing a wooden block.

•Ifrotorassemblyistobesetasidetemporarily,it

may be laid on its side. However, cardboard or other

suitable cushion should be placed under it to protect

the blades from damage.

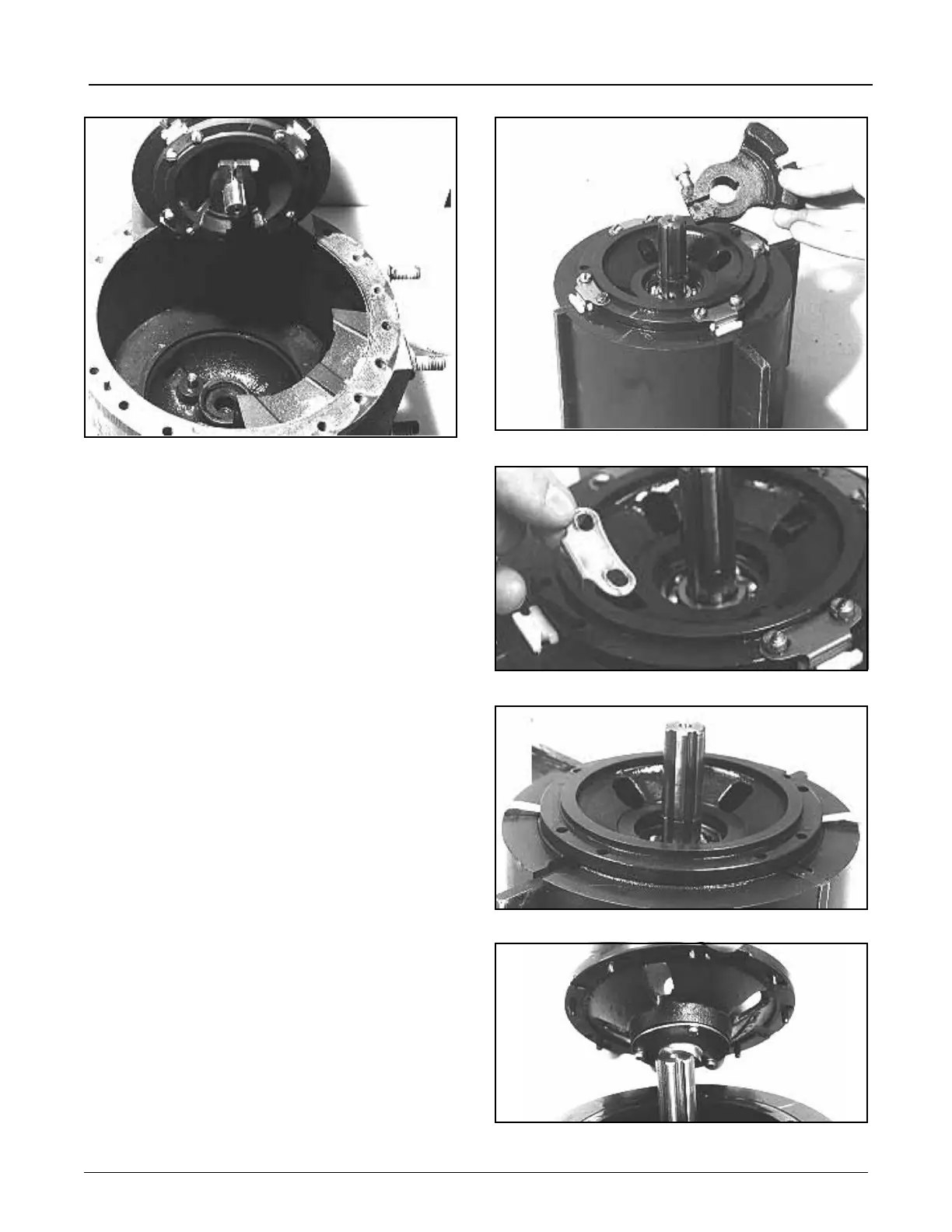

5. The block, Figure 19, can be separated from the

housing by removing the two bolts in the side of the

housing.

•When replacing the block, a sealant must be

appliedtothetwoblockretainingbolts(Master

Gasket by Loctite is recommended).This will

preventleakage.

Rotor Disassembly

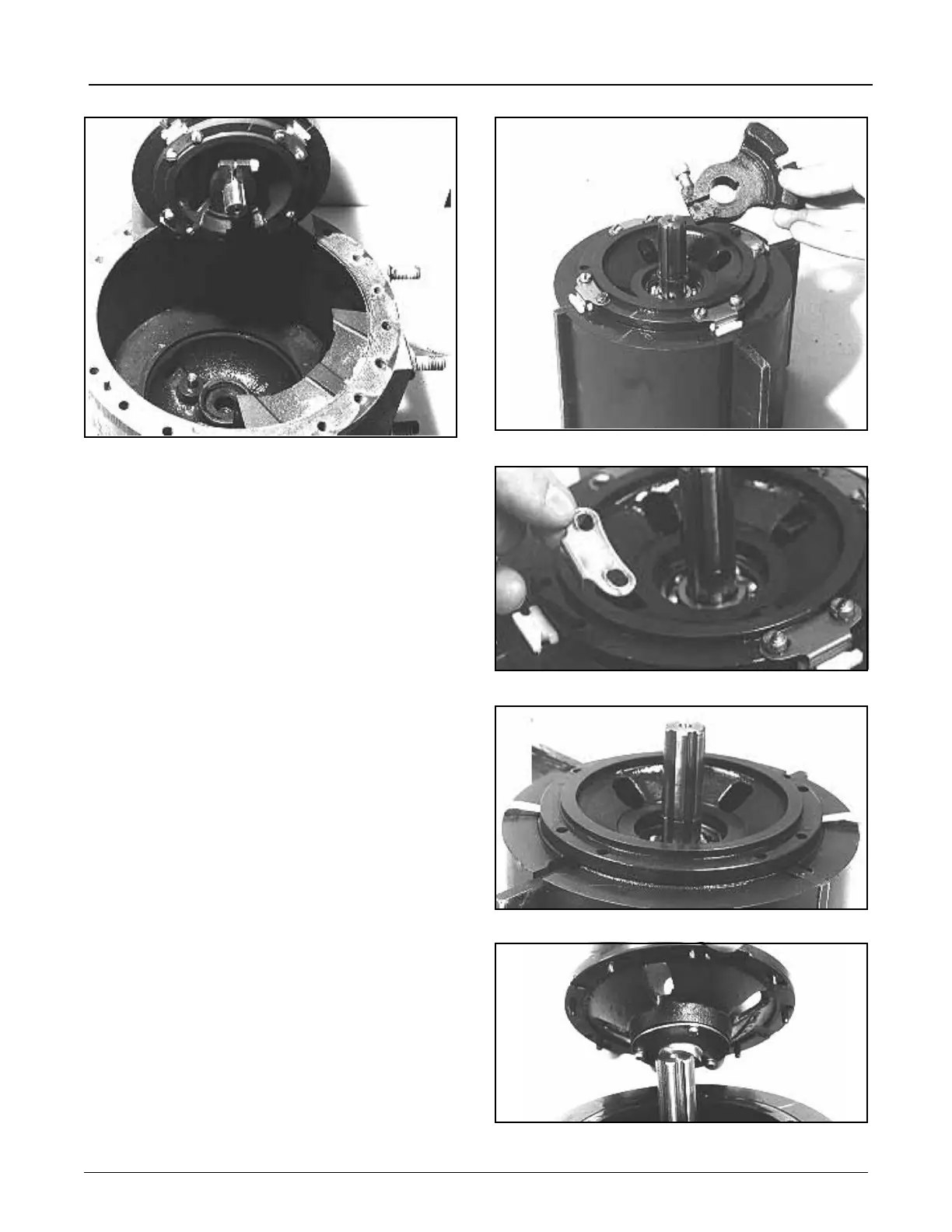

1. Using an Allen wrench, loosen locating arm screw

and pull locating arm from shaft, Figure 21.

2. Remove key and retaining ring from shaft, Figure 21.

3. Remove clamps and blade blocks, Figure 22, from

assembly.

4. Using two screwdrivers, pry off rotor cover, Figure 23.

• Slots are provided in the cover to accept the

screwdriver blades. Place screwdrivers opposite

each other and pry upward uniformly. Do not pry

downwardwithscrewdrivers,asdamagecould

occur to the top edge of the rotor body.

•Notelocatingpinsincover,Figure24.

5. The rotor cover consists of the cover, Marcel ring,

rotor bearing, and lower bearing shield, Figure 25. If

replacement of tungsten carbide outer radial bear-

ings is necessary, it is recommended that complete

Figure 20

Figure 21

Figure 22

Figure 23

Figure 24

Section 1 – General Information and Description (continued)

Loading...

Loading...