FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

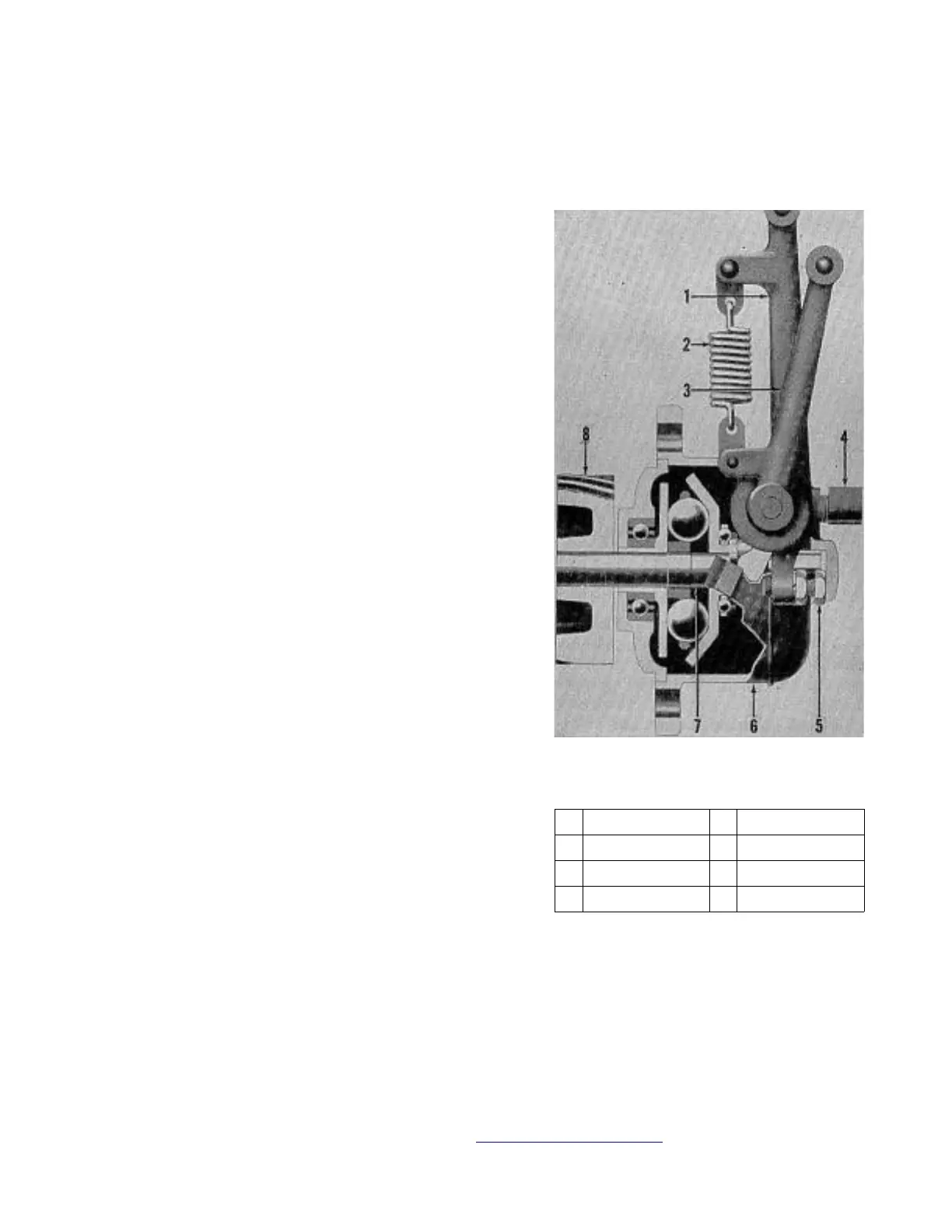

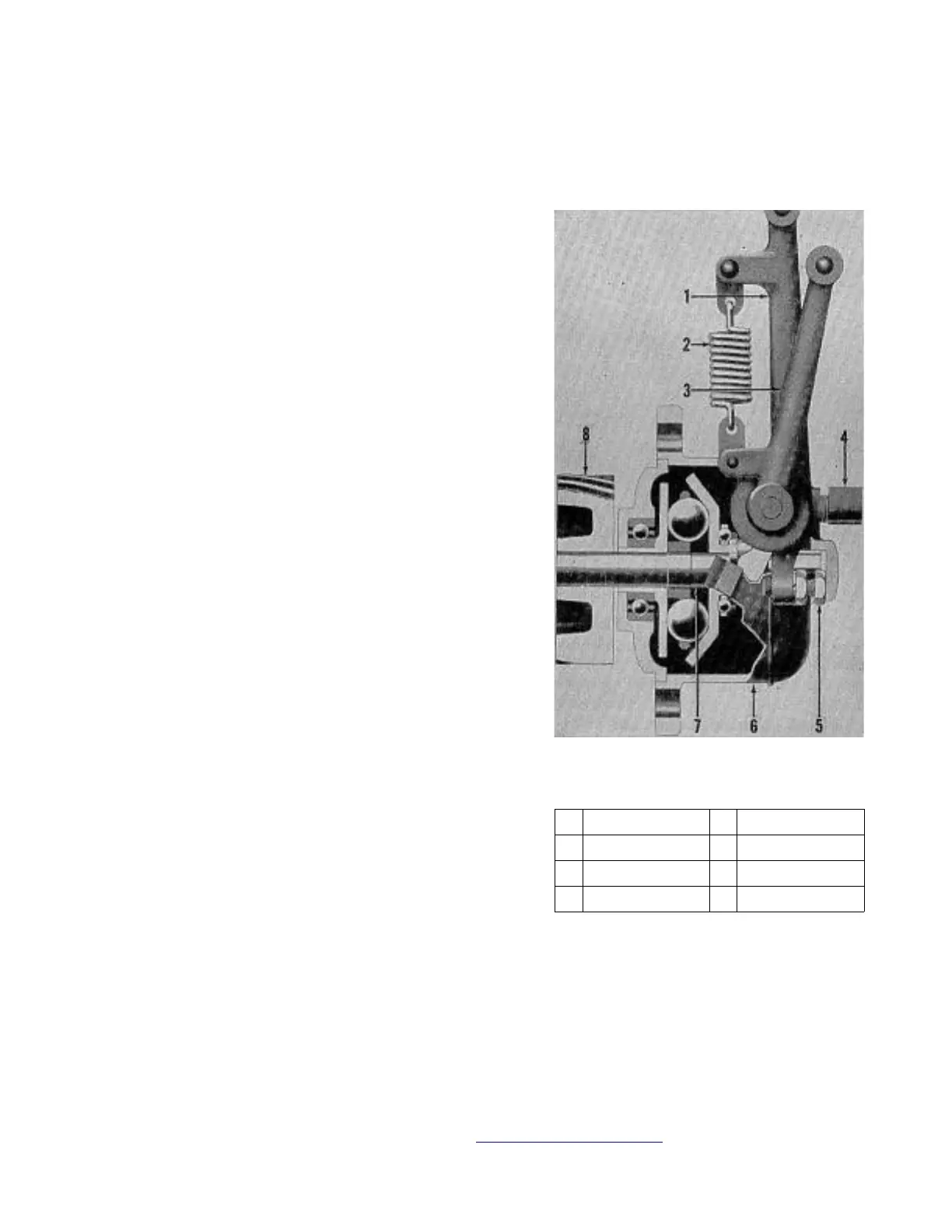

GOVERNOR

43. The governor, shown in Fig. FO-28 is a

variable speed, ball type, driven by engine

timing gears and interconnected with the throttle

linkage and carburetor throttle valve. Splash

lubrication is provided from timing gear case and

it is important that the large oil passage

opening in governor ball bearing carrier plate,

to be installed at top or up position to assure

proper lubrication. Further lubrication is

provided by an oil line which connects between

rear of governor housing and oil filter as shown

in Fig. FO29. Early model tractors were not

provided with this oil line but service parts are

available to permit this approved modernization.

44. ADJUSTMENT. The governor spring (2 Fig.–

FO28) should be a snug bit but should have no end

play and no pre-load. Spring may be adjusted by

bending the loop on the spring with pliers. Check

engine speed at Power Take-Off shaft or belt

pulley, after engine is warmed up. Correct

governed speed with hand throttle lever in last

quadrant notch or wide open is 727 to 800 PTO

shaft rpm, 2000 to 2200 engine rpm or 1358 to

1494 belt pulley rpm.

If crankshaft speed exceeds 2200 rpm or power

take-off speed exceeds 800 rpm with throttle

lever in last quadrant notch, turn in maximum

speed stop screw (Fig. FO28 - 5) until speed is

correct. If engine overspeeds before hand

throttle is wide open, adjust model 2N 9N–

linkage by holding throttle shaft lever at “A”,

Fig. FO30 and bending linkage until speed is

correct, or by lengthening governor link rod on

model 9N, as shown in Fig. FO31.

Connect/Report Errors – jcchapster@gmail.com

Fig. FO28 Novi ball type –

governor used on models 2N-8N-9N

tractors.

1. Inner lever 5. Stop screw

2. Spring 6. Housing

3. Outer lever 7. Flyball unit

4. Oiler elbow 8. Drive gear

Loading...

Loading...