FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

this condition is incorrect adjustment of quadrant. Refer to paragraph 99 or 101.

PUMP R&R AND TEST

Models 2N-8N-9N

114. TEST PUMP. To check pump operating pressure when pump is installed, proceed

as follows: Remove hexagon head (1/2 x 20) cap screw (14-Fig. FO92) located at

right hand corner of pump base and in its place connect a pressure gauge of not

less than 1700 and not more than 2500 psi capacity. With the lift arms secured in

the full lowered position or weighted to prevent lifting, move the touch control

lever to the top position on the quadrant. The relief valve should open at a gauge

pressure of not less than 1600 psi.

If the pump does not deliver the

expected minimum pressure of 1600

pounds per square inch, check for a

faulty safety (relief) valve (30). To

check for this condition remove either

inspection cover from sides of rear

axle center housing. With the pump

running, there should be no visible

oil turbulence in the vicinity of the

safety valve. If turbulence is

present, remove the relief (safety)

valve and install a new one.

If the safety valve is considered to

be in operating condition by the

preceding check, and the expected

pressure is not obtained, the pump,

cylinder, and/or high pressure oil

tube is at fault. A visible oil spray

in the pump compartment of the rear

axle center housing indicates leakage,

the location of which can usually be

traced by visual inspection. If no oil

spray is evident, a further check

involving removal of the pump will be

necessary.

Connect/Report Errors – jcchapster@gmail.com

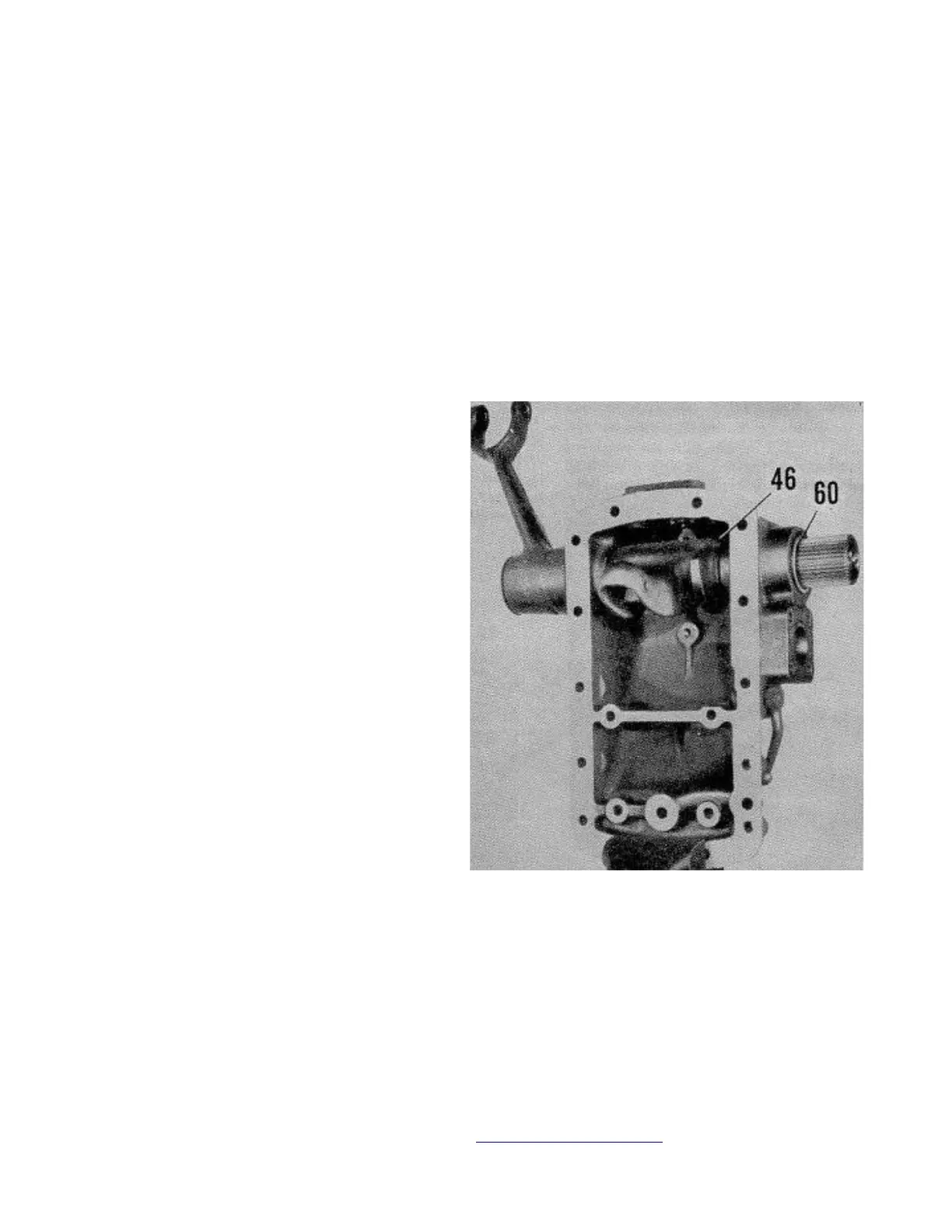

Fig. FO91 - Model 8N lift cover showing

first step in reassembly procedure.

Loading...

Loading...