6362

Bike storage

Between trips, keep your bike in a place with normal humidity, protected from sun and rain.

Use special detergents to clean the bike frame and parts. Improper use ofcleaning products can

damage the coating and material of parts.

Be sure to read this section of the Guide, since it is important to have an idea of how the various

parts and components of the bike are arranged and work.

If you have questions regarding the device and the functioning of any part, contact the seller

for clarication.

Attention! All assembly, tuning and repair work of the bicycle must be carried out by a

qualied bicycle mechanic at the place of purchase of the bicycle, in one of the author-ized

service centers or in a specialized bicycle workshop using professional equipment and tools

in compliance with the technological requirements of component manufactur¬ers (tightening

torques, see page 40) In case of independent and unqualied repair of the bicycle, the warranty

shall cease to be valid (see the «Warranty Information» section).

Tightening for threaded connections

Always use a calibrated torque wrench to tighten threaded connections. Before using the key,

be sure to read the manufacturer’s instructions.

The correct tightening torque for threaded connections is an important factor in your safety.

Always tighten all connections with the correct force.

5. TECHNICAL INFORMATION ASSEMBLY AND TUNING

OF THE BICYCLE

20–27

27–35

10–25

35–50

35–40

30–50

8–12

5–10

50–70

70–80

6–8

5–7

5–7

8–10

4–6

3–4

6–8

5–7

6–8

2–4

6–8

5–7

0.3–0.5

5–8 (М5), 10–14 (М6)

17–20

17–28

10–14

5–7

20–25

Torque Nm

Front axle nuts

Rear axle nuts

Axle cone locknuts

Threaded ratchet

Pedals

Connecting rod bolts

Gear Bolts (Bonks) Steel

Gear Bolts (Bonks) Aluminum

Cartridge Type Carriage

Adjustable carriage

Attaching Trigger Shifters

Front Clamp

Cable clip in front derailleur

Rear derailleur mount

Cable clamp in rear derailleur

Bolts of rollers of the back switch

Attaching the brake levers to the frame

Brake pads

Cable clamp

Brake disc (rotor)

Brake caliper

Hydraulic Line Fittings

Expansion tank cap screws

Threaded-type steering

Threaded steering

One bolt, 6 mm Allen key

Two bolts, 5 mm Allen key

Two bolts, 4 mm Allen key

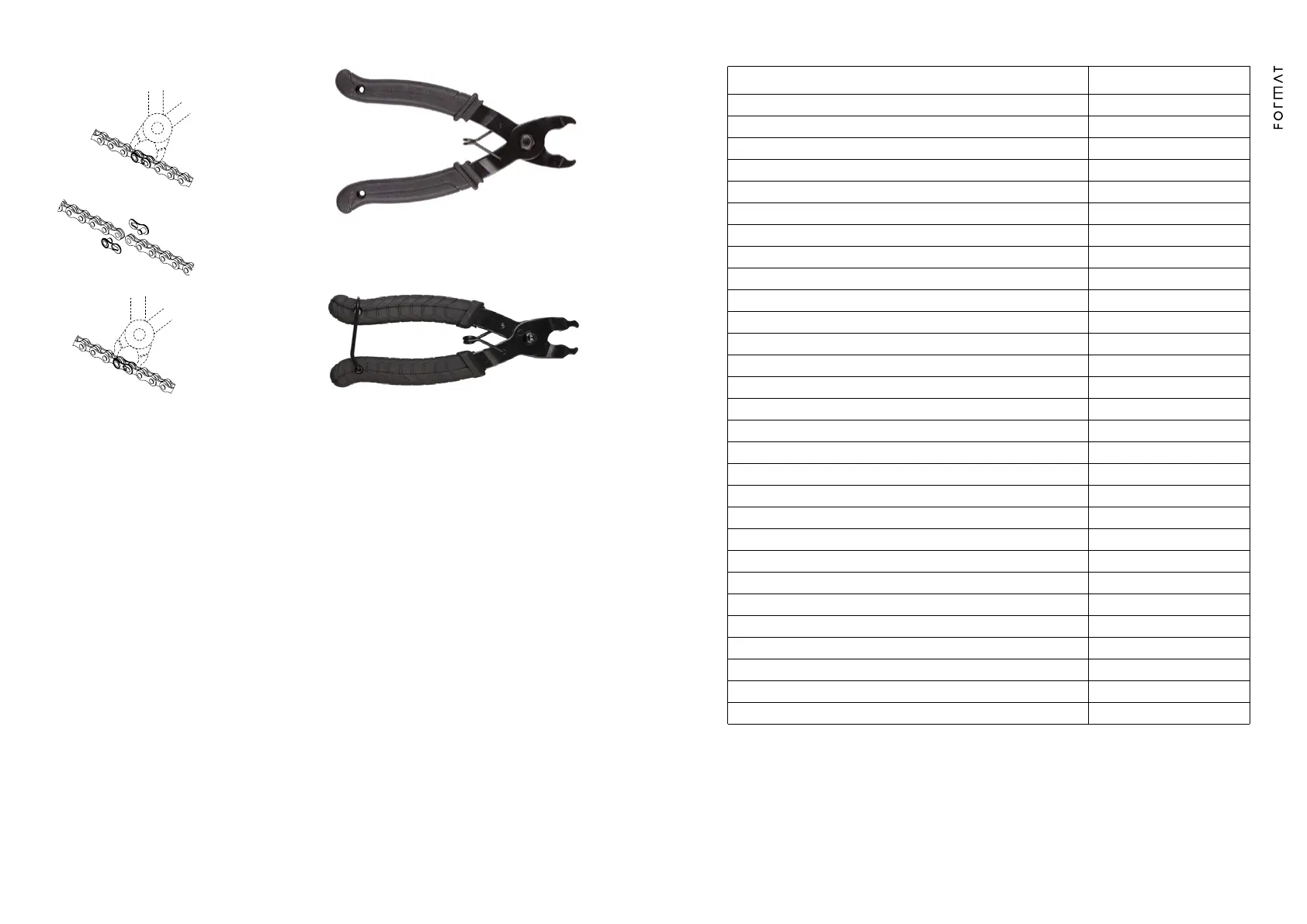

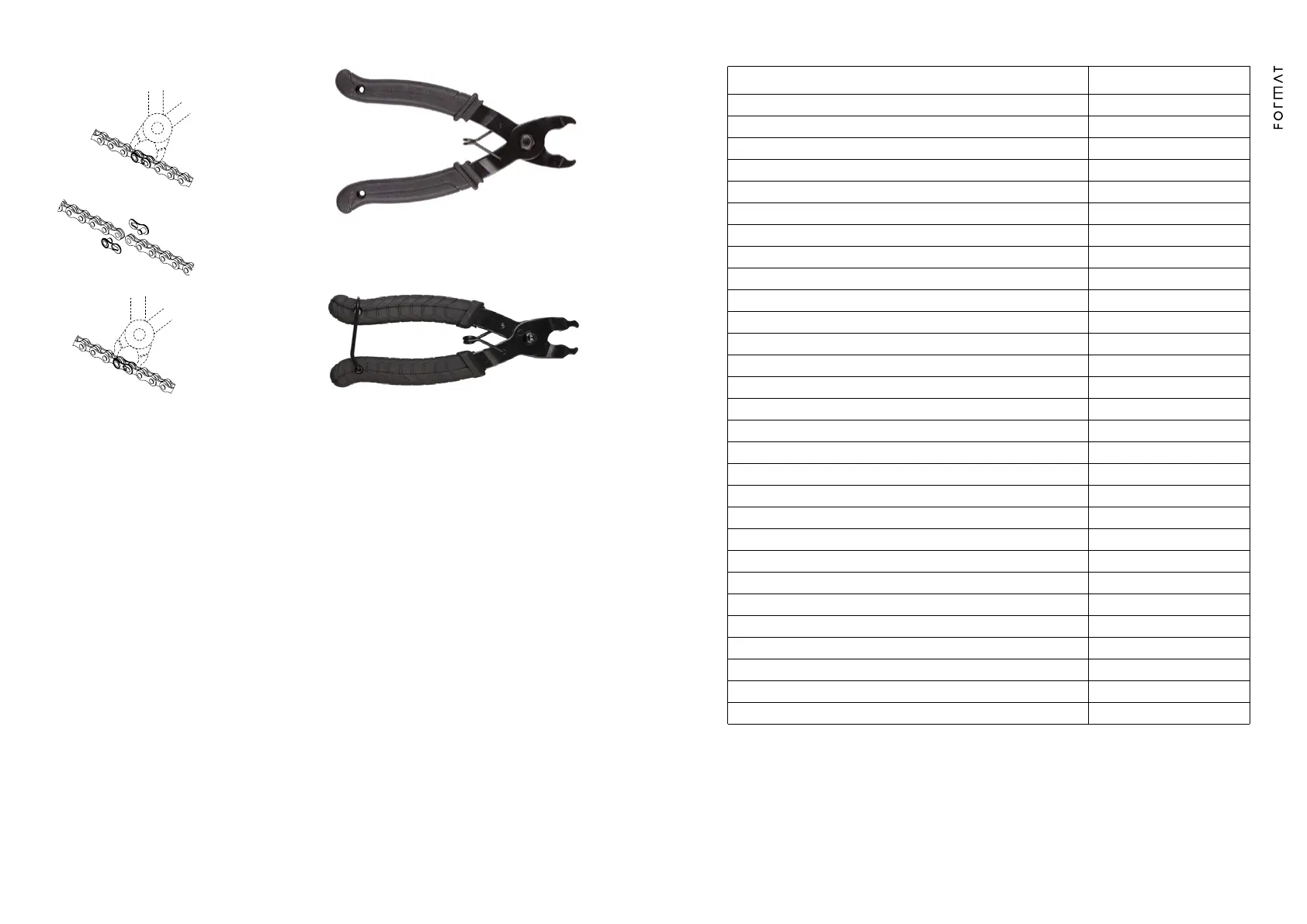

One stud with nuts, open-end wrench 13 or 14 mm

opening

the lock

closing

the lock

key to opening the lock

key to closing the lock

Loading...

Loading...