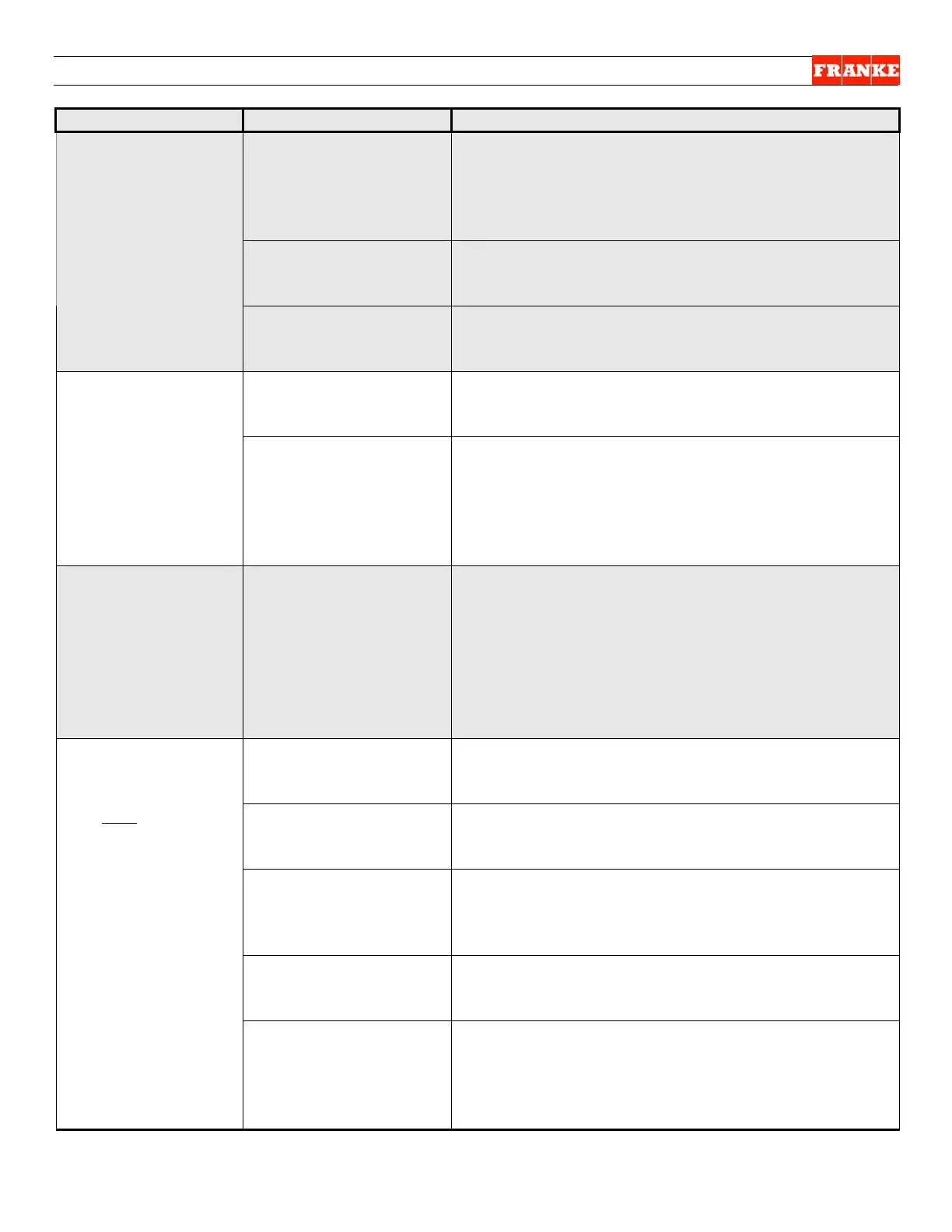

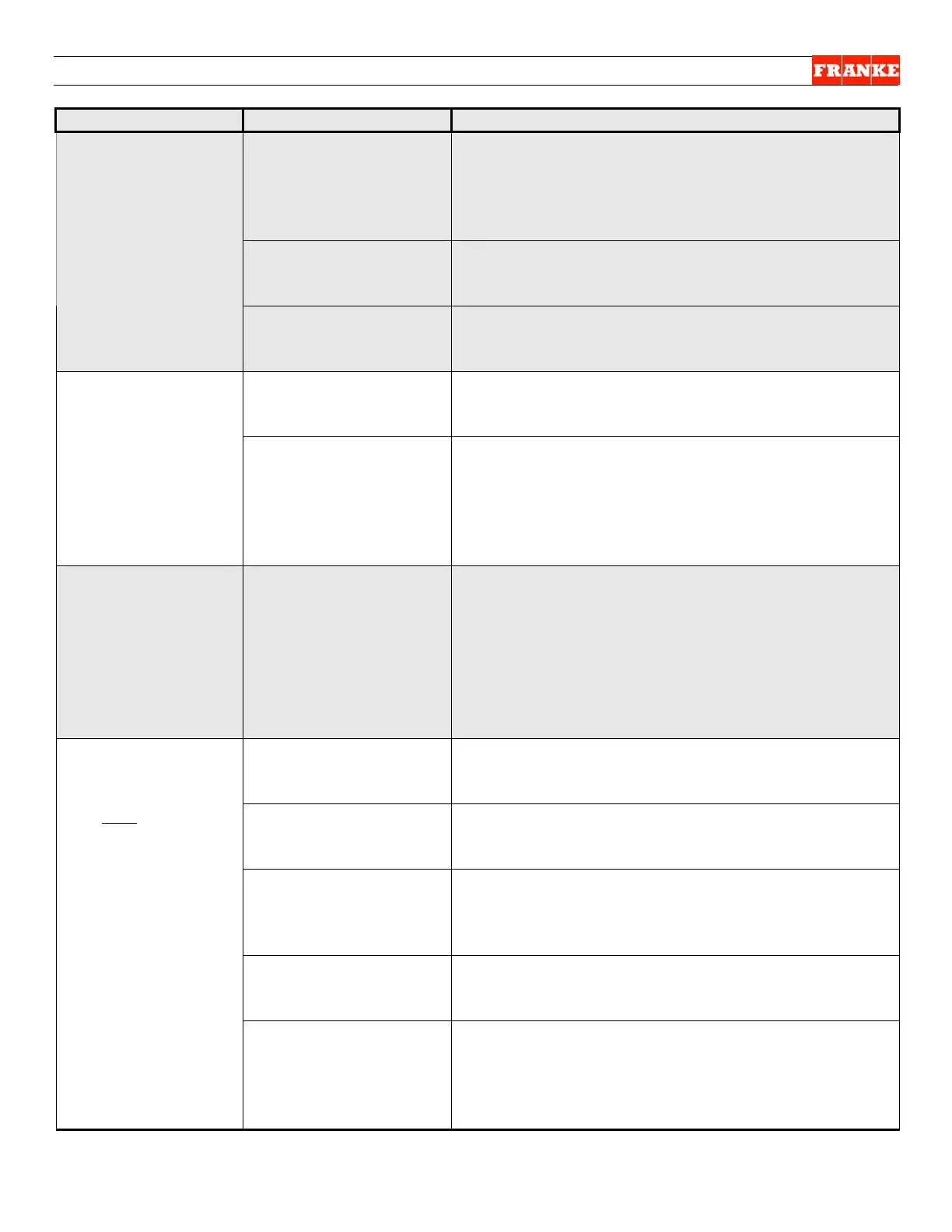

F3Dn Service Manual Advanced Troubleshooting Guide / Section 1.3

For Technical Support, Call 800-537-2653. Copyright © 2006 Franke, Inc. All rights reserved.

The Problem Possible Cause What To Check & Do

Does PC Control

Board have 24-Volt DC

power input from

supply?

No = replace Power Supply per Section 2.17; Yes

= check momentary +24-VDC and –24-VDC input to

Door Open Motor by removing basket and

reinserting it into dispense position. Did 24-Volt DC

signal occur?

Door Open Motor/Slide

Assembly?

Check Slide Assembly for binding components. If

OK = replace 24-Volt DC Door Open Motor per

Section 2.8

NO Fries

Dispensed:

[Dispense Doors Do

Not Open]

Continued…

PC Control Board? If 24-Volt DC Power, Door-Open Motor & Slide

Assembly are OK, replace PC Control Board per

Section 2.18

Door Closing Spring? Are doors partially open and easily moved by hand?

Yes = Replace Door Closing [Extension] Spring per

Section 2.10

Product Dispensing

Doors Remain

OPEN

Broken Link? Door

Open Sensor?

Check for broken link between door shaft blocks on

rear of unit. Yes = Replace using Spring & Link

Repair Kit P/N 18000798. No = Locate Door Open

Sensor and actuate flag on rear of unit. Is sensor

functioning? No = Replace Door Open Sensor per

Section 2.13

LOAD READY

Indicator LED On,

Doors Open…But

No Product

Dispensed

Load Cell Calibration? Remove upper back panel. Press Load Size button

and record “T=” numbers (5 digits) on LED display

on upper right of PC Control Board. Numbers

should vary by 50 – 100 counts when load size is

changed between: Small-Medium-Large. If not,

Load Cell Calibration may be incorrect (calibrated

for 0 weight); See Section 3.7 for Load Cell

Calibration procedure.

Hopper Low On Fries? Is LOW PRODUCT light on Operators Panel

flashing? Yes = Refill hopper with fries; No =

Continue…

Load Size Setting? Is LOAD SIZE selected correctly (Small, Medium or

Large)? Yes = Continue… No = Select correct load

size and restart this Lane.

Frozen Fries Bridge? Have French Fries formed a bridge inside hopper

(thawed and re-frozen)? Yes = Break bridge inside

hopper by gentle hand agitation of product. No =

Continue…

Product Chute

Alignment?

Is metal Product Chute assembled correctly inside

freezer? Yes = Continue… No = Reassemble F3Dn

parts correctly, per Operating Manual.

Wrong Load Size:

Too Few Fries

Load Cell Calibration? Recalibrate Load Cell per Section. 3.7. Did

recalibration procedure correct “too few fries”

problem? Yes = Return unit to service; No = See

Load Size Adjustment procedure in Section 3.4

[Note: Usually required at installation only.]

Loading...

Loading...