S70-101SM

Page 11

Frick XJS and XJF Rotary Screw Compressor

Service Manual

6. Thread T-wrench into slide stop piston (26, Figure 1-4);

remove slide stop piston with glyd-ring (10, Figure 1-4) and

o-ring (11, Figure 1-4). If glyd-ring and o-ring are to be

replaced, cut glyd-rings off of stepper piston using knife and

remove and discard o-rings.

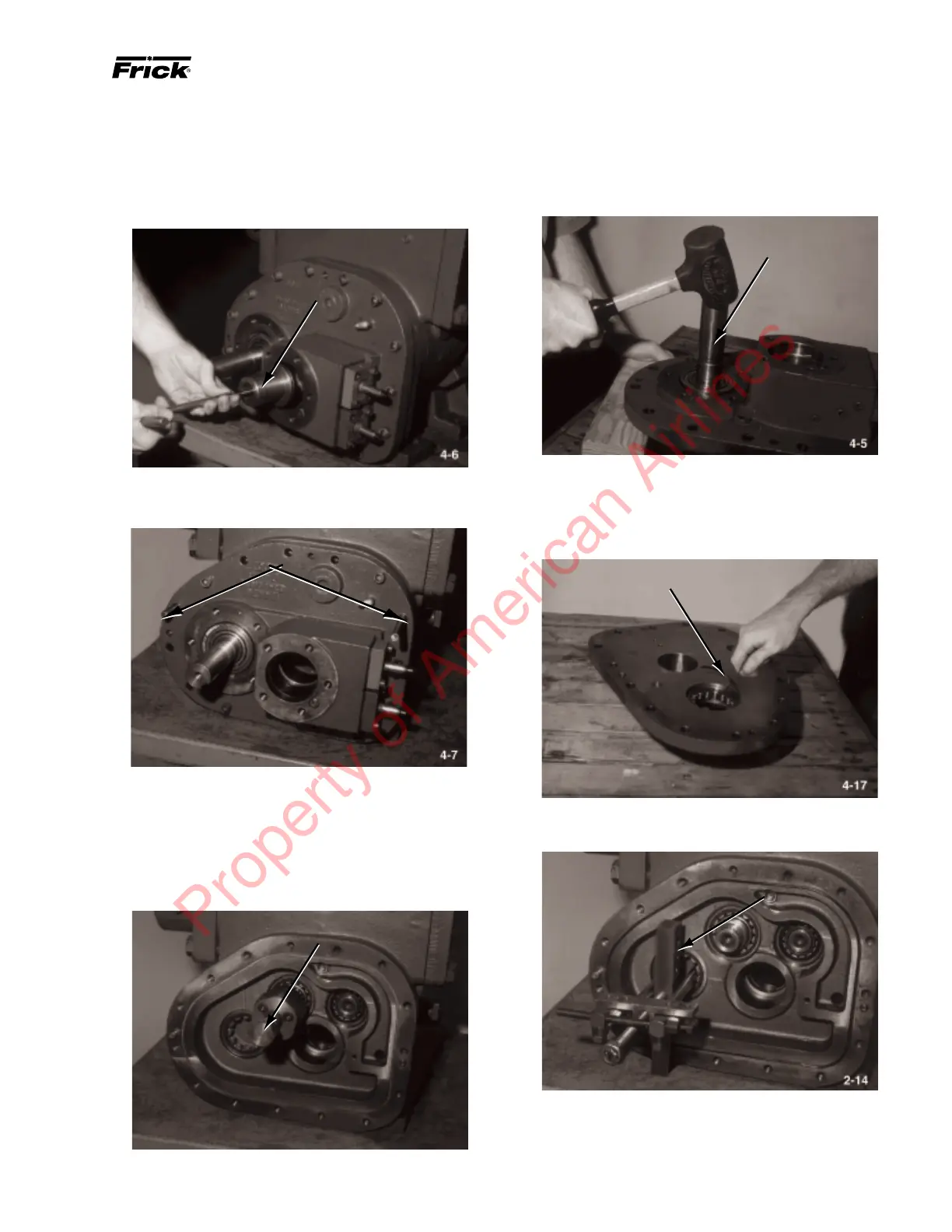

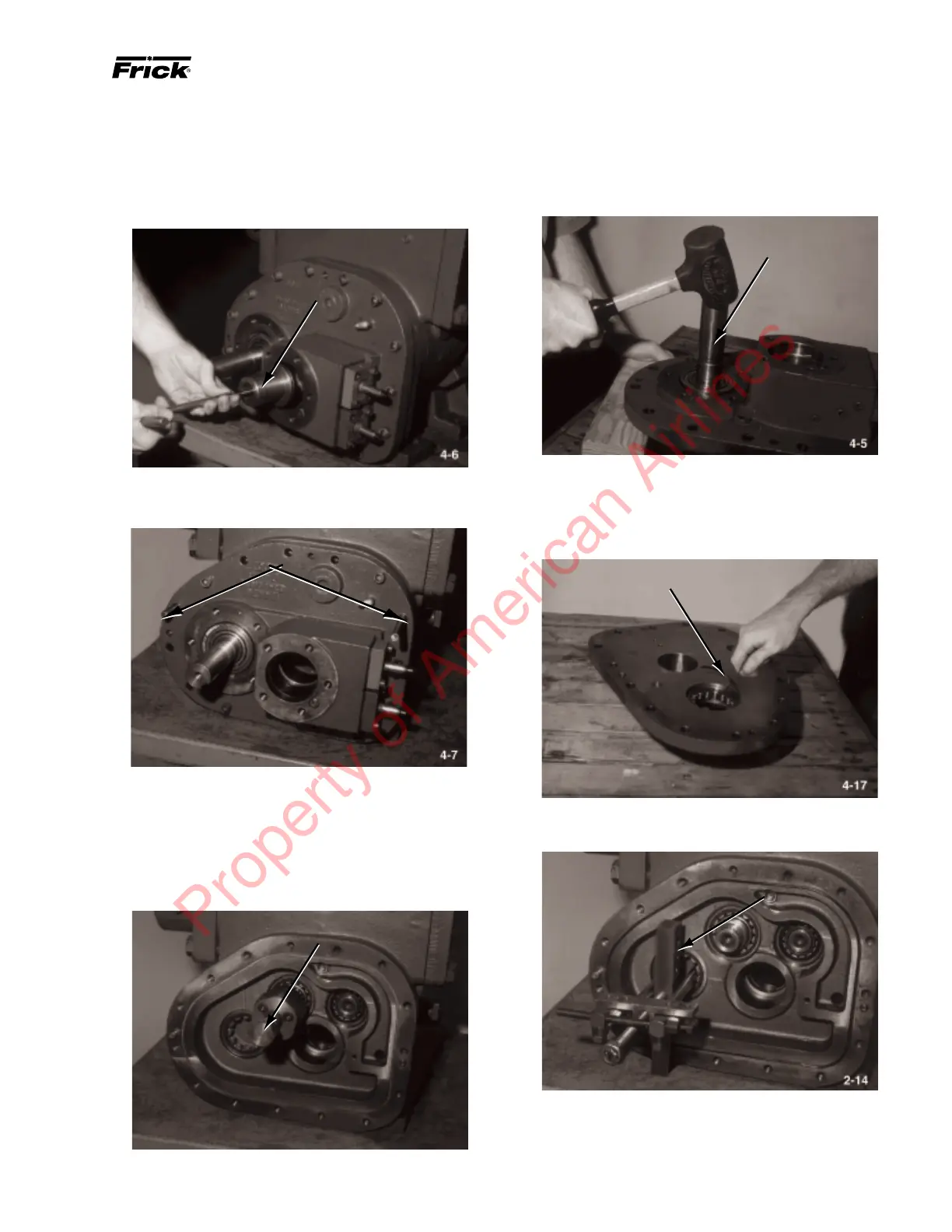

10.With gear cover elevated on wood blocks, remove jackshaft

and gear assembly from cover by tapping on outboard end of

jackshaft with rubber mallet; remove jackshaft, gear assem-

bly, and outboard section of inner race of four-point contact

ball bearing (9).

JACKSHAFT

11. Remove remaining section of four-point bearing from

gear cover.

12. Remove retaining ring (12) from gear cover using screw-

driver.

RETAINING RING

13. Remove outer race of roller bearing (11) from gear case

using Bearing Puller (Owattona Tool Co. p/n 943).

BEARING PULLER

NOTE: If replacement Jackshaft Kit is used, steps 14

through16 do not apply.

SLIDE STOP PISTON

7. Remove two capscrews (1) from opposite sides of gear

cover (2). Install two 12mm guide pins (3

1

/2-inches long).

8. Remove remaining capscrews from gear cover. Thread two

12mm capscrews into jacking holes in gear cover and spread

cover away from rotor casing (3). Hold on to jackshaft and

remove gear cover and o-ring (51).

9. Attach Pinion Gear Puller to pinion gear (14); remove

pinion gear from male rotor (47).

PINION GEAR PULLER

12MM GUIDE PINS

Property of American Airlines

Loading...

Loading...