S70-101SM

Page 14

Frick XJS and XJF Rotary Screw Compressor

Service Manual

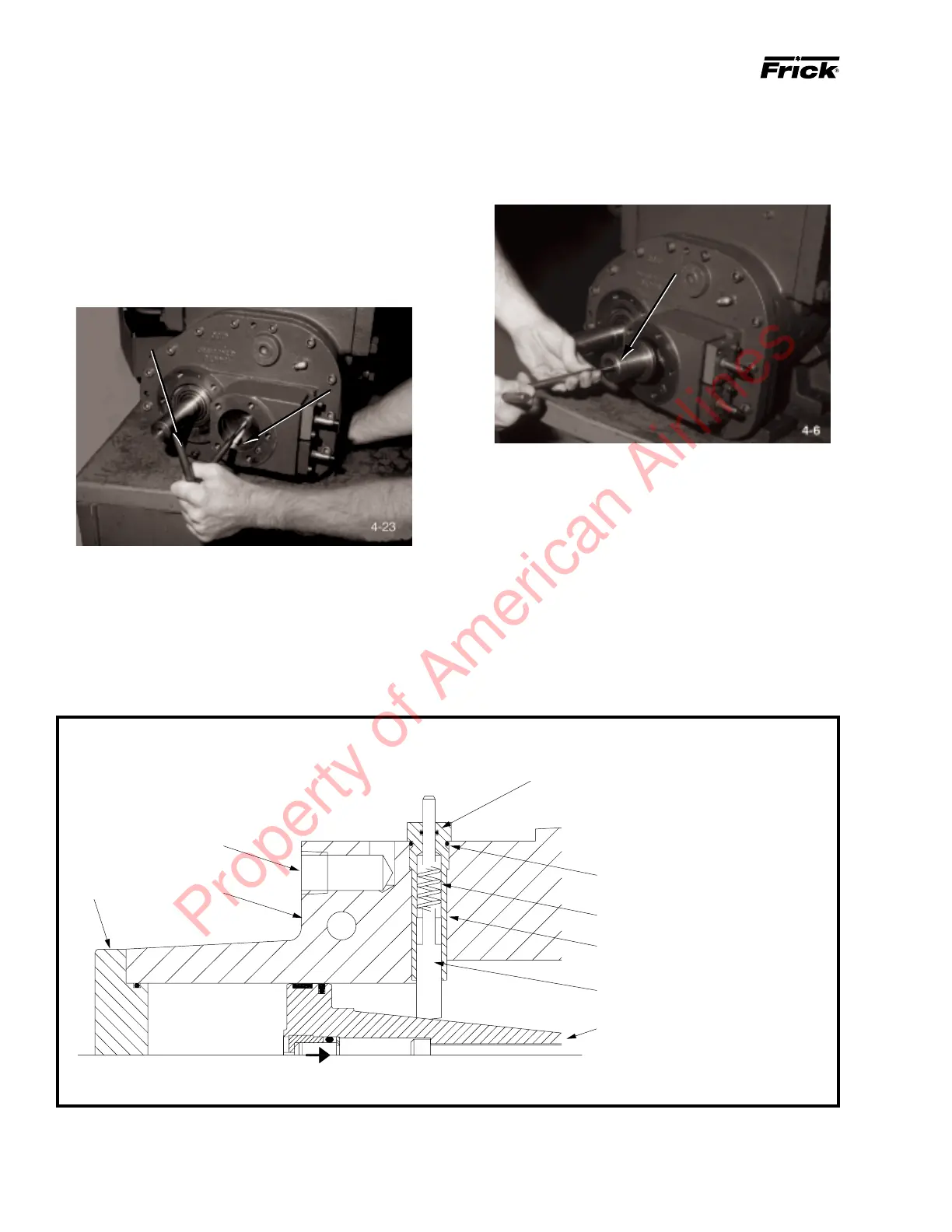

7. Thread T-wrench into slide stop piston (26); remove

piston with its glyd-ring and o-ring. If glyd-ring and o-ring

are to be replaced, cut glyd-ring off of slide stop piston and

remove o-ring with a knife.

SLIDE STOP PISTON

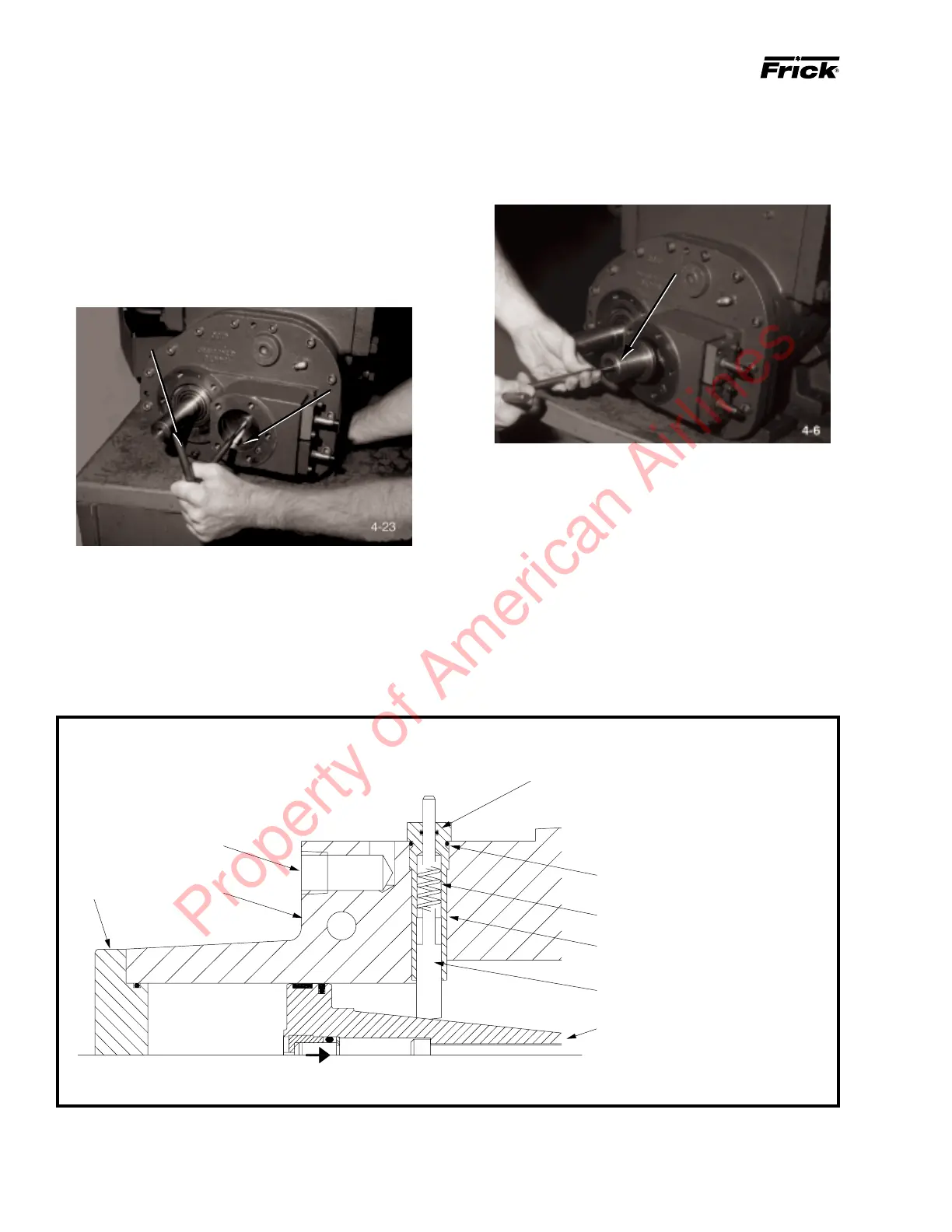

8. Remove compressor slide valve indicator position switch

cover; remove slide valve position switch.

9. Remove rod guide (5, Figure 1-5) with o-rings (2 and 3,

Figure 1-5), indicator rod spring (4, Figure 1-5), and indica-

tor rod (6, Figure 1-5); remove o-rings from rod guide.

10. Thread T-wrench into slide stop (25). While pushing in

against spring pressure, remove 8mm screw (threaded into

slide stop) through oil drain hole; remove slide stop.

Figure 1-5. Slide Valve Indicator.

1

9

2

3

4

5

6

7

8

1. Wiring Connection

2. O-Ring

3. O-Ring

4. Indicator Rod Spring

5. Rod Guide

6. Indicator Rod

7. Slide Valve Piston

8. Cylinder Cover

9. Discharge Casing

4. Place suitable drain pan under slide stop cover (30); remove

capscrews (7, Figure 1-2) securing slide stop cover to gear

housing (2). Remove slide stop cover and o-ring (32).

5. Thread 8mm T-wrench into stepper piston and push piston

in against spring force. With finger through oil drain hole,

push in against spring force and feel along bottom of slide

stop. When threaded hole in slide stop is located, insert an

8mm screw through oil drain hole and thread into slide stop.

STEPPER PISTON

8MM T-WRENCH

6. Remove stepper piston with its glyd-rings (10 and 28) and

o-rings (11 and 29). If glyd-rings and o-rings are to be

replaced, cut glyd-ring off of stepper piston and remove o-ring

with a knife.

Property of American Airlines

Loading...

Loading...