S70-101SM

Page 21

Frick XJS and XJF Rotary Screw Compressor

Service Manual

24. Install bearing spacer (32) over male rotor shaft.

inner race of roller bearing and inner race of ball bearing. If

clearance is greater than .003-inch, install shims in casing

bore

between roller bearing outer race and ball bearing outer race.

NOTE: Shim thickness is determined by amount of rotor

movement beyond the .0015 to .003 specifications.

Example #1

Measured end clearance = .005 inch

Desired normal end clearance = .002 inch

Desired shim size (location) = .003 inch between

outer race

Example #2

Measured end clearance = .0005 inch

Desired normal end clearance = .002 inch

Desired shim size (location) = .0015 inch between

outer race

Example #3

If end clearance is .000 inch, begin by placing .001

inch shim between inner races to extablish move

ment of the rotor.

NOTE: Installing shims will necessitate removal of dis-

charge casing. (Refer to steps 8 through 15 of para-

graph1.4.1.)

21. After attaining proper clearance, use drift tool to bend one

tab of lockwasher on end of female rotor shaft into one of the

recesses of locknut. This secures locknut in place and

prevents

it from turning on rotor shaft. Always use new

lockwashers,

never reuse lockwashers removed during disassembly.

22. Remove locknut (36), lockwasher (35), Spacer Tool, and

bearing spacer (32) from male rotor shaft.

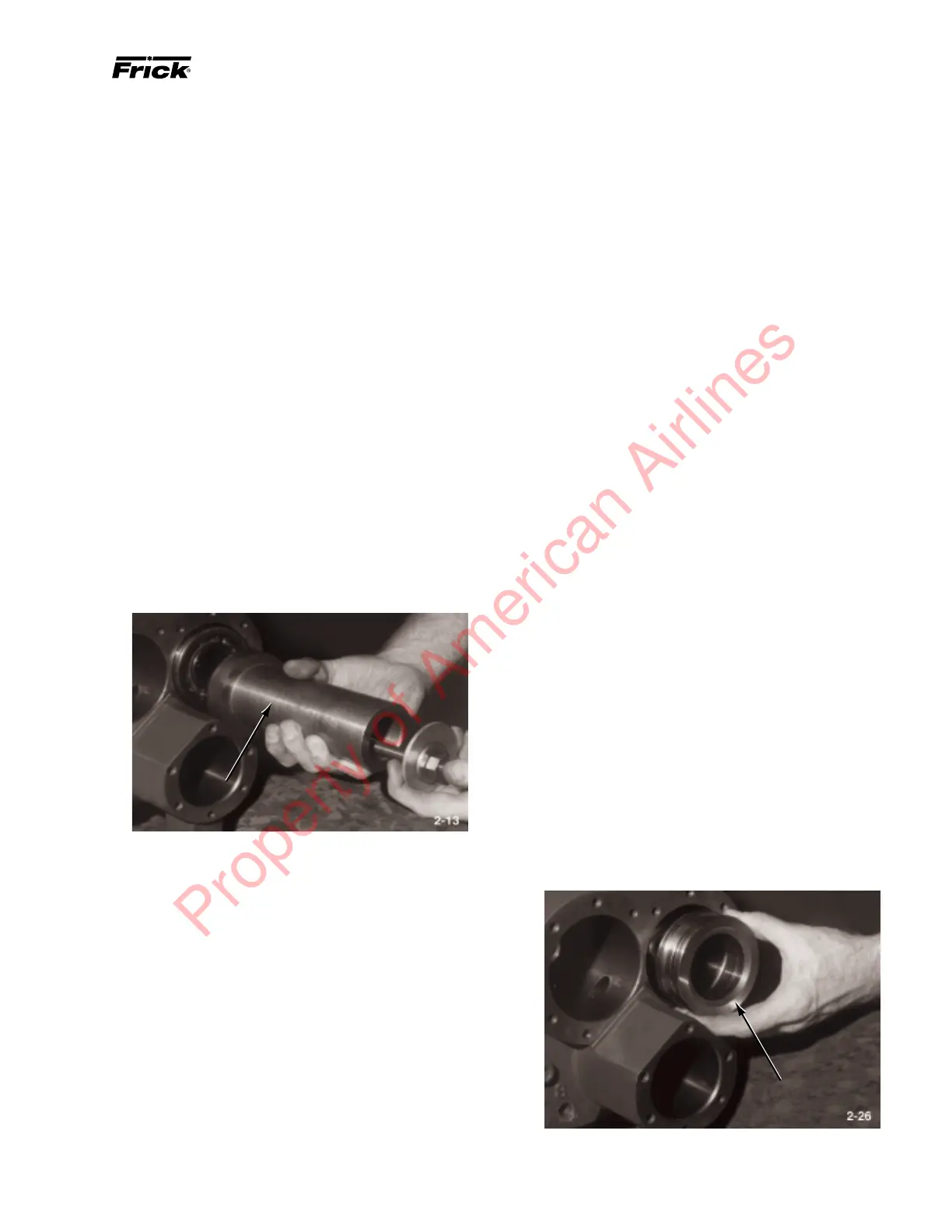

23. Place new o-rings (27 and 29) on balance piston (33) and

new o-ring (29) on piston sleeve (30). Assemble balance

piston, wave spring (31), and balance piston sleeve and install

assembly over male rotor shaft. Balance piston faces out.

BALANCE PISTON

14. If same rotor pair is to be reinstalled, place original shims

(removed in steps 14 and 15 of paragraph 1.4.1) over male and

female rotors and against roller bearings. If a new rotor pair is

being installed, use shims that were calculated in step 7, this

section. See Figure 1-6 for shim placement and correct orien-

tation of bearings.

NOTE: Use 12mm T-wrench threaded into opposite end

of rotor to prevent rotor from turning while using Dis-

charge Ball Bearing Installation Tool.

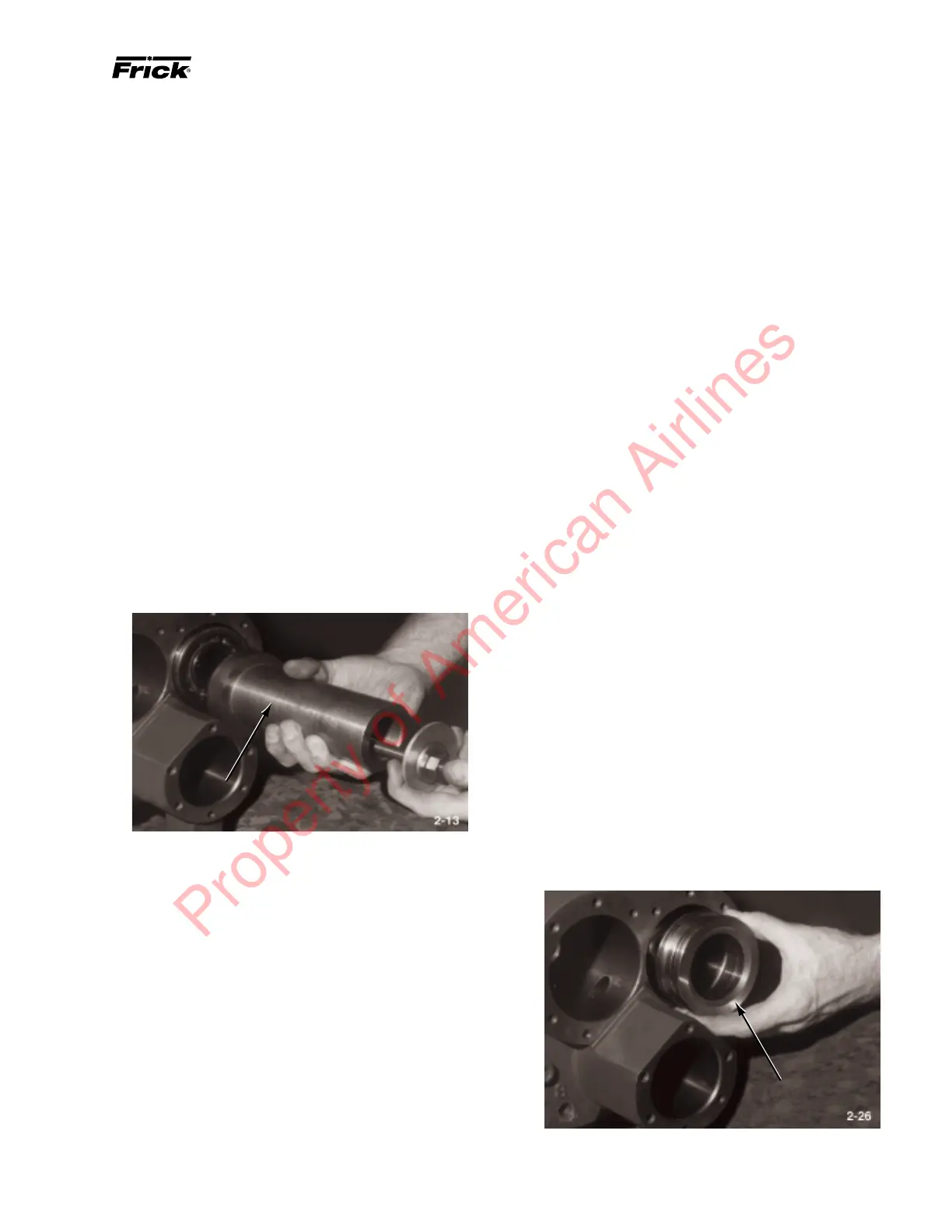

15. Using Discharge Ball Bearing Installation Tool, install

two angle contact ball bearings (26), one at a time, on female

rotor shaft. Ensure that bearings are installed with closed side

of inner races back-to-back (identification markings on bear-

ings facing away from each other). See Figure 1-6 for correct

orientation of bearings. (A .002-inch shim is required between

inner races when wave spring is used on bore cover.)

NOTE: Use 12mm T-wrench threaded into opposite end

of rotor to prevent rotor from turning while using Dis-

charge Ball Bearing Installation Tool.

16. Using Discharge Ball Bearing Installation Tool, install two

angle contact ball bearings, one at a time, on male rotor shaft.

Ensure that bearings are installed with closed side of inner races

facing outboard (identification markings on bearings facing

inboard). See Figure 1-6 for correct orientation of bearings.

DICHARGE BALL BEARING

INSTALLATION TOOL

17. Install lockwasher (35) and locknut (36) on female rotor

shaft; tighten locknut with spanner wrench to 150 ft.-lb. (204

Nm)on the 120mm and 90 ft.-lb. (122 Nm) on the 95mm. DO

NOT bend tab.

18. Install bearing spacer (32) and Spacer Tool (1

15

/16 OD x

1

9

/16 ID x

7

/8-inch thick – used to take place of last bearing)

on male rotor shaft.

19. Install lockwasher (35) and locknut (36) on male rotor

shaft; tighten locknut with spanner wrench to 150 ft.-lb. (204

Nm)on the 120mm and 90 ft.-lb. (122 Nm) on the 95mm.. DO

NOT bend tab.

20. With Air Cylinder Tool still attached to drive end of

compressor, take same measurements as in step 13, this

section. Measured end clearances should be .0015 to .003-

inch. Record measured end clearances on Table 1.1. If clear-

ance is less than .0015-inch, install shims on rotor between

Property of American Airlines

Loading...

Loading...