S70-101SM

Page 5

Frick XJS and XJF Rotary Screw Compressor

Service Manual

GENERAL SAFETY PRACTICES (CONTD)

1. If you are not familiar with this particular Frick compres-

sor, take time to read the operator’s manual (IOM) before

attempting to run the unit for any purpose.

2. INSPECT COMPRESSOR VISUALLY before start-up.

Tighten/replace any loose or missing bolts, nuts, etc. Repair

any leaks; replace any damaged hoses, lines, and/or fittings;

repair/replace any damaged electrical wiring and/or compo-

nents.

3. USE CAUTION PRIOR TO DISASSEMBLY, as com-

pressor may still be pressurized. Evacuate compressor in

accordance with S70-101 IOM and applicable Federal, State,

and local ordinances, prior to begining any disassembly.

4. DO NOT make adjustments while the unit is operating,

unless required for service or maintenance checks.

5. DO NOT operate a damaged compressor. Always com-

plete all repairs before running unit.

6. STAY ALERT at all times. Watch what you are doing at

all times. Be aware of all persons in the immediate vicinity of

operating equipment. Allow only authorized personnel in the area.

7. NEVER operate compressor if you are taking medication

that causes blurred vision, dizziness, drowsiness, or slowed

reflexes.

8. DO NOT operate compressor if excessive vibration oc-

curs. Immediately shut down unit and complete all necessary

repairs and required checks before attempting to restart.

9. DO NOT operate compressor exhibiting excessive pres-

sure and/or temperature changes. Immediately shut down unit

and complete all necessary repairs and functional checks

before attempting to restart.

10. NEVER alter compressor from original design. Only those

alterations approved by Frick Company and/or performed by

authorized Frick service personnel are permitted.

11. KEEP COMPRESSOR CLEAN, free of debris, and

properly lubricated. A clean, properly lubricated unit will

perform more efficiently and operate trouble-free much longer.

REMEMBER: Any piece of equipment is only as safe

as those who use and maintain it.

1.0 COMPRESSOR TEARDOWN.

The procedures presented in this manual assume that all

maintenance wil be performed by qualified, Frick-trained

service personnel equipped with all special tools and test

equipment necessary to properly teardown and rebuild Model

XJS and XJF 95/120 compressors.

1.0.1 COMPRESSOR – DISASSEMBLY. Compressor disas-

sembly shall be accomplished in the following order:

1. Shaft Seal – Removal (Refer to paragraph 1.1.2).

2. Jackshaft and Gears – Removal (Refer to paragraph

1.2.1).

3. Slide Valve and Slide Stop – Removal (Refer to para-

graph 1.3.1).

4. Rotors and Bearings – Removal (Refer to paragraph

1.4.1).

5. Compressor Suction Strainer – Removal (Refer to paragraph

1.5.1).

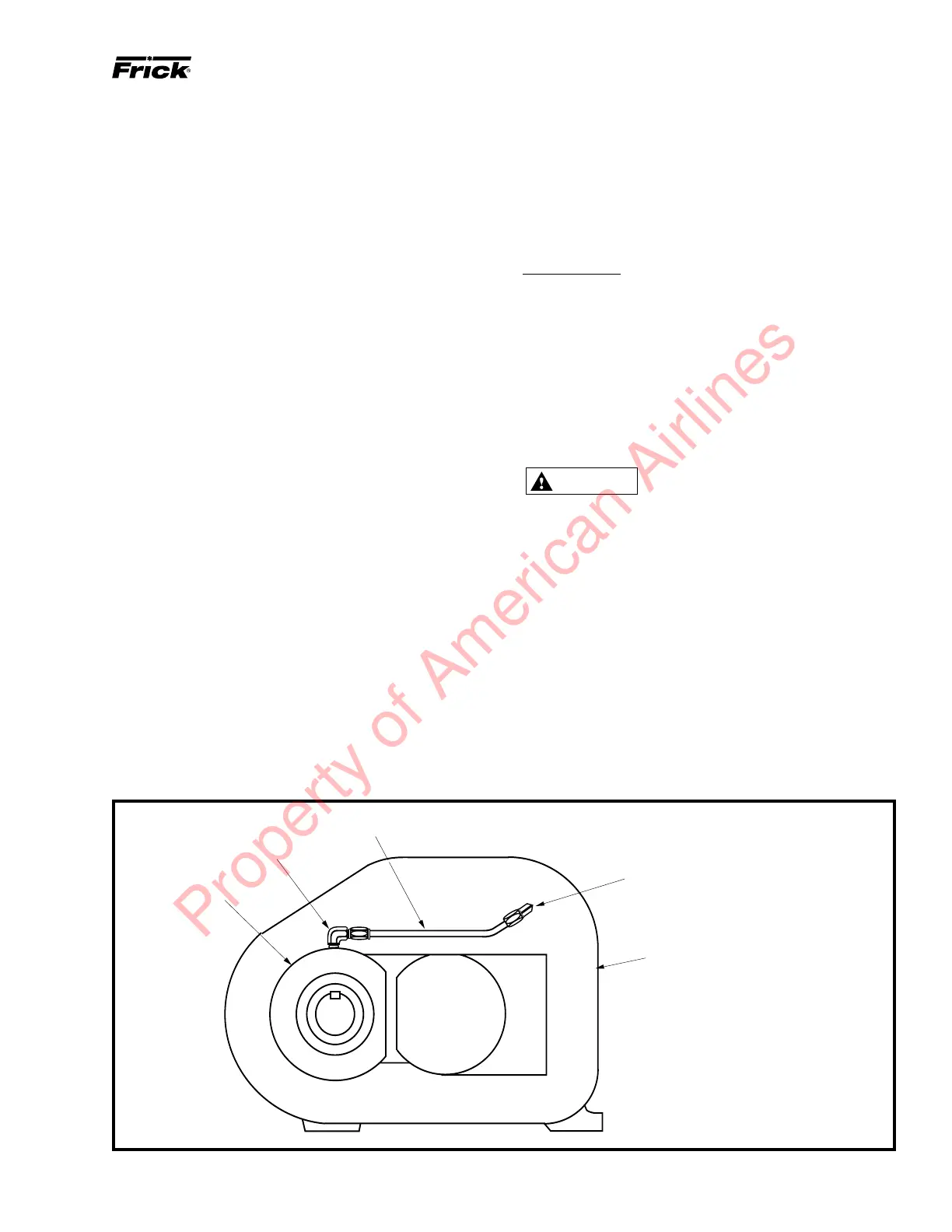

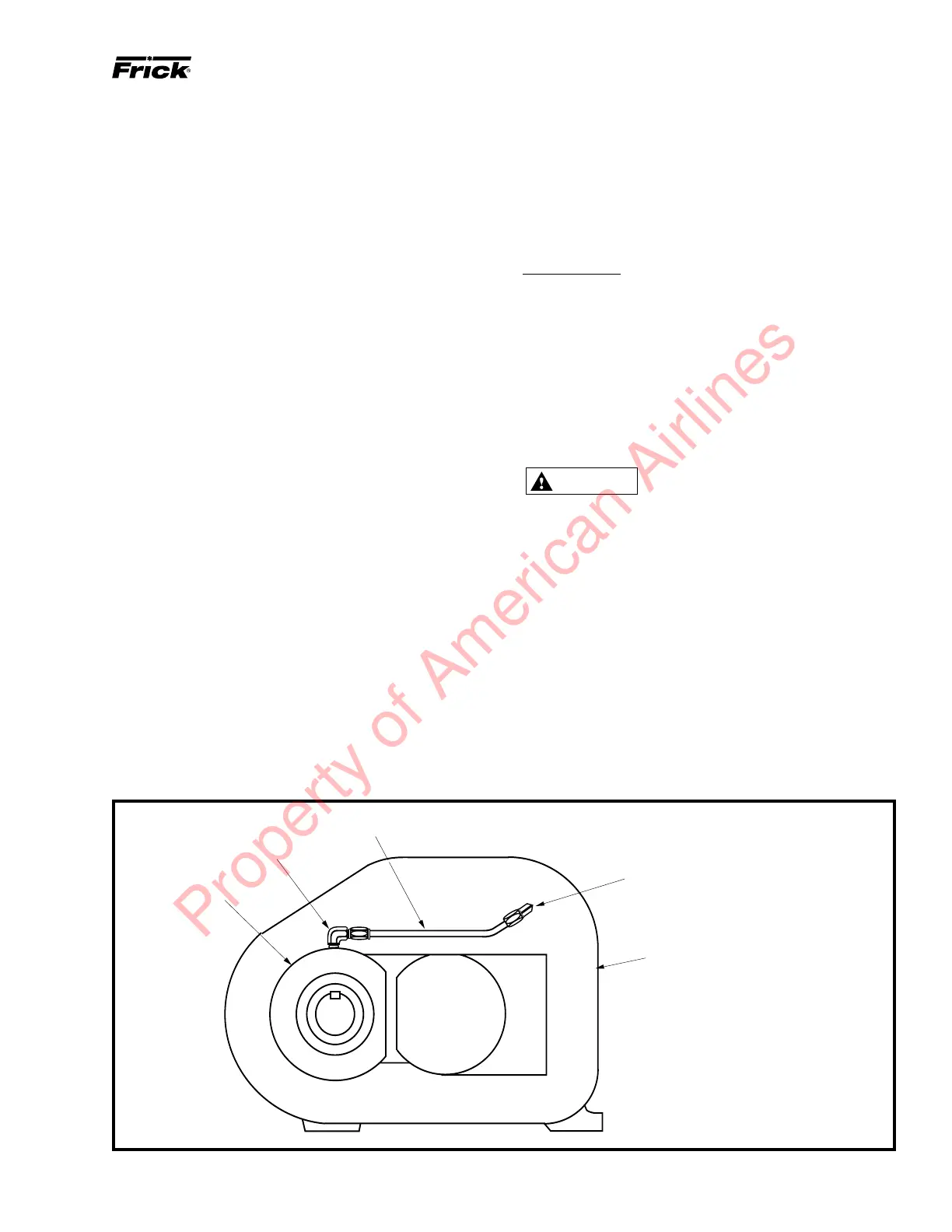

Figure 1-1. Compressor Gear Cover – End View.

1

2

3

2

4

1. Seal Housing

2. Elbow

3. Oil Supply Line

4. Gear Cover

XJS and XJF 95 weigh 500 lb.(227

kg);XJS and XJF 120 weigh 750

lb.(340 kg). Ensure that rigging is

properly attached and secure before

lifting compressor.

WARNING

Property of American Airlines

Loading...

Loading...