Page 23

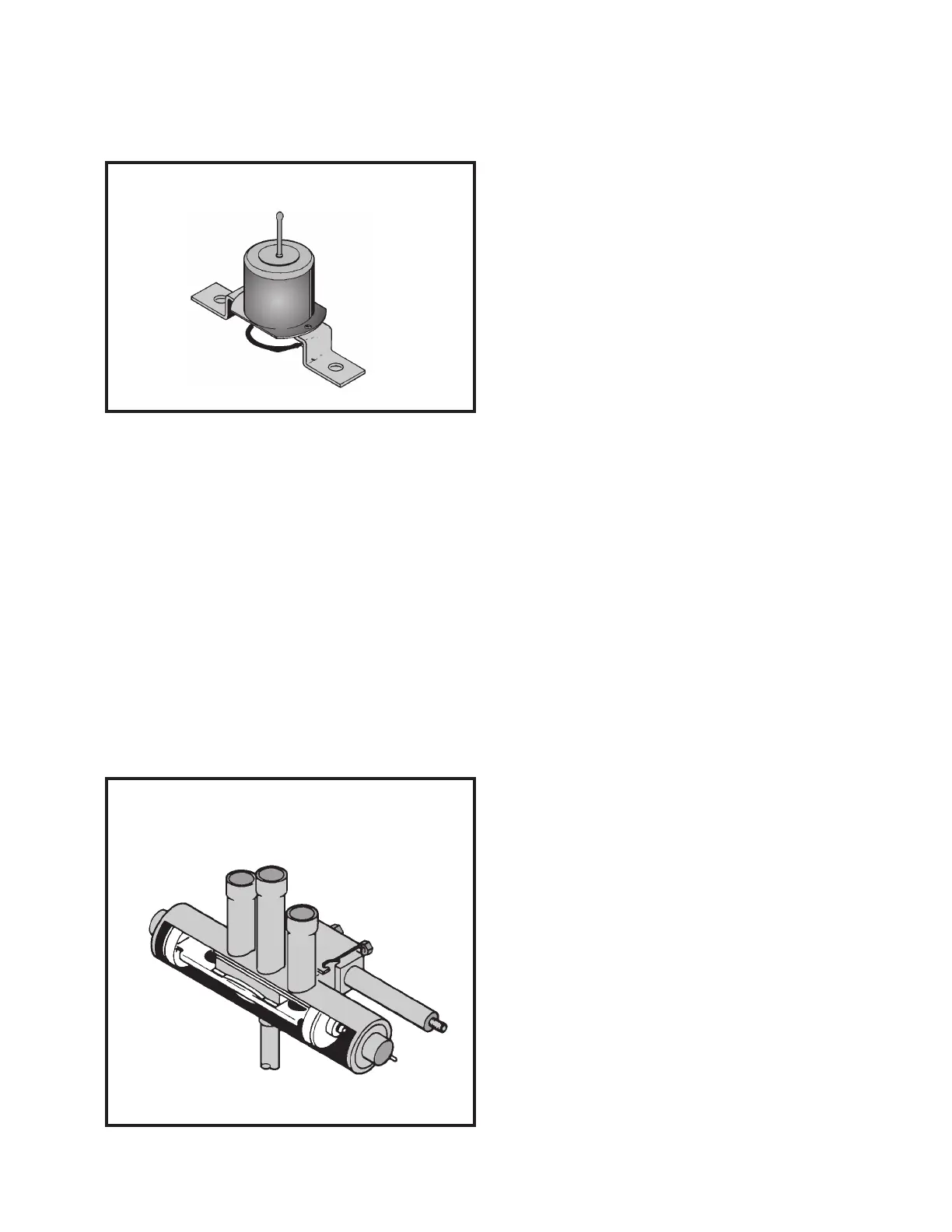

This valve is temperature sensitive and will open when

the outside temperature reaches 40°F. The valve will close

gradually as the temperature rises above 40°F to fully

close at 60°F.

Figure 16: DRAIN PAN VALVE

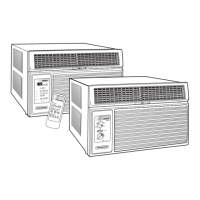

REVERSING VALVE

(Heat Pump Model Only)

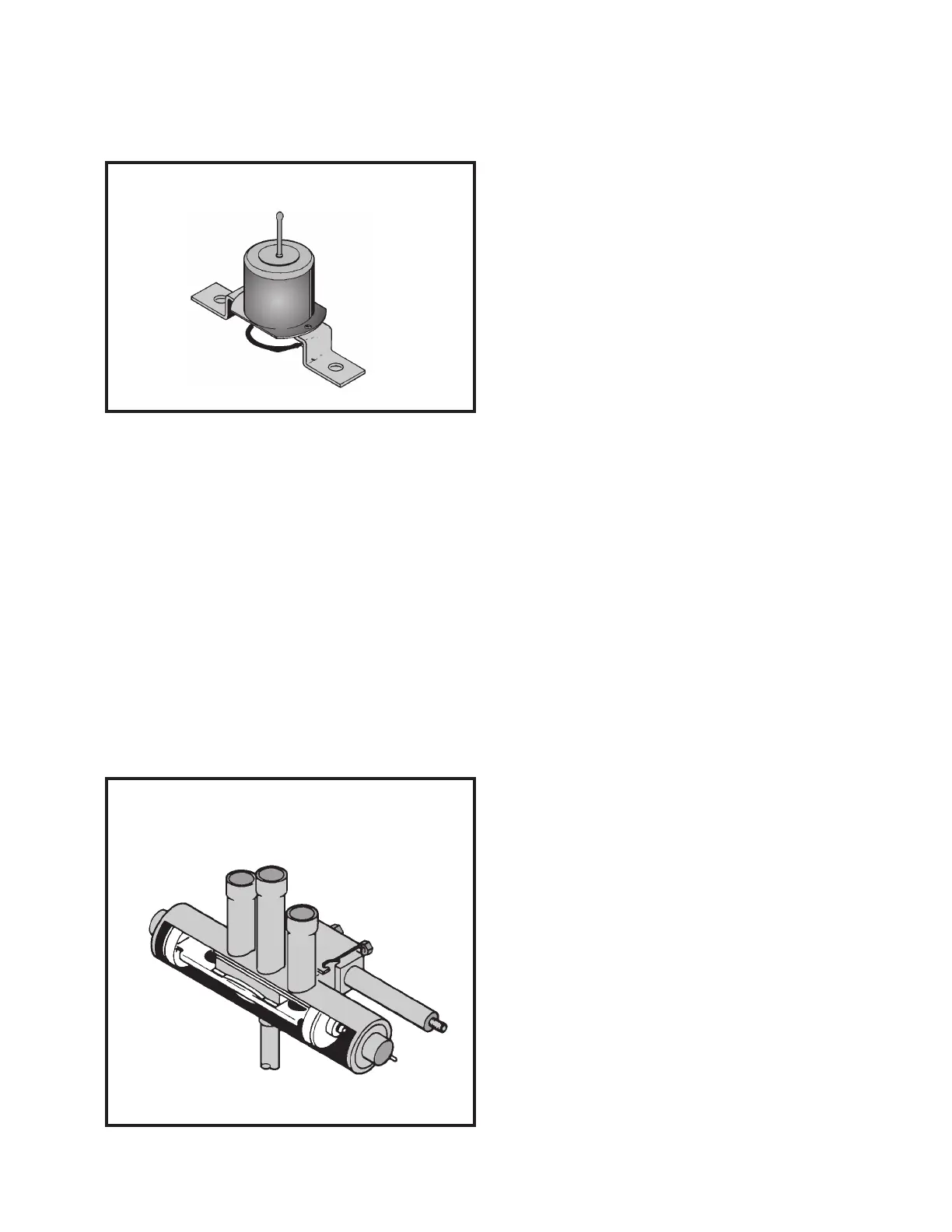

A reversing valve is used to change the refrigerant flow

within the system to permit heating or cooling (see Figure

17.)

The reversing valve consists of a main valve body which

houses the slide and piston, plus a pivot valve which is

activated by a solenoid.

There are three tubes connected to one side of the main

valve body and one tube on the opposite side. The single

tube is connected to the compressor discharge line. The

center tube on the opposite side is the common suction

line to the compressor. The outside tubes are connected

to the indoor and outdoor coils.

Figure 17: REVERSING VALVE

The pilot valve is responsible for directing the refrigerant

flow to the indoor or outdoor coil. There are three small

tubes connected to the pilot valve body. The center pilot

tube is the common pilot tube and is connected to the

center suction line. The outside tubes are connected to

each end of the main valve body. The pilot valve consists

of a needle valve and spring. When the solenoid is de-

energized, the spring tension closes one pilot port while

the others remain open. When the solenoid is energized,

the opposite end is closed. The piston in the main valve

is pressure operated and will always travel in the direction

of the open pilot tube port which provides a path to the

center tube. Pressure which will increase in the opposite

end of the valve will escape through a bleed port located

in each piston. When de-energized, the valve will be in

the cooling position.

TESTING REVERSING VALVE

Occasionally, the reversing valve may stick in the heating

or cooling position or in the mid-position.

When stuck in the mid-position, part of the discharge

gas from the compressor is directed back to the suction

side, resulting in excessively high suction pressure.

Check the operation of the valve by starting the system

and switching the operation from "cooling" to "heating"

and then back to "cooling". Do not hammer on the valve.

If valve fails to change its position, test the voltage to

the valve coil while the system is in the heating cycle. If

voltage to coil is satisfactory, replace reversing valve.

Should the valve fail to shift from cooling to heating,

block the air flow through the indoor coil and allow

discharge pressure to build in the system. Then switch

the system from cooling to heating.

If valve is stuck in the heating position, block the air

flow through the indoor coil and allow discharge pressure

to build in the system. Then switch the system from

heating to cooling.

Should the valve fail to shift in either position after

increasing the discharge pressure, replace the valve.

NOTE: When brazing a reverse valve into the system,

it is of extreme importance that the temperature

of the valve does not exceed 250°F at any time.

Wrap the reversing valve with a large rag

saturated with water. "Re-wet" the rag and

thoroughly cool the valve after brazing operation

of the four joints involved.

The wet rag around the reversing valve will

Figure 17: REVERSING VALVE

Loading...

Loading...