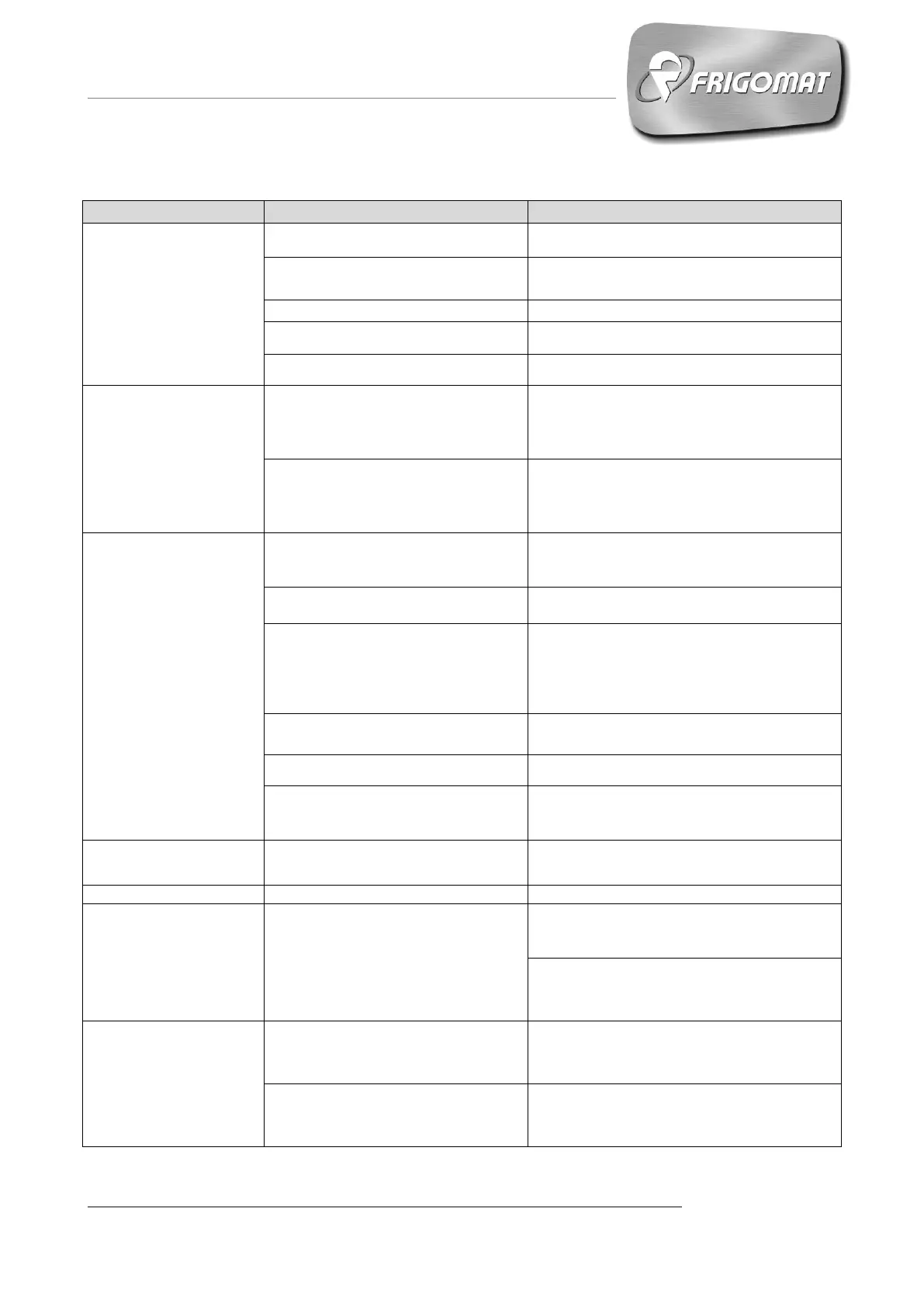

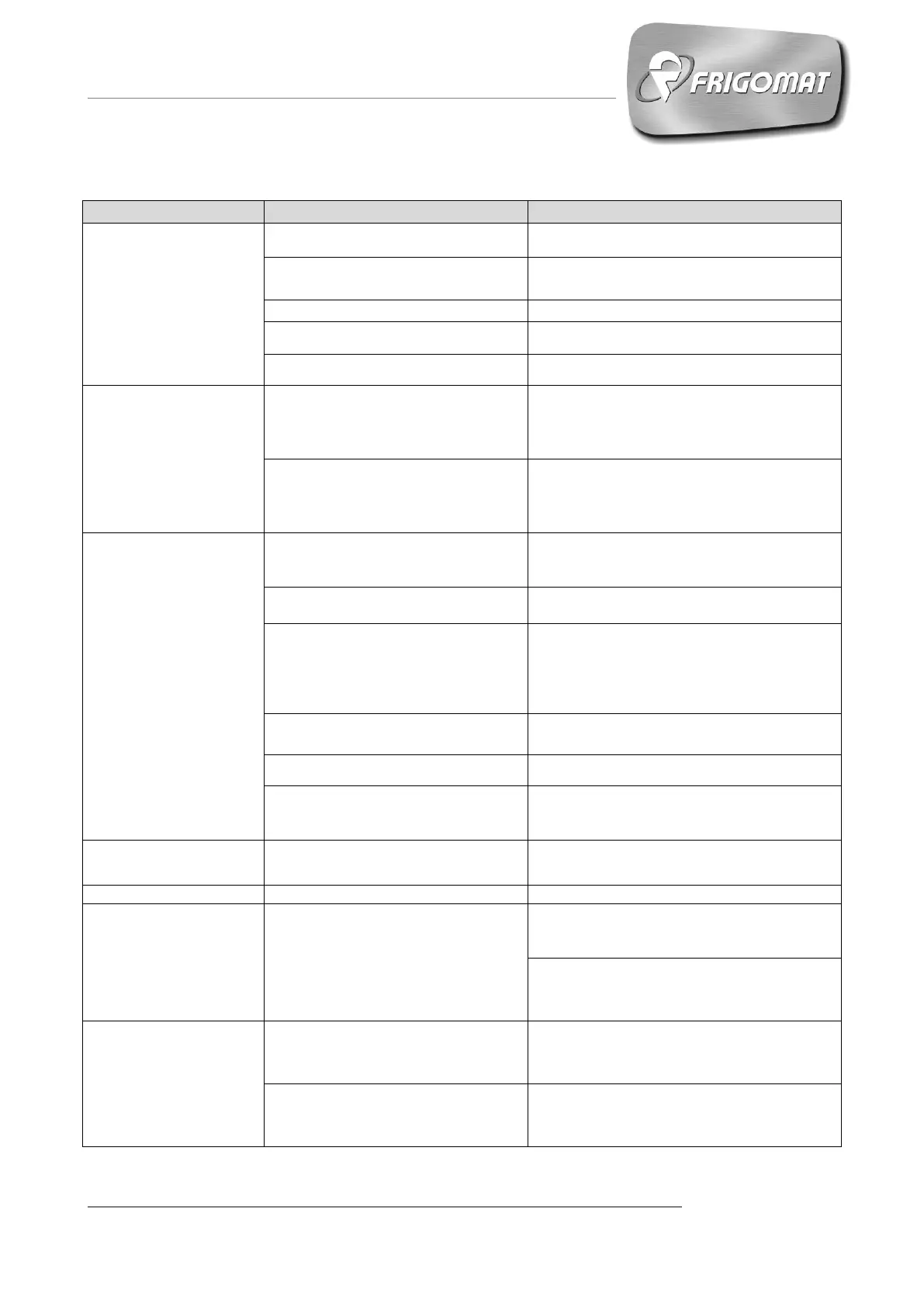

8 TROUBLESHOOTING

The machine does not

start

(ON/OFF button active

with green LED).

Lid raised or not assembled.

Lower the lid and/or check that it is

assembled correctly.

Assemble the door on the machine.

Turn the selector to position 1.

The compressor

functions intermittently

from the first batch

freezing phases.

Air-cooled machines: air condenser

dirty or fan faulty.

Clean the condenser with a brush and

make sure the fan works properly.

Water-cooled machines: no

condensation water.

Make sure there is water in the water

system to which the machine is connected.

Check the cocks.

The batch freezing times

lengthen and/or the ice-

cream appears wet.

Check that there is at least 30 cm (mod. air)

between the rear panel of the machine and

the wall or other obstacles.

Check that the room temperature does not

exceed 32°C.

High liquid mixture temperature.

Maximum machine production is obtained

with a liquid mixture at 4°C. Using mixtures

at higher temperatures means that batch

freezing times are lengthened: this is

normal and does not constitute an anomaly.

Check wear and replace them if necessary.

Refrigeration system anomaly.

Unbalanced mixture or incorrect

amount introduced.

Check that the amount of mixture

introduced is correct and that it is balanced

properly.

Insufficient batch freezing time.

Select a longer time on the timer.

Excessive batch freezing time.

Select a shorter time on the timer.

The machine becomes

noisy during batch

freezing.

Presence of ice on the cylinder wall.

The ice-cream is ready to be extracted.

Check that the quantity introduced into the

cylinder is not lower than the minimum

allowed.

The machine does not

extract the ice-cream.

The selector switch is not on

position 2.

Turn the selector to position 2.

The selector switch is on position 2

but the beater turns in the opposite

direction.

Invert the phases in the plug.

(Contact the technician).

Loading...

Loading...