EN

FRIGOMAT GX4Kompact, GX6, GX8 M04.42026 R.2019.05.30 3

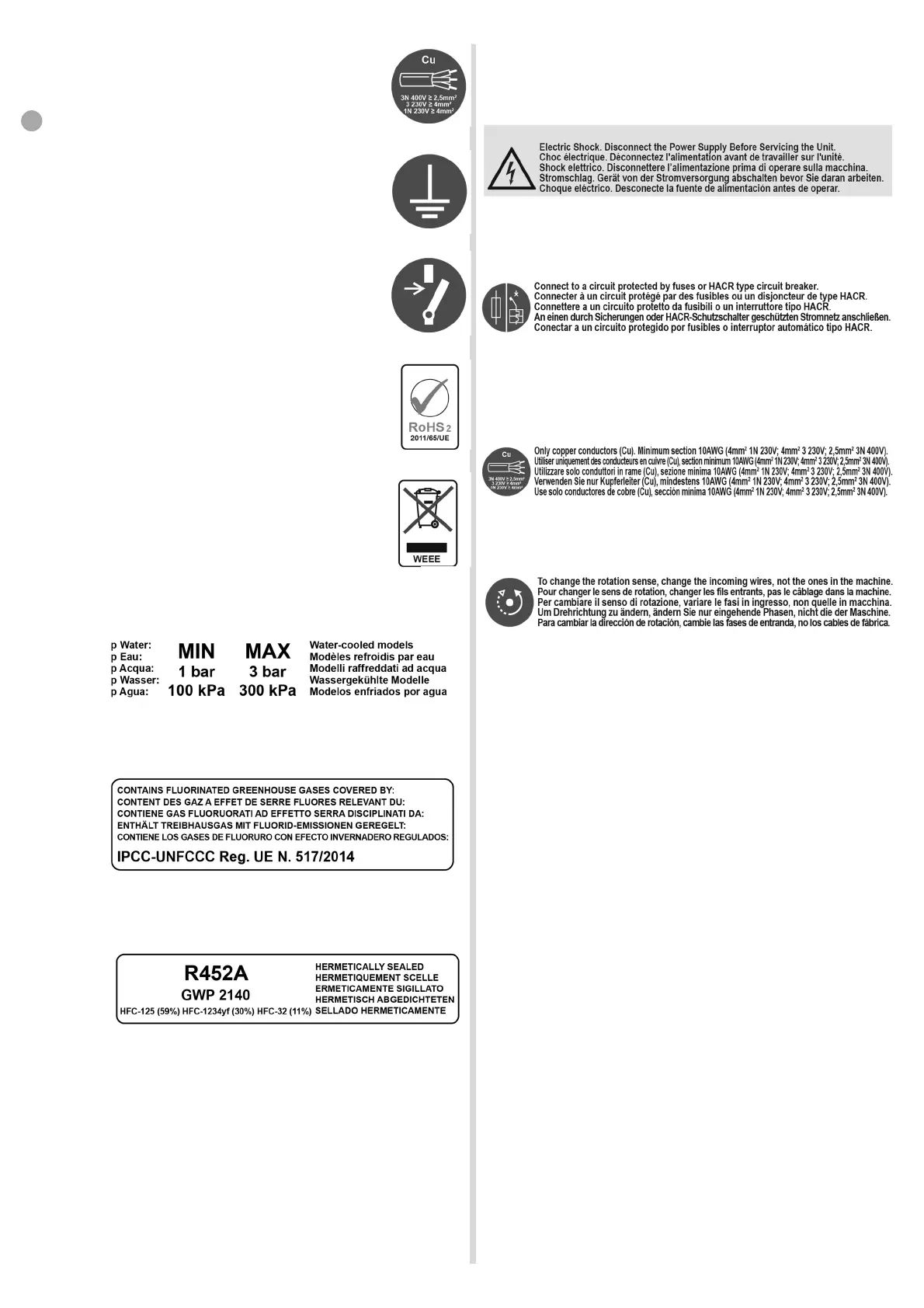

Label: use of power cord with the characteristics indica-

ted (fig.I/09).

The label indicates which features the power cord should

have if it is replaced.

Label: ground connection (fig.I/10)

This equipment must be properly grounded! Failure to do so

can result in severe personal injury from electrical shock!

Label: obligation to disconnect the machine before car-

rying out maintenance / repairs (fig.I/11)

Disconnect the power supply before servicing the machine.

Label: Rohs2 compliant machine (fig.I/12)

Label: RAEE compliant machine (fig.I/13)

For decommissioning, comply with the standards in force in

the country where it is used.

Label: allowed water pressure values (water models) (fig.I/14)

Report the minimum and maximum permissible pressure values

Label: contains regulated gases (fig.I/15)

Gas specification contained in the hermetically sealed refrigerant circuit.

Label: specific refrigerant gas (fig.I/16)

Use only the gas indicated on the label.

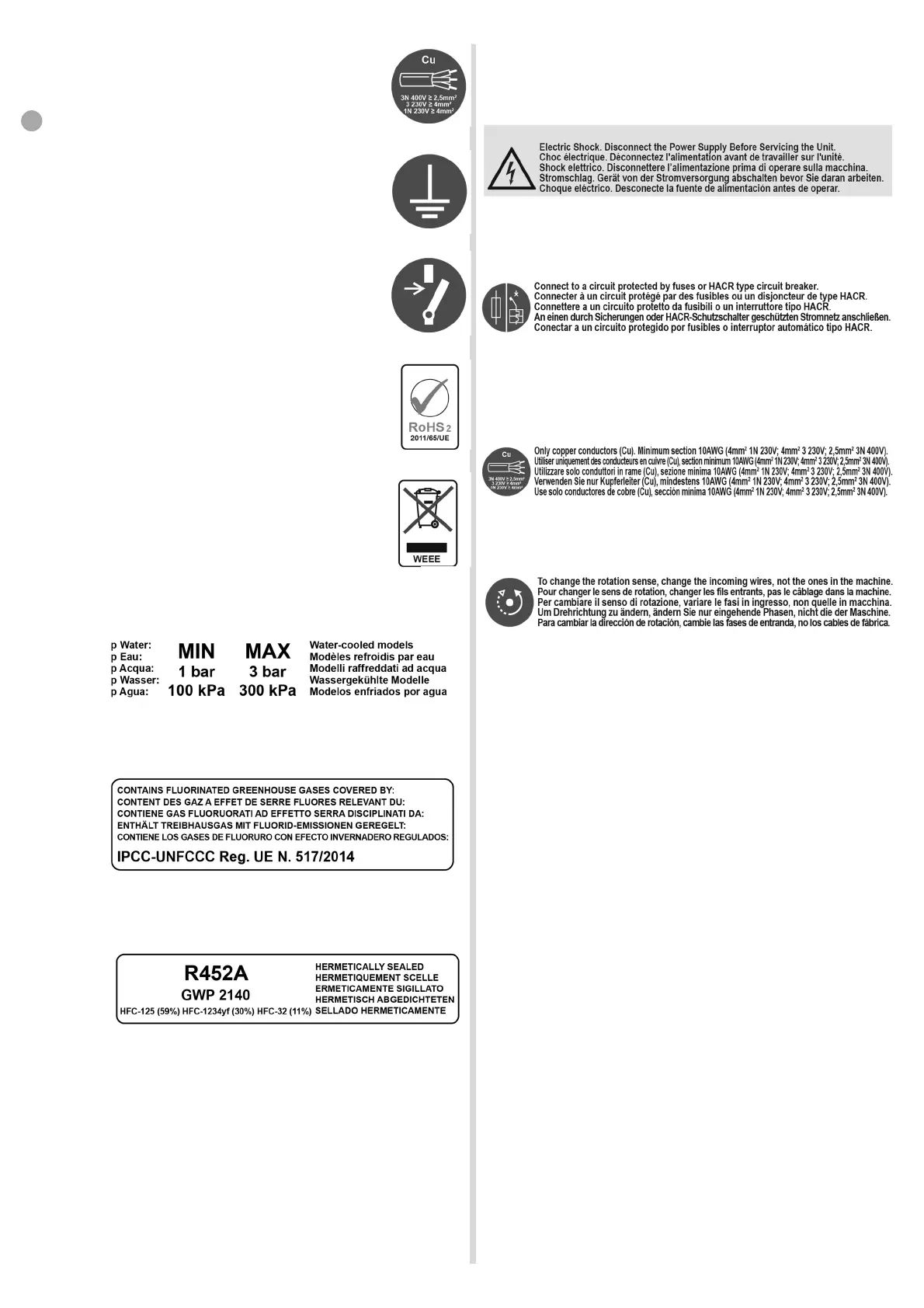

4.2 Electrical Box Warning Label

Label: danger high voltage inside (fig.I/17)

High voltage inside, danger of electrocution. Disconnect the Power Supply

Before Servicing the Unit.

Label: electrical protection insertion obligation (fig.I/18)

Connect to a circuit protected by fuses or HACR type circuit breaker.

Label: use of power cord with the characteristics indicated (fig.I/19)

The label indicates which features the power cord should have if it is repla-

ced.

Label: correct rotation direction (fig.I/20)

The label indicates how to reverse the direction of rotation in three-phase

machines.

5 SAFETY DEVICES

The machine is equipped with the following safety devices:

Shearing-prevention safety device

Implemented by means of a safety circuit compliant with the European direc-

tive, it intervenes when the cover is opened, temporarily switching the ma-

chine to STOP mode.

Beater motor overheating safety device

Implemented by means of automatic reset circuit breaker-relays; they pro-

tect the machine beater motor operation from overloads.

Hermetic compressor motor overheating safety device

Implemented by means of automatic reset thermal-ammetric sensors; they

protect the machine compressor motor operation from overloads. The pro-

tection device intervention determines the temporary stop of the compressor

motor only.

Chiller circuit over-pressure safety device

Implemented by approved automatic reset safety pressure switches; they

protect the integrity of the chiller circuit from overpressure.

Protection against short circuit of auxiliary utilities:

Implemented by fuses which intervene on the auxiliary power supply in the

event of short-circuits.

Safety circuit SELV

The keyboards are powered by low voltage safety

fig.I/09

fig.I/17

fig.I/10

fig.I/11

fig.I/12

fig.I/13

fig.I/14

fig.I/15

fig.I/16

fig.I/18

fig.I/19

fig.I/20

Loading...

Loading...