EN

FRIGOMAT GX4Kompact, GX6, GX8 M04.42026 R.2019.05.30 5

4.2 Electrical connections

Each machine must be connected to a power line dedicated to sanitary

power, a standard and in perfect working order.

Check the exact correspondence between the voltage and power of the

mains compared to the values carried on the data plate applied on the side

of the panel.

Connect the machine to the electrical power supply system. Install a omni-

polar master switch upstream the appliance with minimum contact opening

of 3 mm of adequate power, with a fuse and circuit breaker protective sy-

stem. Use an approved interlocking plug to allow only the

The cable must be well laid, without being rolled-up or overlapped. It must

not be exposed to blows or tampering. It must not be in the vicinity of liquids

or water and heat sources. It must not be damaged in any way. If so, before

connecting the machine to the mains, have it replaced by qualified person-

nel with another having suitable section and type H07RN-F.

For safety purposes, make sure the earthing system to which the

machine plug is connected is compliant with standards and per-

fectly efficient. Failure to comply may result in electrocution.

If needed, carry out an equipotential bonding, using the screw

placed on the rear of the machine below the frame and marked

with the symbol shown in figure (fig.II/2).

The three-phase machines are powered with three-phase + neu-

tral line: pay maximum attention to never connecting the phase

lines with the neutral. The manufacturer declines all responsibili-

ty for damage to the machine resulting from this failure.

4.3 Refrigerant

This machine contains fluorinated greenhouse gases (F-Gas) to provide

refrigeration using a hermetically sealed circuit or within foam insulation.

This machine's type of gas, quantity, Global Warming Potential (GWP), and

CO

2

tonnes equivalent information is recorded on the unit's data-label.

The refrigerant used is generally considered non-toxic and non-flammable.

However any gas under pressure is potentially hazardous and must be han-

dled with caution.

Refrigerant liquid sprayed onto the skin may cause serious damage to tis-

sue. Keep eyes and skin protected.

If refrigerant burns should occur, flush the area immediately with cold water.

If burns are severe, apply ice packs and contact a physician immediately.

5 OPERATING CHECKS

These operations are reserved exclusively for authorised from the manifac-

turer and qualified personnel.

5.1 Beater motor rotation direction

The following checks must be carried out during the first commissioning and

whenever the plug is connected to a new socket.

Power the machine, press the AGITATION/P key and control that the beater

rotates anticlockwise. If this is not the case, exchange the phases in the

plug. To connect the phases properly cut the power and invert the two pha-

se wires in the plug.

Use of the machine with incorrect beater motor rotation se-

riously damages general performance and causes early wear of

the scrapers.

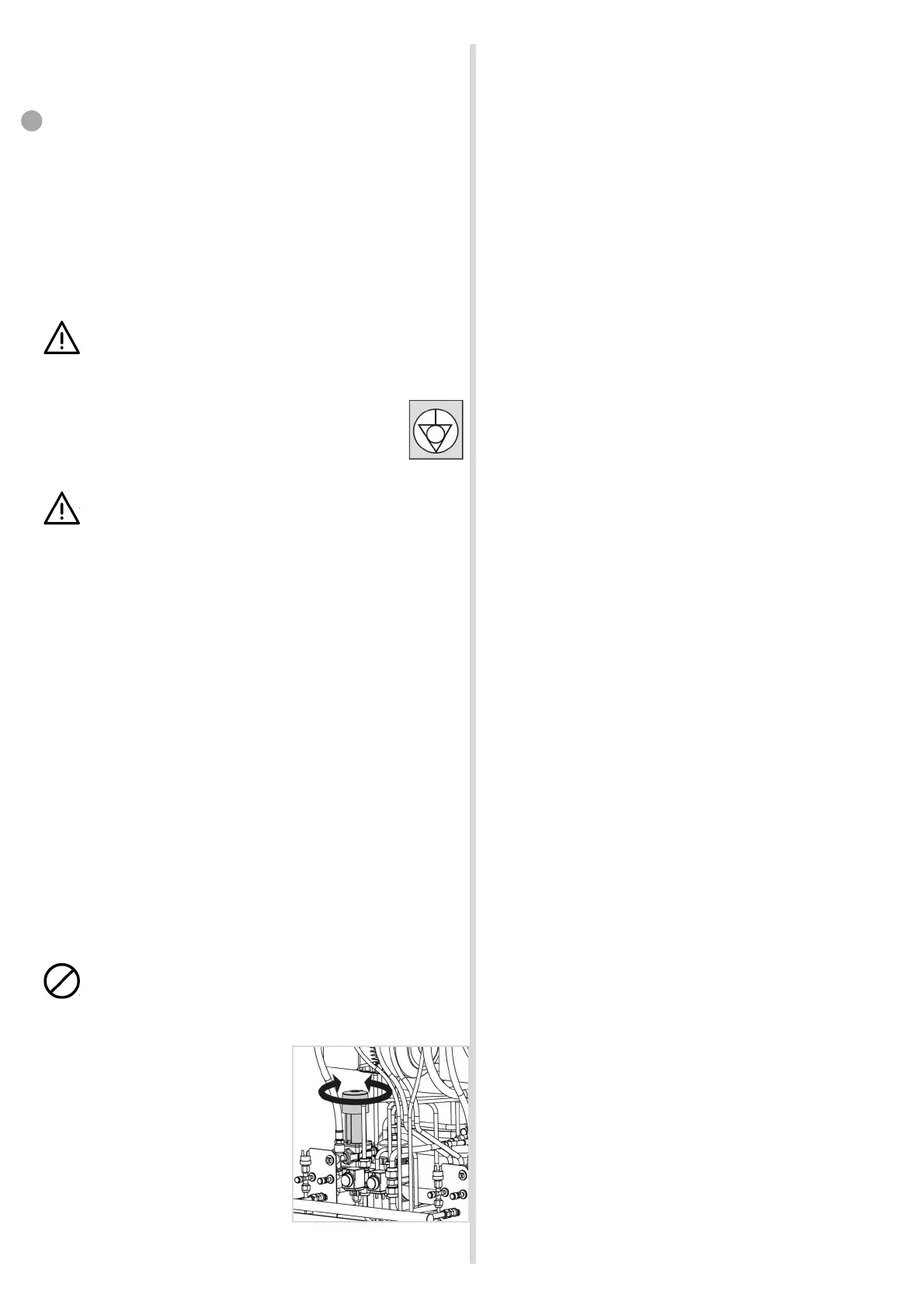

5.2 Condensation pressure.

The following verification must be carried out

during the first commissioning and whenever

the loading and unloading pipes are con-

nected to a different water line.

With the machine in production mode, after a

few seconds condensation water must come

out of the drain pipe at a temperature of

about 32 °C - 35 °C (90 °F - 95 °F)

If this is not the case, the pressure switch

valve shown in the figure must be adjusted

(fig.II/03).

fig.II/02

fig.II/03

Loading...

Loading...