7

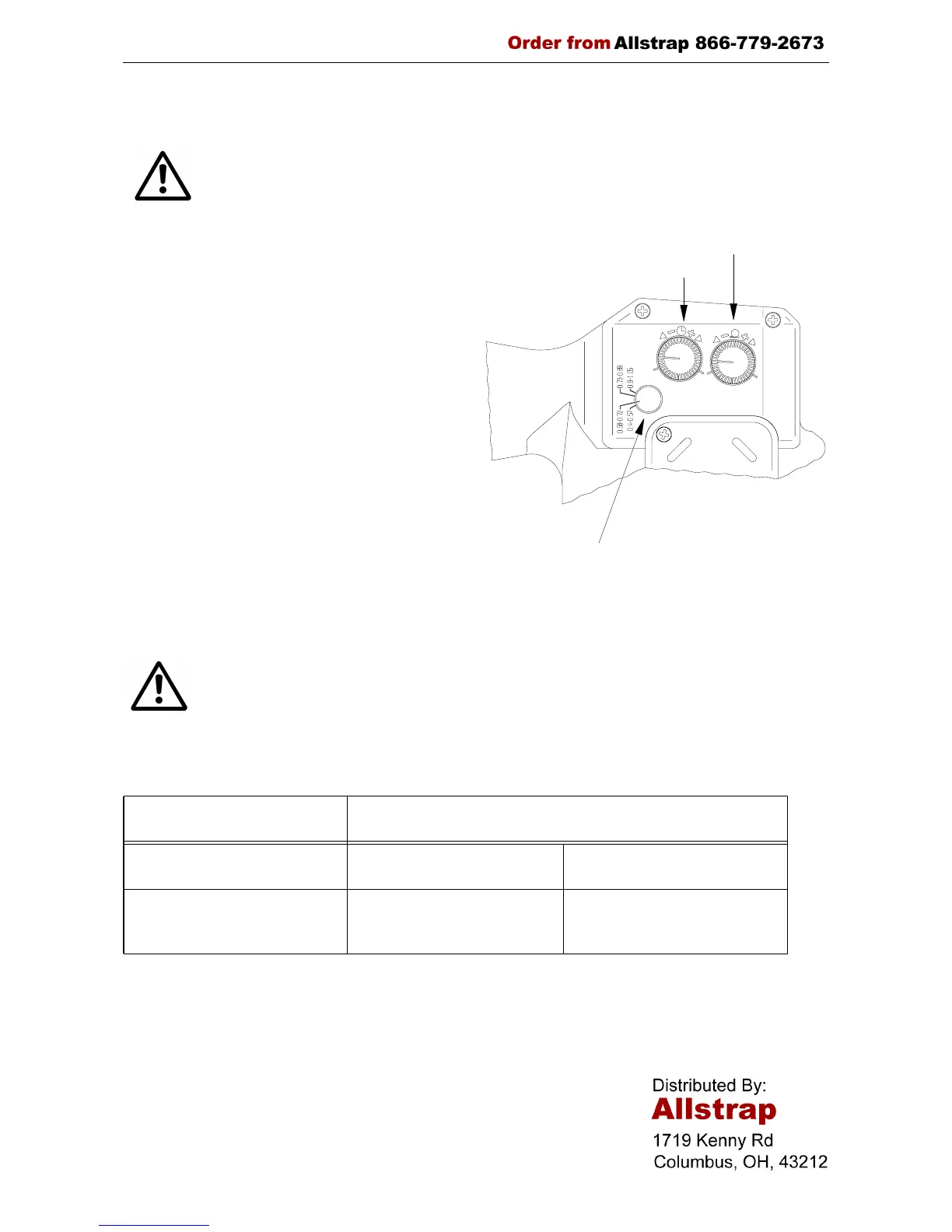

5.2 Adjustments

5.2.1 Preselecting of the strap tension

Do not adjust the tensioning force too high.

If the tensioning force is higher than the tensioning strength of the strap,

the strap will tear while the tensioning.

The tensioning force can be steadily adjusted

(400 - 2000N / 90 - 450 lbs) by means of the right

adjusting knob.

Turning clockwise increases,

adjusting counterclockwise decreases the

tensioning force.

5.2.2 Adjusting the welding time

Depending on the size and quality of the strap,

different welding times are required.

The welding time can be adjusted at the left

adjusting knob.

Turning clockwise increases,

turning counterclockwise decreases the welding

time.

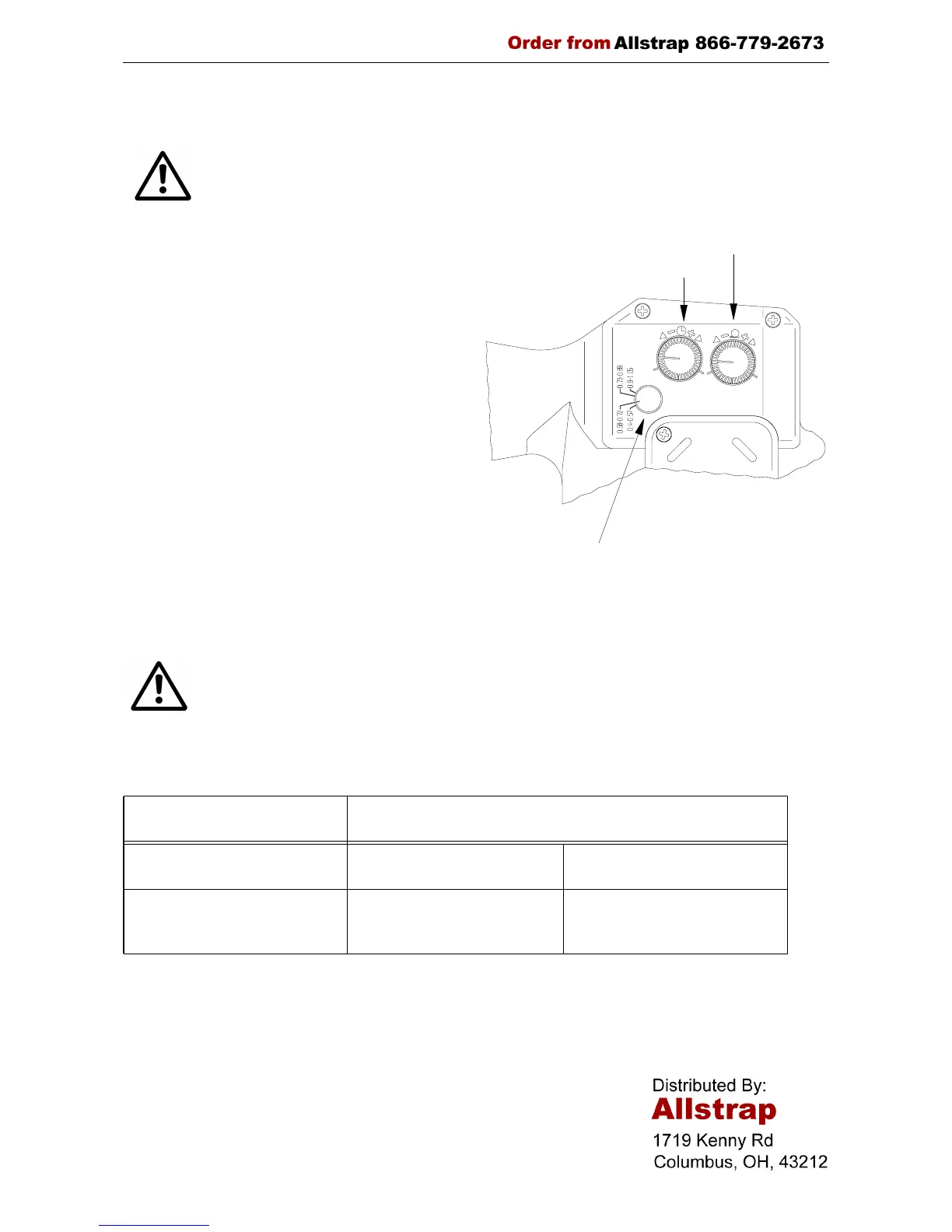

5.2.3 Adjusting the welding pressure

In order to assure optimal welding, the pressure of the welding gripper to the straps to be welded must be

within a certain range. Depending on the thickness of the strap, this pressure is adjusted by means of the

adjusting pin.

When adjusting the welding pressure, the lever must be latched into its start position.

Disregarding this regulation will cause considerable trouble.

The range of thickness of the strap must be adjusted according to the strap thickness admitted for the tool

(see chart of types) and the thickness of the strap to be processed.

Adjustment:

The lever is latched and in start position!

Pull out the adjusting pin of the tool,

turn it into the desired position (observe the marking on the housing),

release the adjusting pin (the adjusting pin must latch without assistance).

Model Welding pressure,

Possible adjustments

Strap thickness 0.40 - 0.64 mm

(.016 - .025")

0.40 - 0.57 mm (.016 - .022")

0.58 - 0.72 mm (.023 - .028")

Strap thickness 0.65 - 1.05 mm

(.026 - .041")

0.58 - 0.72 mm (.023 - .028")

0.73 - 0.89 mm (.029 - .035")

0.90 - 1.05 mm (.035 - .041")

Adjusting knob tensioning force

Adjusting knob welding time

Adjusting pin

welding pressure

Loading...

Loading...