88

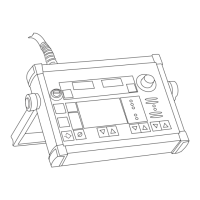

Description of

US control panel

(continued)

(4) Process button(s) ... for selecting the welding process

- MIG/MAG pulsed-arc welding

- MIG/MAG standard welding

- Manual process

- Job mode (Job)

- TIG welding with touch-down ignition

- Rod electrode (MMA) welding

(5) Mode button(s) ... for selecting the operating mode

- 2-step mode

- 4-step mode

- Aluminium welding start-up

- Spot-welding mode

- Mode

(6) Material button(s) ... for selecting which filler metal and shielding gas you want to

use. Parameters SP1 and SP2 are reserved for additional materials.

(7) Wire-diameter button ... for selecting the diameter of wire that you want to use.

Parameter SP is reserved for additional wire diameters.

(8) Welding current parameter ... for selecting the welding amperage. Before the start

of welding, the machine automatically displays a guideline value derived from the

programmed parameters. During welding, the actual value is displayed.

(9) Welding voltage parameter ... for selecting the welding voltage. Before the start of

welding, the machine automatically displays a guideline value derived from the

programmed parameters. During welding, the actual value is displayed.

Important! The power source has a pulsating open-circuit voltage. Where the “Rod

electrode (MMA) welding” process has been selected, the display indicates an

average welding-voltage value of 40 V before the start of welding (open circuit).

For welding start-up and the main welding operation itself, however, a welding

voltage of max. 50 V (TPS 2700) or 70 V (TS/TPS 4000/5000) is available. Opti-

mum ignition properties are ensured.

(11) Sheet thickness parameter ... for selecting the sheet thickness in mm or in. This

automatically sets all the other parameters as well.

(12) Wirespeed parameter ... for selecting the wirespeed in m/min or ipm. Other

parameters that are dependent on this are also automatically adjusted accordingly.

(13) Overtemperature indicator ... lights up if the power source overheats (e.g. be-

cause the duty cycle has been exceeded). For more information on this, see the

“Troubleshooting” section.

(14) HOLD indicator ... every time you finish a welding operation, the actual values for

welding current and voltage are stored, and the “Hold” indicator lights up.

(15) Arc length correction parameter ... for correcting the arc length

- shorter arc length

0 neutral arc length

+ longer arc length

(16) Droplet detachment, arc-force correction and arc-force parameter... has a

different function assigned to it, depending on the process being used.

MIG/MAG standard welding ... for influencing the short-circuiting dynamic at the

instant of droplet transfer

- harder and more stable arc

0 neutral arc

+ soft and low-spatter arc

Loading...

Loading...