99

EN

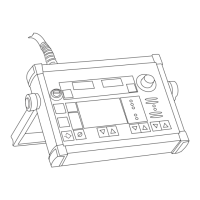

Description of

US control panel

(continued)

MIG/MAG pulsed-arc welding ... continuous correction facility for the droplet-

detachment force

- lower droplet-detachment force

0 neutral droplet-detachment force

+ increased droplet-detachment force

MIG/MAG standard-manual welding ... for influencing the short-circuiting dynamic

at the instant of droplet transfer

0 harder and more stable arc

10 soft, low-spatter arc

Rod electrode (MMA) welding ... for influencing the short-circuiting amperage at the

instant of droplet transfer

0 soft, low-spatter arc

100 harder, more stable arc

(18) JOB n° parameter ... for retrieving parameter records / job numbers that were

previously saved with the “Store” button.

(19) Indicators: F1 / Wirefeed-drive current input / F3 ... for displaying previously

defined parameters

(20) Intermediate arc indicator ... between the dip-transfer arc and the spray arc, a

spatter-prone “intermediate arc” occurs. To alert you to this critical area - and help

you avoid it - the intermediate arc indicator lights up.

(21) Store button ... for accessing the Set-up menu or (in Job Mode) for storing param-

eter settings.

Important! If you press the Store button (21) and the “Material” button (6) at the

same time, the display gives you a read-out of the software version.

If you then press the “Material” button (6) on its own, the version number of the

welding databank appears on the display (e.g.: “0 | 029” = M0029).

If you then press the “Material” button (6) a second time, the number of the wire-

feeder (A, or B in the case of twin-head mounts) and the software version n° of the

wirefeeder appear on the display (e.g.: A 1.5 | 0.23).

To exit, press the Store button (21).

(22) Gas-test button ... for setting the required gas-flow rate on the pressure regulator.

After you press this button, gas will flow out for 30 s. Press the button again to stop

the gas test-flow before the end of this period.

If you press the Store button (21) and the gas-test button (22) at the same time, the

display gives you a read-out of the pre-set gas pre-flow time

(e.g. “GPr | 0.1 s).

- You can alter the gas pre-flow time with the adjusting dial (1)

If you now press the “Process” button (4), the display gives you a read-out of the

pre-set gas post-flow time (e.g. “GPo | 0.5 s”)

- You can alter the gas post-flow time with the adjusting dial (1)

To exit, press the Store button (21).

Loading...

Loading...