1010

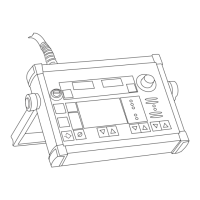

Description of

US control panel

(continued)

(23) “Feeder inching” button ... for feeding the wire electrode into the torch hosepack

with no accompanying flow of gas or current

For information on the various wire-inching sequences that are possible when the

welder presses and holds the “"Feeder inching" button”, see the section headed

“The Set-up Menu”, sub-section “ ‘Process’ parameters”, parameter “Fdi“.

Important! If you press the Store button (21) and the "Feeder inching" button (23)

at the same time, the display gives you a read-out of the pre-set feeder-inching

speed (e.g. “Fdi | 10 m/min” or “Fdi | 393,70 ipm).

- You can alter the feeder-inching speed with the adjusting dial (1)

To exit, press the Store button (21).

(24) Keylock switch ... When the key is in the horizontal position, the following

functions are disabled:

- Selecting the welding process with the “Process” button(s) (4)

- Selecting the operating mode with the “Mode” button(s) (5)

- Selecting the filler metal with the “Material” button(s) (6)

- Accessing the set-up menu with the “Store” button (21)

- Accessing the job-correction menu

Putting the unit

into service

The digital power sources are equipped with an intelligent safety system. After a

possible malfunction or error has been remedied, the power source can be put back into

normal operation again.

For detailed descriptions of error messages, and information on how to remedy any

malfunctions or errors, please refer to the Operating Instructions manual of the power

source.

Troubleshooting

The RCU 4000 remote-control panel can start being used immediately, as soon as its

LocalNet plug has been plugged into the LocalNet connection point on the power

source.

Loading...

Loading...