Frymaster L.L.C., 8700 Line Avenue 71106, P.O. Box 51000, Shreveport, Louisiana 71135-1000

318-865-1711 FAX 318-862-2394

Printed in the United States Service Hotline

Page

15

1-800-24-FRYER

9.4 Troubleshooting Flow Charts:

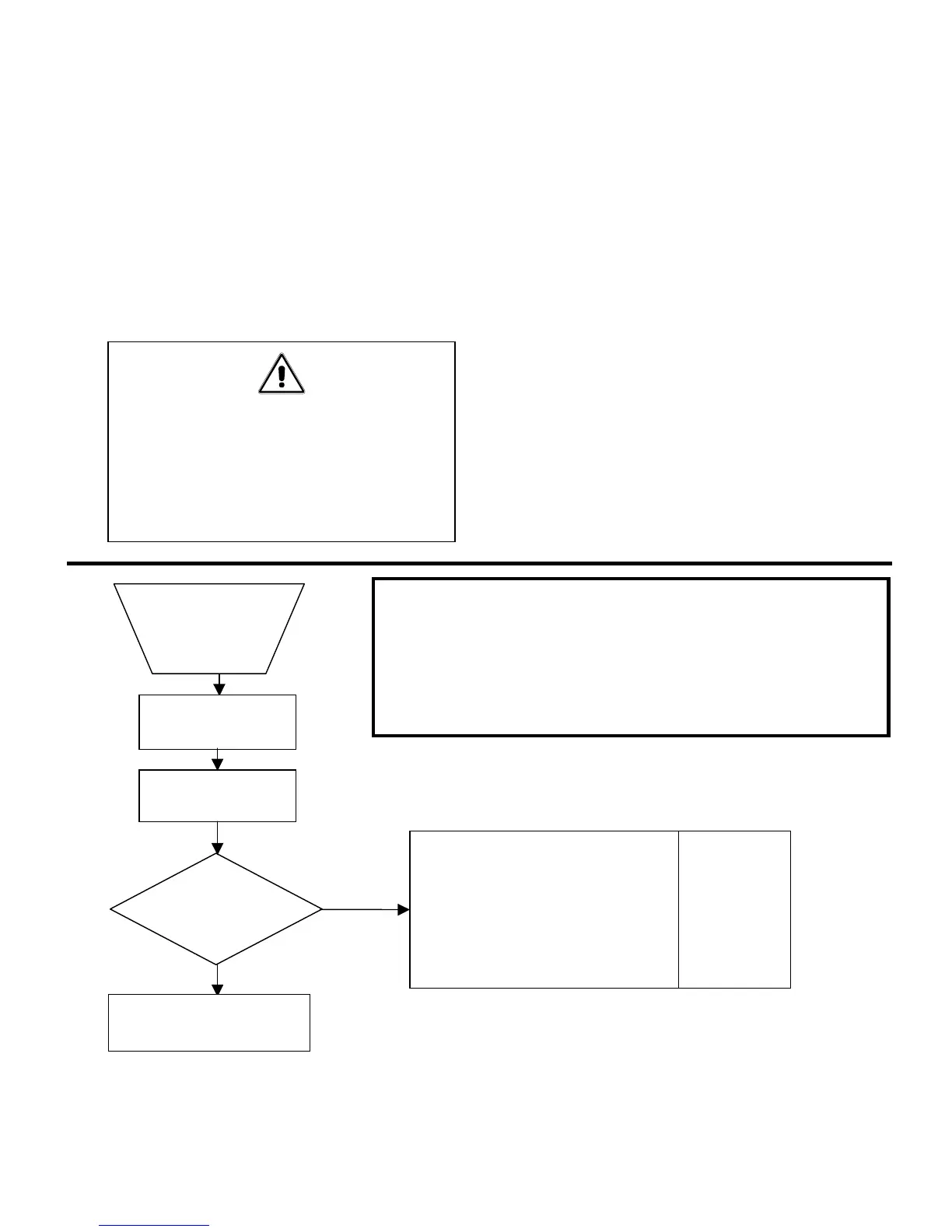

1. Follow the flowchart on pages 15 - 18 to help locate and troubleshoot the most likely

encountered problems. The flowchart will give possible solutions/corrective actions to be

taken.

2. To use the flowchart, start at the top of the diagram. Follow each step in sequence. If the

answer to a question is “yes”, proceed downward to the next step. If the answer is “no”,

follow the arrow to the right to the possible solutions/corrective action boxes.

3. The left box offers possible solutions. The right box gives the corresponding test procedure

to verify the possible solution or corrective action. Test procedures are found on pages 16

– 18.

WARNING!

INSPECTION, TESTING, AND REPAIR

OF ELECTRICAL EQUIPMENT SHOULD

BE PERFORMED BY QUALIFIE

D

PERSONNEL.

Notes: * REdY, HI, or PROB may also appear. REdY

indicates the temperature is near set temp. HI

indicates the temperature is above set temp. PROB

indicates a defective probe circuit (air RTD or heate

RTD).

** STD = Standard troubleshooting test.

N/A = No a

licable test.

YES

Unit powers up

and display reads

LO

Push ON/OFF

switch.

Plug in to power

source.

Set up for test per

section 9.3.1.

Follow each step

in sequence.

1. Incorrect or no voltage

applied.

2. Tripped wall circuit breaker.

3. Blown 20A fuse.

4. Transformer has failed.

5. Computer is faulty.

6. Wiring connection is faulty.

NO

1. STD **

2. STD

3. STD

4. Test A

5. Test B

6. STD

Go to page 16 and

continue.

Loading...

Loading...