3

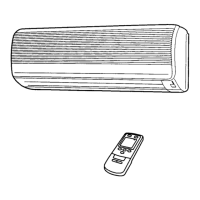

STANDARD PARTS

The following installation parts are furnished. Use them as required.

INDOOR UNIT ACCESSORIES

Name and Shape

Cover plate (left)

Cover plate (right)

Tapping screw (ø4 × 10)

Installation template

Bracket (left)

Bracket (right)

Anchor bolt (M12)

Spring washer

Special nut

Wall bracket

Tapping screw (ø4 × 20)

Coupler heat insulator

(large)

Coupler heat insulator

(small)

Nylon fastener

Q’ty

1

1

2

1

1

1

4

4

4

2

6

1

1

1

Application

For positioning the indoor

unit

For under ceiling type

For suspending the indoor

unit from ceiling

For suspending the indoor

unit on the wall.

For fixing the wall bracket.

For indoor side pipe joint

(Large pipe)

For indoor side pipe joint

(Small pipe)

For fixing the drain hose

Name and Shape

Drain hose

Insulation (drain hose)

VT wire

Q’ty

1

1

1

Application

Adhesive type 70 × 230

For fixing the drain hose

L 280 mm

Left

Right

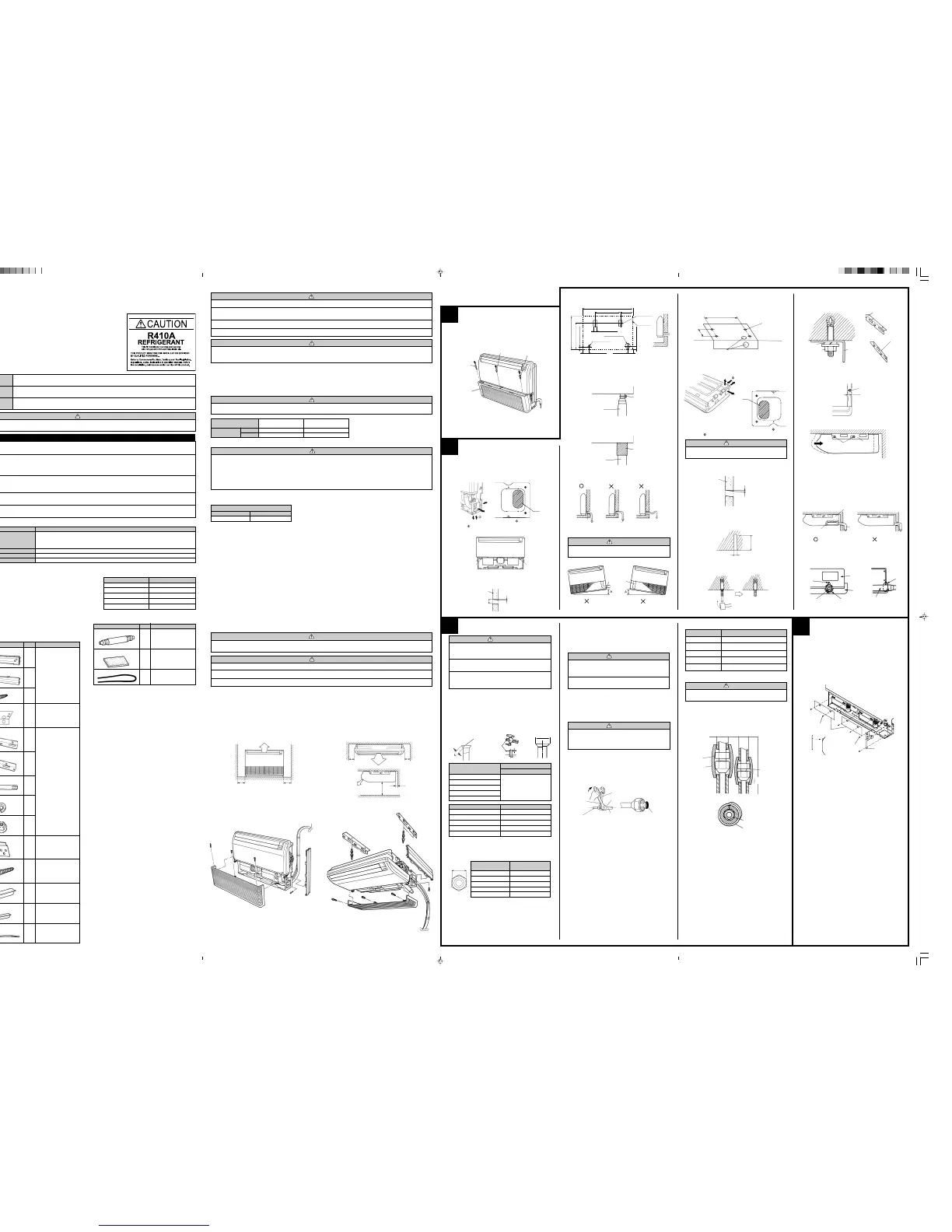

30 cm (12") or more 30 cm (12") or more

••

••

• Under ceiling

Right

Left

Indoor unit

Ceiling

Ceiling

15 cm (6") or more 30 cm (12") or more

2 cm (3/4")

or more

Decide the mounting position with the customer as follows:

INDOOR UNIT

(1) Install the indoor unit level on a strong wall, floor, ceiling which is not subject to vibration.

(2) The inlet and outlet por ts should not be obstructed : the air should be able to blow all over the room.

(3) Install the unit near an electr ic outlet or special branch circuit.

(4) Do not install the unit where it will be exposed to direct sunlight.

(5) Install the unit where connection to the outdoor unit is easy.

(6) Install the unit where the drain pipe can be easily installed.

(7) Take servicing, etc., into consideration and leave the spaces as shown in the figure. Also install the unit where the filter can be removed.

SELECTING THE MOUNTING POSITION

WARNING

Install at a place that can withstand the weight of the indoor and outdoor units and install positively so that the units will not

topple or fall.

CAUTION

1 Do not install where there is the danger of combustible gas leakage.

2 Do not install near heat sources.

3 If children under 10 years old may approach the unit, take preventive measures so that they cannot reach the unit.

••

••

• Floor console

Indoor unit

To outdoor unit

Floor console

Indoor unit

To outdoor unit

Under ceiling

100 mm (4")

1

INSTALLATION PROCEDURE

Install the room air conditioner as follows:

Machine screw

Tapping screw

Intake grille

Tapping screw

2

The drain hose can be connected to either the left or right side.

Drain hose

(Right side)

Drain hose

(Left side)

When installing set to wall install the accessory wall bracket at the posi-

tion as shown in the figure, and mount the set to it.

Wall

Outdoor side

6 mm (1/4")

Indoor side

Nylon fastener

Drain pan

Drain hose

Insulation (Drain hose)

Drain pan

Drain hose

Arrange the drain

hose lower than

this portion.

Drain hose

Drain hose

When the directions are selected, drill a 10 cm (4") dia. hole on the wall so

that the hole is tilted downward toward the outdoor for smooth water flow.

When the pipe is led out from the rear, make a hole as shown in the figure,

at the position shown.

50 cm (20")

24.5 cm

(

9-5/8"

)

6.5 cm (2-1/2")

10 cm (4") hole

5 cm (2") hole

12.5 cm (5") 10 cm (4")

6.5 cm (2-1/2")

65.5 cm (26")

53 cm (21")

4.5 cm (1-3/4")

Wall bracket

Side of set

99 cm (39")

2. INSTALLING THE DRAIN HOSE

Select whether the drain hose will be connected to the left or right side.

Insert the drain hose into the drain pan, then secure the drain hose with a

nylon fastener.

CAUTION

Do not install the unit so that the drain hose side is too

high. Height A should be less than 5 mm.

Be sure to arrange the drain hose so that it is leveled lower than the drain

hose connecting port of the indoor unit.

Wrap the insulation (drain hose) around the drain hose connection.

Remark: The main unit can be wired before the indoor unit is in-

stalled. Select the most appropriate installation order.

PREPARING INDOOR UNIT

INSTALLATION

1. REMOVE THE INTAKE GRILLE

Open the intake grille and remove the three screws.

B. UNDER CEILING TYPE

Using the installation template, drill holes for piping and anchor bolts (for

holes).

900 mm (35-7/16")

200 mm

(7-7/8" )

Drilling position

for piping

Installation

template

Drilling position

for anchor bolt

Ceiling

Wall

1. DRILLING FOR PIPING

Select piping and drain directions.

CAUTION

Install the drain hose at the rear; it should not be installed

on the top or right side.

When the directions are selected, drill 80 mm (3-1/8") and 50 mm (2") or

150 mm (6") dia. hole on the wall so that the hole is tilted downward to-

ward the outdoor for smooth water flow.

Wall

6 mm (1/4")

Indoor side Outdoor side

2. DRILLING HOLES FOR ANCHOR BOLTS AND

INSTALLING THE ANCHOR BOLTS

With a concrete drill, drill four 12.7 mm (1/2") dia. holes.

60 to 70 mm

(2-3/8" to 2-3/4")

ø 12.7 mm (1/2")

3. INSTALLING BRACKETS

Install the brackets with nuts, washers and spring washers.

Insert the anchor bolts into the drilled holes, and drive the pins completely

into the anchor bolts with a hammer.

Apply the indoor unit to the brackets.

Spring

washer

Special nut

Bracket

Bracket (Left)

Bracket (Right)

4. INSTALLING INDOOR UNIT

Reset the hex bolts as shown in the figure.

Hex bolt

Indoor unit

8 to 13 mm

(5/16" to 1/2")

Bolt

Bracket

Indoor unit

Now, securely tighten the hex bolts in both sides.

5. INSTALLING THE DRAIN HOSE

Select whether the drain hose will be connected to the left or right side.

Insert the drain hose into the drain pan, then secure the drain hose with a

nylon fastener.

Wrap the insulation (drain hose) around the drain hose connection.

Be sure to arrange the drain hose so that it is leveled lower than the drain

hose connecting port of the indoor unit.

Remove the hole cover.

Drain hose

Arrange the drain hose

lower than this portion.

VT wire

hole

Pass the drain hose

through here.

Base (Bottom)

Cut the grille

VT wire

Drain hose

Intake grille

When drain hose is arranged backward.

Secure the drain hose with the VT wire.

CAUTION

Be sure to apply the pipe against the port on the indoor

unit correctly. If the centering is improper, the flare nut

cannot be tightened smoothly. If the flare nut is forced to

turn, the threads will be damaged.

(2) Install the outdoor unit wall cap (supplied with the optional installation

set or procured at the site) to the wall hole pipe.

(3) Connect the outdoor unit and indoor unit piping.

(4) After matching the center of the flare surface and tightening the nut

hand tight, tighten the nut to the specified tightening torque with a

torque wrench.

3. CONNECTION PIPES

(1) Center ing the pipe against port on the indoor unit, turn the flare nut

with your hand.

Be sure that the small pipe is completely installed before connecting

the large the pipe.

Tighten with two wrenches.

Wrench (fixed)

Flare nut

Connection pipe

Indoor unit

pipe

Torque wrench

To prevent gas leakage,

coat the flare surface with

alkylbenzene oil (HAB).

Do not use mineral oil.

Flare nut

6.35 mm (1/4 in.) dia.

9.52 mm (3/8 in.) dia.

12.7 mm (1/2 in.) dia.

15.88 mm (5/8 in.) dia.

19.05 mm (3/4 in.) dia.

Tightening torque

14 to 18 N

·

m (140 to 180 kgf

·

cm)

33 to 42 N

·

m (330 to 420 kgf

·

cm)

50 to 62 N

·

m (500 to 620 kgf

·

cm)

63 to 77 N

·

m (630 to 770 kgf

·

cm)

100 to 110 N

·

m (1,000 to 1,100 kgf

·

cm)

CAUTION

Be sure to connect the large pipe after connecting the small

pipe completely.

Do not remove the cap from the connection pipe before connecting

the pipe.

Flare nut tightening torque

4. HEAT INSULATION ON THE PIPE JOINTS

(INDOOR SIDE ONLY)

Put coupler heat insulator on the joints (indoor side only).

Indoor unit

No gap

Coupler heat

insulator

(large)

Coupler heat

insulator (small)

No gap

Coupler heat

insulation

Be sure to overlap

the insulation

Large pipe Small pipe

INSTALLATION

INSTRUCTION SHEET

(PART NO. 9375754020)

For authorized service personnel only.

Contents of change

Pressure is high and cannot be measured with a conventional gauge. To prevent erroneous mixing of other

refrigerants, the diameter of each port has been changed.

It is recommended the gauge with seals –0.1 to 5.3 MPa (–76 cmHg to 53 kgf/cm

2

) for high pressure. –0.1 to

3.8 MPa (–76 cmHg to 38 kgf/cm

2

) for low pressure.

To increase pressure resistance, the hose mater ial and base size were changed.

A conventional vacuum pump can be used by installing a vacuum pump adapter.

Special gas leakage detector for HFC refrigerant R410A.

Tool name

Gauge manifold

Charge hose

Vacuum pump

Gas leakage detector

Floor Console/Under Ceiling Dual Type

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

0.80 mm

0.80 mm

0.80 mm

1.00 mm

1.20 mm

Pipe outside diameter

Thickness

Thicknesses of Annealed Copper Pipes (R410A)

CONNECTION PIPE REQUIREMENT

CAUTION

Refer to the installation instruction sheet of the outdoor unit for description of the length of connecting pipe or for difference of

its elevation.

For authorized service personnel only.

WARNING

1 For the air conditioner to operate satisfactorily, install it as outlined in this installation instruction sheet.

2 Connect the indoor unit and outdoor unit with the air conditioner piping and cords available from our standards parts. This instal-

lation instruction sheet describes the correct connections using the installation set available from our standard parts.

3 Installation work must be performed in accordance with national wiring standards by authorized personnel only.

4 Do not turn on the power until all installation work is complete.

CAUTION

This installation instruction sheet describes how to the indoor unit only.

To install the outdoor unit, refer to the installation instruction sheet included with the outdoor unit.

To install the remote controller, refer to the installation instruction sheet included with the remote controller unit.

••

••

• Be careful not to scratch the air conditioner when handling it.

••

••

• After installation, explain correct operation to the customer, using the operating manual.

••

••

• Let the customer keep this installation instruction sheet because it is used when the air conditioner is serviced or moved.

MODEL

Diameter

Small

Large

18,000 24,000

BTU/h model BTU/h model

6.35 mm (1/4 in.) 6.35 mm (1/4 in.)

12.70 mm (1/2 in.) 15.88 mm (5/8 in.)

ELECTRICAL REQUIREMENT

CAUTION

Install heat insulation around both the gas and liquid pipes. Failure to do so may cause water leaks.

Use heat insulation with heat resistance above 120 °C. (Reverse cycle model only)

In addition, if the humidity level at the installation location of the refrigerant piping is expected to exceed 70 %, install heat

insulation around the refrigerant piping. If the expected humidity level is 70-80 %, use heat insulation that is 15 mm or thicker and

if the expected humidity exceeds 80 %, use heat insulation that is 20 mm or thicker.

If heat insulation is used that is not as thick as specified, condensation may form on the surface of the insulation.

In addition, use heat insulation with heat conductivity of 0.045 W/(m·K) or less (at 20 °C).

••

••

• Use conformed cord with Type 245 IEC57.

••

••

• Install all electrical works in accordance to the standard.

••

••

• Install the disconnect device with a contact gap of at least 3 mm in all poles nearby the units. (Both indoor unit and outdoor unit)

Connection cord (mm

2

)

MAX.

2.5

MIN.

1.5

••

••

• Use pipe with water-resistant heat insulation.

CONNECTING THE PIPE

CAUTION

1 Do not use mineral oil on flared part. Prevent mineral

oil from getting into the system as this would reduce

the lifetime of the units.

2 While welding the pipes, be sure to blow dry nitrogen

gas through them.

3 The maximum lengths of this product are shown in the

table. If the units are further apart than this, correct

operation can not be guaranteed.

1. FLARING

(1) Cut the connection pipe to the necessar y length with a pipe cutter.

(2) Hold the pipe downward so that cuttings will not enter the pipe and

remove the burrs.

(3) Inser t the flare nut (always use the flare nut attached to the indoor

and outdoor units respectively) onto the pipe and perform the flare

processing with a flare tool.

Use the special R410A flare tool, or the conventional flare tool.

Check if [L] is flared uniformly

and is not cracked or scratched.

B

Die

A

Pipe

Width across

flats

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

0 to 0.5

Pipe outside diameter

Dimension A

(mm)

Flare tool for R410A, clutch type

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

9.1

13.2

16.6

19.7

24.0

Pipe outside diameter

Dimension B

(mm)

0

-0.4

When using conventional flare tools to flare R410A pipes, the dimension

A should be approximately 0.5 mm more than indicated in the table (for

flaring with R410A flare tools) to achieve the specified flaring. Use a thick-

ness gauge to measure the dimension A.

Pipe outside

diameter

Width across flats

of Flare nut

17 mm

22 mm

26 mm

29 mm

36 mm

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

2. BENDING PIPES

The pipes are shaped by your hands. Be careful not to collapse them.

Do not bend the pipes in an angle more than 90°.

When pipes are repeatedly bend or stretched, the material will harden,

making it difficult to bend or stretch them any more. Do not bend or stretch

the pipes more than three times.

CAUTION

1 To prevent breaking of the pipe, avoid sharp bends.

Bend the pipe with a radius of curvature of 150 mm or

over.

2 If the pipe is bent repeatedly at the same place, it will

break.

(Continued to the next page)

230 cm (90-1/2")

or more

Floor

4

(1) Remove the barriers by removing the 4 fixing screws (2 screws each).

(2) Remove the RFM base by removing the 2 fixing screws and unhooking

the 1 hook.

(3) After completing the work, install the barr iers and RFM base as they

were originally.

INDOOR UNIT INSTALLATION

A. FLOOR CONSOLE TYPE

1. DRILLING FOR PIPING

Select piping and drain directions.

The piping and drain can be made in three directions as shown below.

BARRIER AND RFM BASE

REMOVAL

BARRIER AND RFM BASE REMOVAL

AND INSTALLATION

Install the barriers in the correct direction.

Hook

Barrier

Fixing screw

(2 positions)

Fixing screw

(2 positions)

RFM base

This air conditioner uses new refrigerant HFC (R410A).

The basic installation work procedures are the same as conventional refrigerant models.

However, pay careful attention to the following points:

1 Since the working pressure is 1.6 times higher than that of conventional refrigerant models, some of the piping and

installation and service tools are special. (See the table below.)

Especially, when replacing a conventional refrigerant model with a new refrigerant R410A model, always replace the

conventional piping and flare nuts with the R410A piping and flare nuts.

2 Models that use refrigerant R410A have a different charging port thread diameter to prevent erroneous charging with

conventional refrigerant and for safety. Therefore, check beforehand. [The charging port thread diameter for R410A is

1/2 UNF 20 threads per inch.]

3 Be more careful that foreign matter (oil, water, etc.) does not enter the piping than with refrigerant models. Also, when

storing the piping, securely seal the openings by pinching, taping, etc.

4 When charging the refrigerant, take into account the slight change in the composition of the gas and liquid phases, and

always charge from the liquid phase side whose composition is stable.

Special tools for R410A

Copper pipes

It is necessary to use seamless copper pipes and it is desirable that the

amount of residual oil is less than 40 mg/10 m. Do not use copper pipes

having a collapsed, deformed or discolored portion (especially on the interior

surface). Otherwise, the expansion valve or capillary tube may become

blocked with contaminants.

As an air conditioner using R410A incurs pressure higher than when

using conventional refrigerant, it is necessary to choose adequate materials.

Thicknesses of copper pipes used with R410A are as shown in the table.

Never use copper pipes thinner than that in the table even when it is

available on the market.

DANGER

This mark indicates procedures which, if improperly performed, are most likely to result in the death of or

serious injury to the user or service personnel.

WARNING

This mark indicates procedures which, if improperly performed, might lead to the death or serious injury of

the user.

CAUTION

This mark indicates procedures which, if improperly performed, might possibly result in personal harm to

the user, or damage to property.

DANGER

Never touch electrical components immediately after the power supply has been turned off. Electrical shock may occur. After

turning off the power, always wait 5 minutes or more before touching electrical components.

Loading...

Loading...