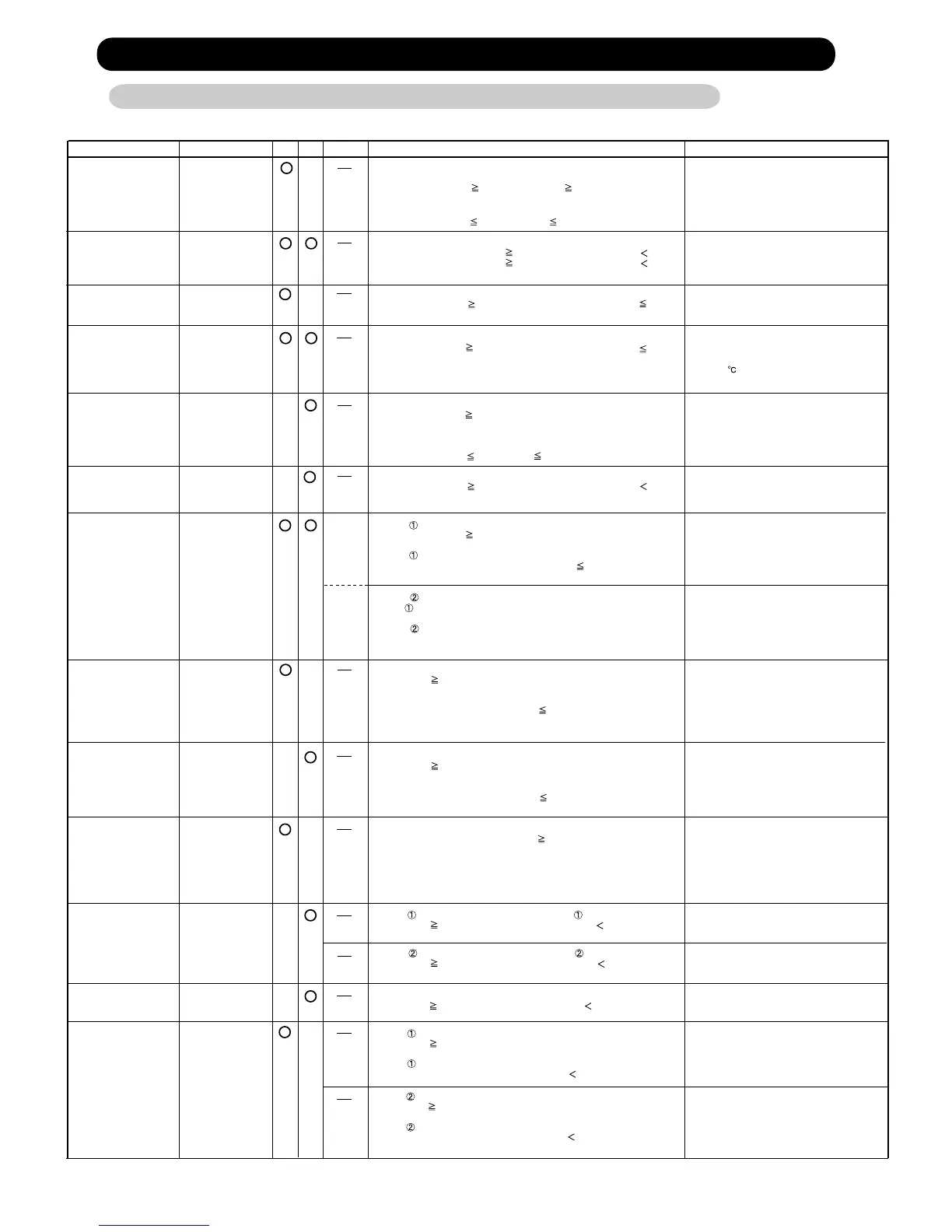

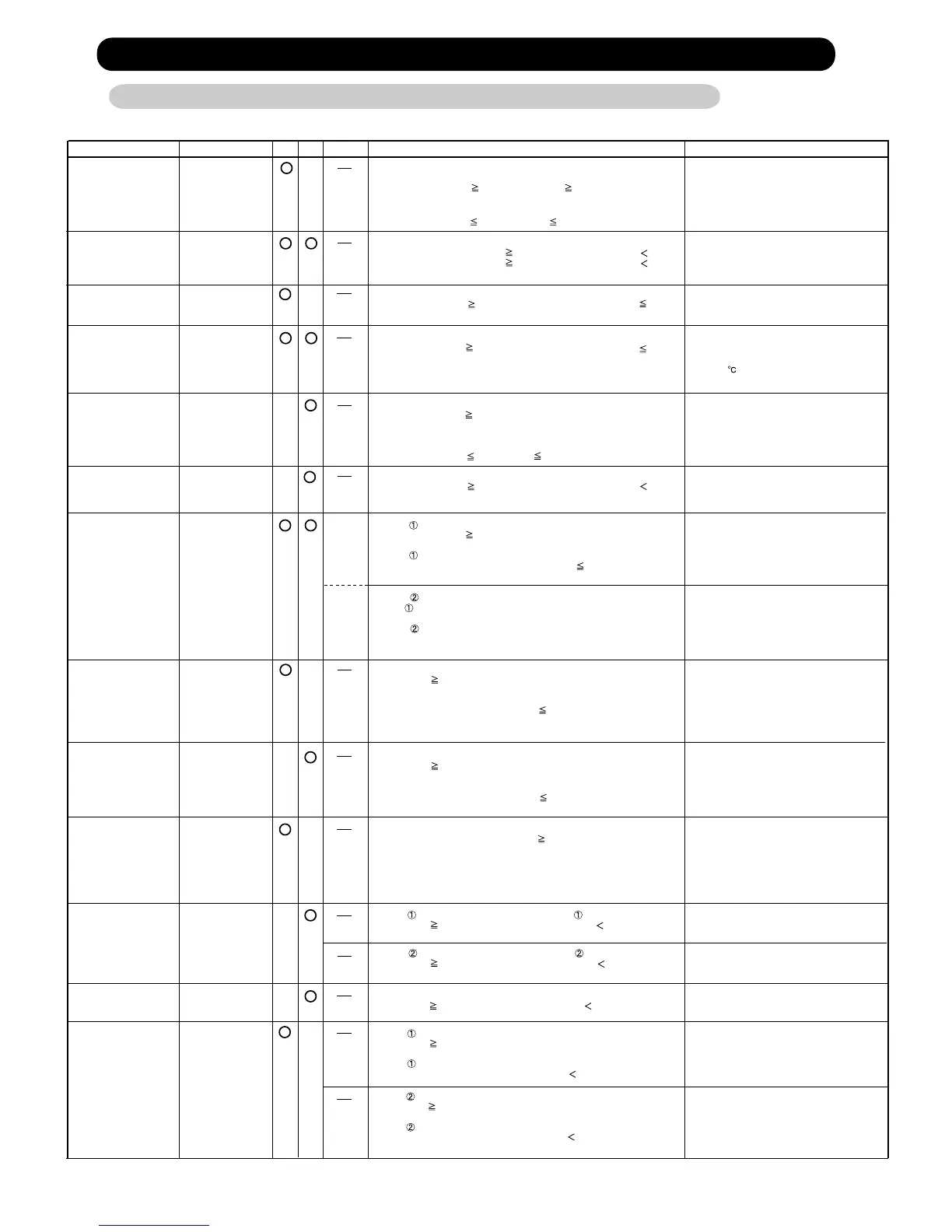

2-6 PROTECTIVE FUNCTION

02-13

2-6-1 Protective Function List

Protective Function

Detect Parts

Operating Condition

Operation

Discharge Temp

Protection 1

Discharge Temp

Thermistor

Discharge Temp

Protection 2

Discharge Temp

Thermistor

Discharge Temp

Protection 3

Discharge Temp

Thermistor

High Pressure

Protection 1

High Pressure

Sensor

High Pressure

Protection 4

High Pressure

Sensor

COOL HEAT

<Starting conditions>

3 minutes have elapsed since the start of operation and

(discharge temperature 100°C or suction SH 10°C accumulated time

30 minutes)

<Reset conditions>

Discharge temperature 95°C and suction 7°C

EEV of operating indoor unit gradually opened

<Starting conditions>

Cooling: Discharge temperature 95°C

Heating: Discharge temperature 102°C

<Reset conditions>

Discharge temperature 90°C

Discharge temperature 97°C

EEV2 + 30pls/30 secs

<Starting conditions>

Discharge temperature 107°C

<Reset conditions>

Discharge temperature 105°C

Outdoor unit rotation execution

* After rotation has been executed once;

it is executed every 15 minutes.

Discharge Temp

Protection 4

Discharge Temp

Thermistor

< starting condition>

Discharge temperature 105°C

<Pattern reset condition>

Discharge temperature 100°C

INV compressor speed -6rps every 30 secs

Speed rise prohibited,

when discharge temperature becomes lower

than 105 , prohibit the rotational speed rise

of the compressor.

Discharge Temp

Protection 5

Discharge Temp

Thermistor

<Starting conditions>

Discharge temperature 95°C and EEV1=500pls

<Reset conditions>

2 minutes have elapsed and

(discharge temperature 90°C or EEV1 400pls)

Expansion valve of stopped indoor unit gradually

opened

(upper limit 200pls)

Discharge Temp

Protection 6

Discharge Temp

Thermistor

<Starting conditions>

Discharge temperature 90°C

<Reset conditions>

Discharge temperature 90°C

EEV1: Forcefully OPEN

Discharge Temp

Protection Stop

Discharge Temp

Thermistor

<Pattern starting condition>

Discharge temperature fixed value (INV: 110°C, constant speed: 115°C)

<Pattern reset condition>

3 minutes have elapsed and discharge temperature 80°C

Corresponding compressor stopped

<Pattern starting condition>

Pattern generated 2 times within 40 minutes

<Pattern reset condition>

Error reset (push button SW) executed after power turned on again

Corresponding compressor stopped

(permanent stop)

Error display

<Starting conditions>

High-pressure 3.94MPa

<Reset conditions>

Fixed time has elapsed and high-pressure 3.70MPa

* Fixed time when SV1: ON 180 secs, when SV2: ON 30 secs

At INV independent operation: SV2 ON

At constant speed independent operation:

SV1 ON

High Pressure

Protection 2

High Pressure

Sensor

<Starting conditions>

High-pressure 3.60MPa

<Reset conditions>

3 minutes have elapsed and high-pressure 2.80MPa

At INV independent operation: SV2 ON

When still insufficient: SV1 ON + SV2 ON

At INV + constant speed operation, constant

speed independent operation: SV1 ON

High Pressure

Protection 3

High Pressure

Sensor

<Starting conditions>

Fixed time has elapsed and high-pressure 3.50MPa

(* Fixed time at start of operation: 10 secs, after operation execution: 20 secs)

<Reset conditions>

Operation (fan speed 1 step increase) complete

Fan speed 1 step increase

<Pattern starting condition>

High-pressure 3.30MPa

<Pattern starting condition>

High-pressure 3.50MPa

<Pattern reset condition>

High-pressure 3.3MPa

<Pattern reset condition>

High-pressure 3.5MPa

Fan speed lowered/every 30 secs

Fan lowest speed (300rpm) fixed

DISPLAY

P1

EA11

(INV)

EA21

(CONST)

High Pressure

Protection 5

High Pressure

Sensor

Abnormal High

Pressure Protection

Control

High Pressure

Sensor

<Starting conditions>

High-pressure 3.20MPa

Compressor capacity lowered/every 15 secs

<Pattern starting condition>

High-pressure 3.78MPa

<Pattern reset condition>

After 25 seconds have elapsed and high-pressure 3.70MPa

Compressor capacity rise prohibited

<Reset conditions>

High-pressure 3.20MPa

<Pattern starting condition>

High-pressure 3.90MPa

<Pattern reset condition>

After 25 seconds have elapsed and high-pressure 3.78MPa

Compressor capacity lowered every 30 secs

Loading...

Loading...