6. SYSTEM DESIGN

[Installation precautions]

Contents Countermeasures (Reference)

When inside

the ceiling

is high

temperature

and high

humidity

When the indoor unit is installed where the

inside of the ceiling is 30°C (86°F) RH80%

or greater, the dew point temperature of the

outer perimeter may become higher than the

cabinet surface temperature and moisture will

condense on the surface of the cabinet and

water drops may fall inside the room.

eer to ig.

In addition, the humidity may vary

considerably the same as when the inside of

the ceiling is close to hermetically sealed and

used as the outside air intake path.

1) Add heat insulating material

to the outside of the indoor

unit cabinet.

*Regarding the cassette type,

use of the “high humidity

correspondence kit (option)”

is recommended.

2) Strengthen the heat

insulating material of the

refrigerant piping and drain

piping also

eer to ig.

3) When the humidity inside

the ceiling changes

considerably, install a

ventilation port

Contents Countermeasures (Reference)

When using

an external

duct

When using an external duct to take in new

fresh air, etc., condensation may form on

the surface of the duct due to the effect of

the outside air temperature and the humidity

inside the ceiling.

1) Always perform heat

insulation processing.

(Heat insulating material:

Glass wool 25mm (31/32 in.)

thick or more.)

When the

remote

controller

installation site

is bad

If the cold or warm air blown out from the air

conditioner directly contacts the thermostat

section of the remote controller, the outlet

temperature of the air conditioner may be

sensed and room temperature control will be

different from the room temperature and “not

cooled” or “not heated” or other trouble may

occur.

In addition, there is the possbility that the

same kind of trouble may also occur when the

remote controller is effected by direct sunlight.

1) Install the remote controller

where it will not be directly

exposed to the cold or hot

air.

2) Install the remote controller

where it will not be directly

exposed to sunlight or

strong lighting.

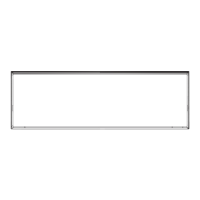

Moist air curve

Condition which

requires addition of

outside heat insulation

Relative humidity 80%

Dry bulb temperature 30°C (86°F)

Fig.A

Work method when reinforcing the heat insulation

of on-site piping

Fig.B

Slit of heat insulating

material facing upward

Covered gas pipe

(heat insulation

strengthened)

Heat insulating material

(procured at the site)

Small exposed part of

copper pipe is desirable.

Fit tightly (purpose is

to cover the sealant)

Binding material

Flare connection

To indoor unit

Heat insulation

reinforcement material

(procured at the site)

- (06 - 152) -

SYSTEM

DESIGN

SYSTEM

DESIGN

Loading...

Loading...